Composition for drilling and pouring, preparation method thereof and wall protection mud

A technology of drilling and pouring and composition, which is applied in the direction of drilling composition, chemical instruments and methods, etc., which can solve the problems of increasing the resistance of underwater pouring concrete, reducing the radius of concrete flow, and affecting the quality of the pile body, etc., to achieve enhanced The effect of retaining wall capacity, improving the quality of pile formation, and reducing the difficulty of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

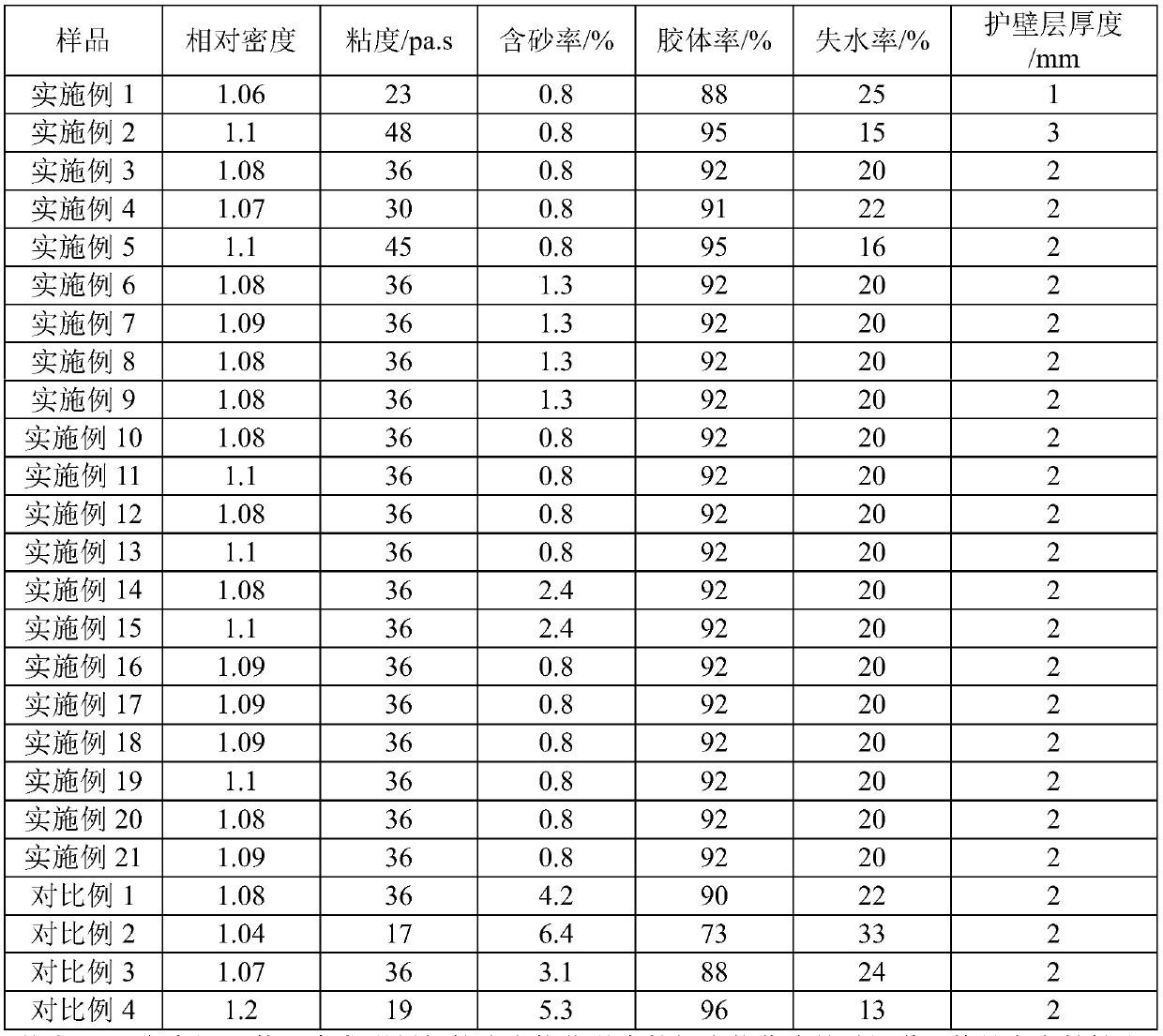

Examples

Embodiment 1

[0029] A kind of preparation method for the composition of borehole perfusion comprises the steps:

[0030] Add 2kg of wall protection agent potassium polyacrylate, 20kg of tackifier polyacrylamide, 8kg of fast solvent sodium chloride, 13kg of precipitant polyaluminum chloride and 13kg of stabilizer sodium hydroxide into the sealed mixing tank and stir for 8 minutes, and stir evenly. The composition can be prepared.

Embodiment 2

[0032] A kind of preparation method for the composition of borehole perfusion comprises the steps:

[0033] Add 15kg wall protection agent potassium polyacrylate, 65kg tackifier polyacrylamide, 8kg instant solvent sodium chloride, 13kg precipitant polyaluminium chloride and 13kg stabilizer sodium hydroxide into the sealed mixing tank and stir for 8 minutes, and stir evenly. The composition can be prepared.

Embodiment 3

[0035] A kind of preparation method for the composition of borehole perfusion comprises the steps:

[0036] Add 8kg wall protection agent potassium polyacrylate, 45kg tackifier polyacrylamide, 8kg instant solvent sodium chloride, 13kg precipitant polyaluminum chloride and 13kg stabilizer sodium hydroxide into the sealed mixing tank and stir for 8min, and stir evenly. The composition can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com