Green preparation method of nitroglycerin

A technology of nitroglycerin and nitroglycerin dichloromethane, applied in the field of green preparation of nitroglycerin, to achieve the effect of solving a large amount of heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

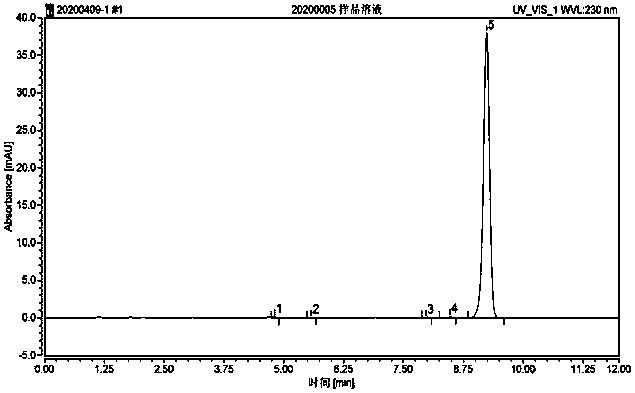

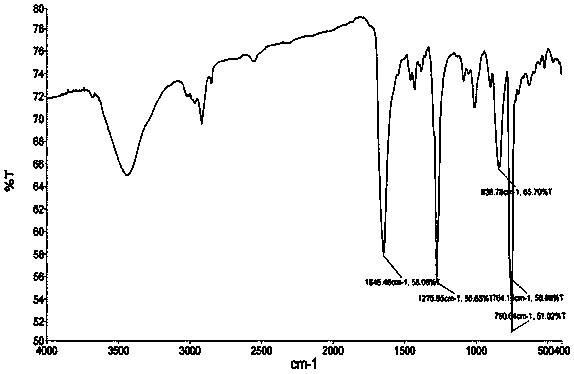

[0073] Preparation of 10% Nitroglycerin in Dichloromethane Solution

[0074] Concentrated sulfuric acid and fuming nitric acid are mixed at a speed ratio of 1:1 through the microreactor chip (1); glycerol and methylene chloride are input into the mixer (2) at a speed ratio of 0.2:2, and the microreactor chip (1 ) mixed acid solution and the solution of the mixer (2) are input into the microreactor chip (3), (4), (5) with the speed ratio of 2:2.75, and the retention time of the reaction solution in the microreactor is 10min to 30min, the reaction solution is input from the microreactor (5) to the Zaiput liquid-liquid separator (6), the acid solution is input to the waste liquid processor, the organic phase is mixed with water to the input mixer (7), and then input to the Zaiput liquid-liquid Separator (8), the water phase is input to the waste liquid processor, the organic phase and saturated salt solution are input to the Zaiput liquid-liquid separator (9), the water phase is ...

Embodiment 2

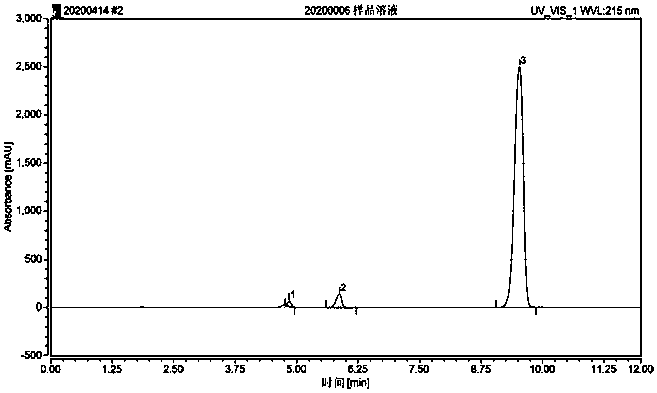

[0076] Green granules of nitroglycerin

[0077] A 10% concentration of nitroglycerin dichloromethane solution (10 ml) was pumped into a hot-melt extruder, 9 grams of lactose granules were added, granulated in a wet granulation mode, and vacuum-dried to obtain green granules of nitroglycerin.

Embodiment 3

[0079] Green freeze-dried granules of nitroglycerin (1)

[0080] 10% nitroglycerin dichloromethane solution 20 ml, polyvinylpyrrolidone 5 grams, lactose 18 grams; add appropriate amount of water for injection, slowly add 0% nitroglycerin dichloromethane solution, polyvinylpyrrolidone, lactose, and stir until After complete mixing, stir the bag for about 2-4 hours; vacuum freeze-dry to obtain green freeze-dried granules of nitroglycerin (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com