Fiber laser dual-track cladding equipment for high-parameter waste incineration boiler membrane water wall

A membrane-type water-cooled wall and waste incineration technology, which is applied in metal material coating process, coating and other directions, can solve the problems of wasting nickel-based superalloy materials, large deformation of membrane-type water-cooling wall, and low efficiency of multi-layer surfacing. Achieve the effect of improving work efficiency and processing quality, solving resource waste, and improving cladding processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

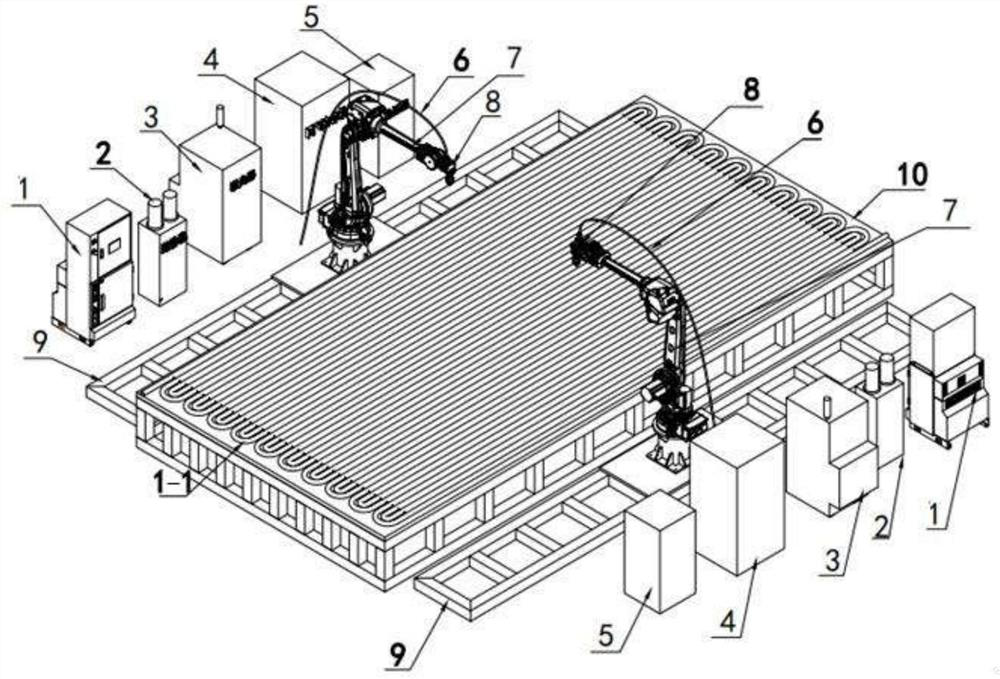

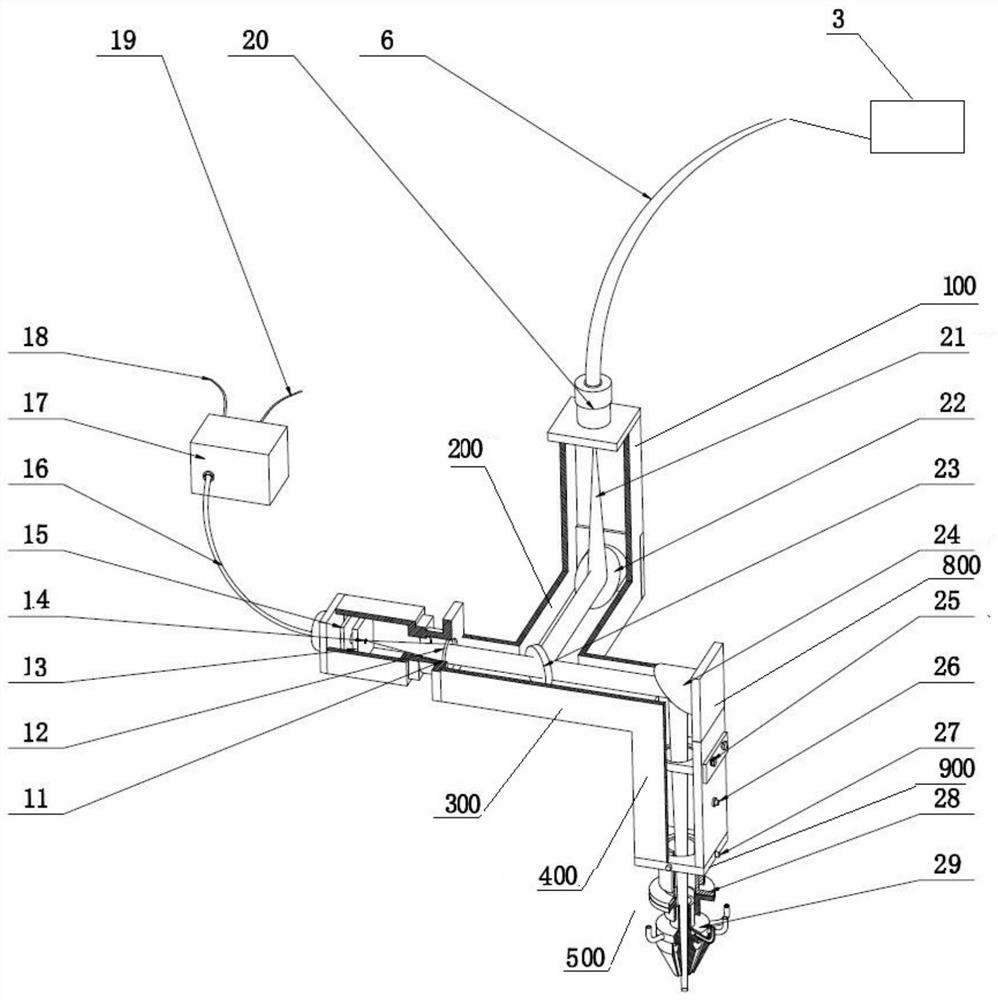

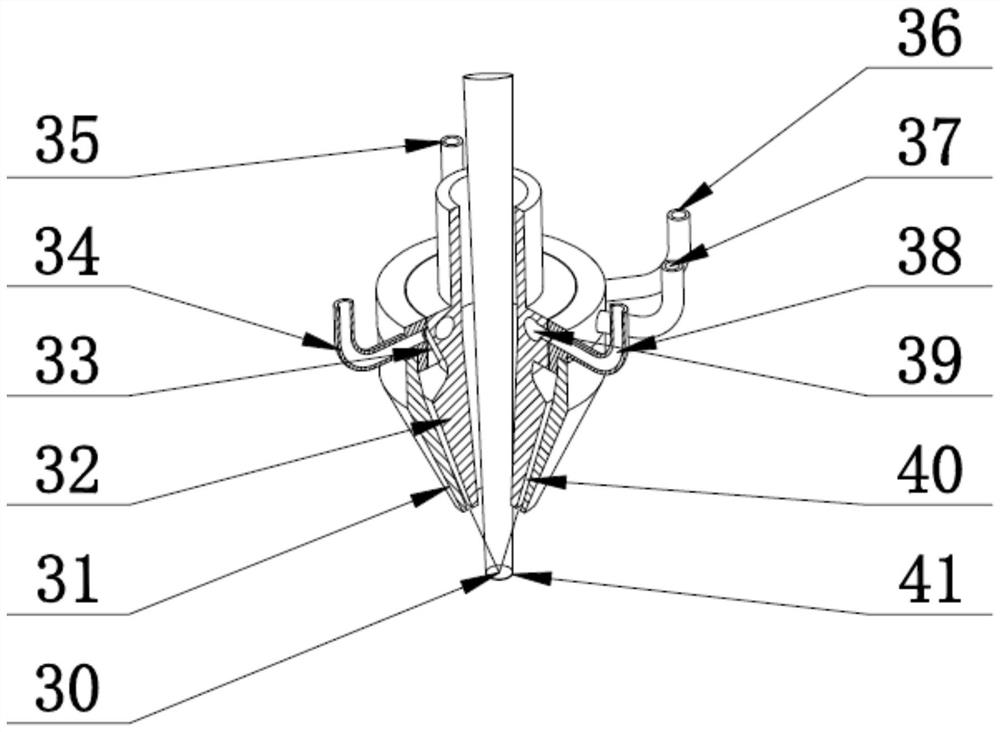

[0031]A fiber laser double-track cladding equipment for a membrane-type water-cooled wall of a high-parameter waste incineration boiler, comprising a machine tool platform 10, a slide rail 9, a robot 7, a laser cladding unit 8, a powder feeder 2, and an optical fiber 6; the machine tool platform 10 It is fixedly installed on the horizontal plane, and along the two sides parallel to the machine tool platform 10, a set of slide rails 9 are independently installed; the robot 7 is fixedly installed on each set of slide rails 9; the laser cladding unit 8 is fixedly installed on the top of the robot 7, and the inner end is connected with the optical fiber 6.

[0032] At the same time, after the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com