GaN power tube gate drive circuit with controllable opening rate

A gate drive circuit and power tube technology, applied in the direction of output power conversion devices, electrical components, climate sustainability, etc., can solve the problem of reducing the turn-on speed of GaN power tubes, fixed current-limiting resistors that cannot be adjusted freely, and difficulties in obtaining Miller platform and other issues to achieve the effects of preventing stress, improving reliability, and reducing dv/dt and di/dt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner and principle of the present invention will be described in detail below in conjunction with the drawings.

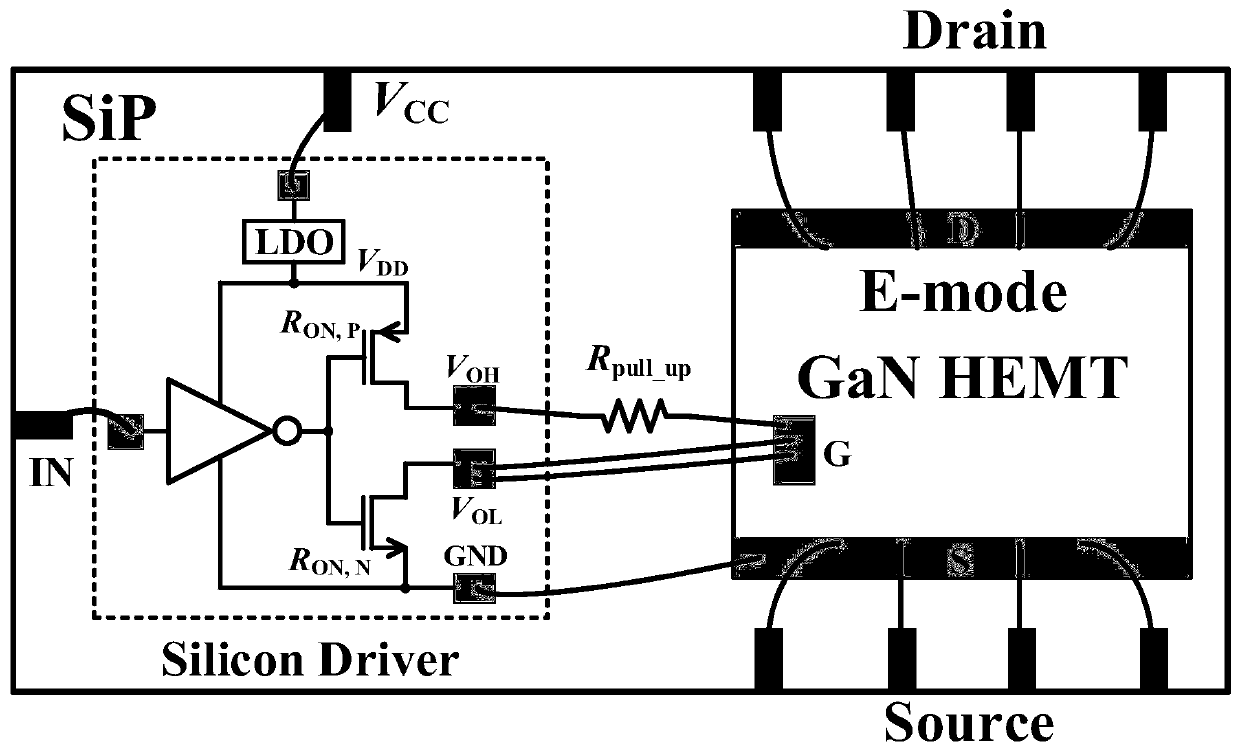

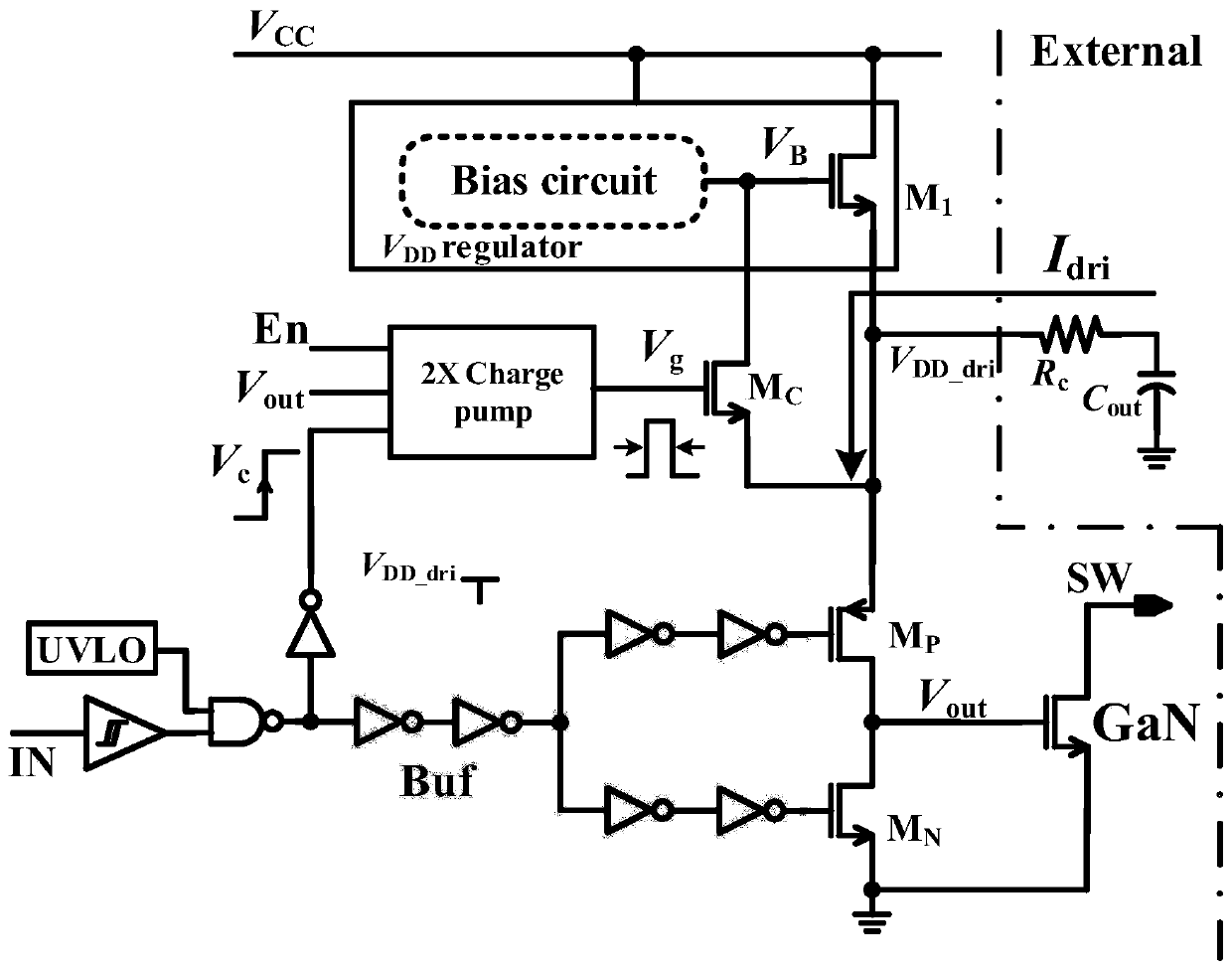

[0045] A GaN power tube gate drive circuit with controllable turn-on rate proposed by the present invention includes an internal power generation module, a gate drive module, a charge pump module, and an external capacitor C out and current limiting resistor R C , where the internal power generation module, gate drive module and charge pump module are integrated in the chip, and the external capacitor C out and current limiting resistor R C It is arranged outside the chip, which solves the problem that the gate driver and GaN power tube are mixed in the traditional SiP package, so that the current limiting resistor is fixed inside the package and cannot be adjusted freely.

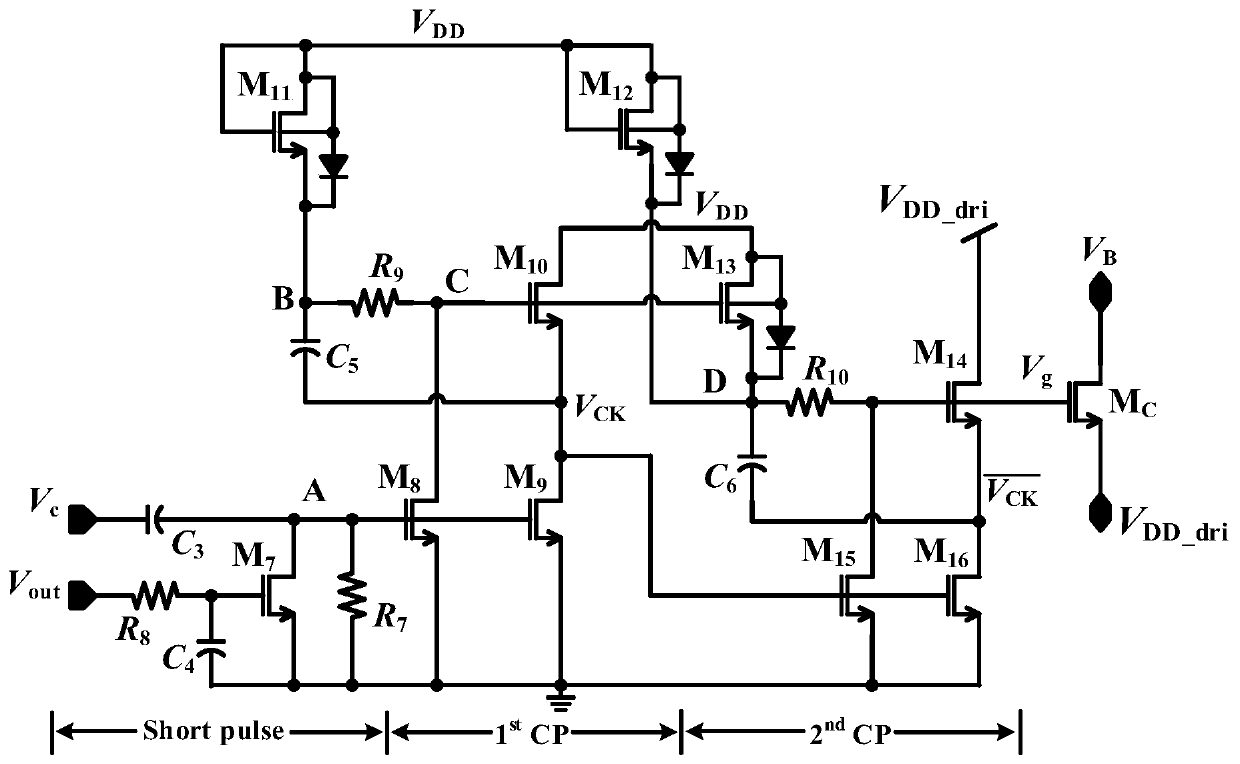

[0046] The internal power generation module is used to generate the first power supply V for powering the gate drive module DD_dri , the first power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com