Flexible wax and method of making same

A flexible and wax composition technology, which is applied in the direction of candle preparation equipment, fatty acid preparation/refining, wax coating, etc., can solve the problems of expensive and scarce, and achieve the effects of fast cooling, increased flexibility and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

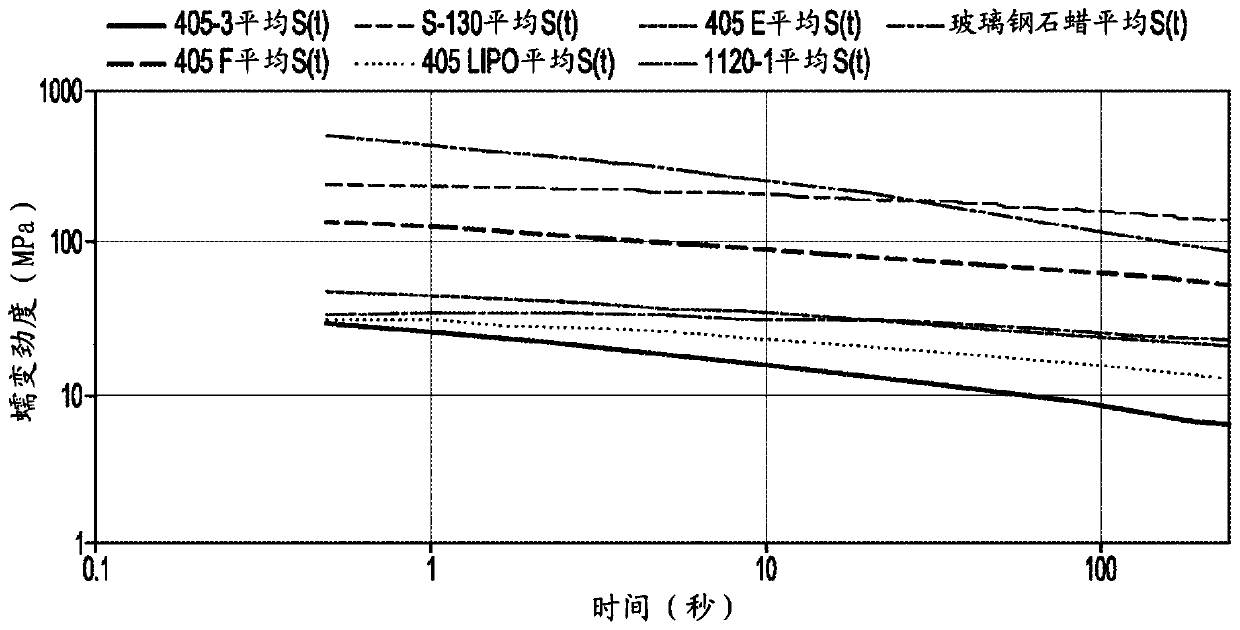

Embodiment 1

[0133]The following chemical transesterification method was performed to prepare samples 405-3, 405D, 405E, 405F, 1120-1 and 607-1 in the figure. All fatty acids (including dimers) or oils described in Table 2 were pre-melted and heated to 70°C before adding to the reaction vessel. The melted fatty acid or oil is then added to the reaction vessel and a nitrogen sparge is started to prevent oxidation of the product during the reaction. Then add the glycerin and turn on the mixer to mix the contents. Caustic catalyst (potassium hydroxide (KOH) or calcium hydroxide (Ca(OH) 2 )). Once all ingredients are added and mixed well, the temperature is raised to 200°C to 250°C. The reaction temperature was varied to determine the effect of reaction time on product properties. The reaction temperature is maintained until an acid number of 1.5 or less is reached. 0.2% acid (85% strength phosphoric acid) was added to neutralize the catalyst in slight excess. The mixture was cooled to 7...

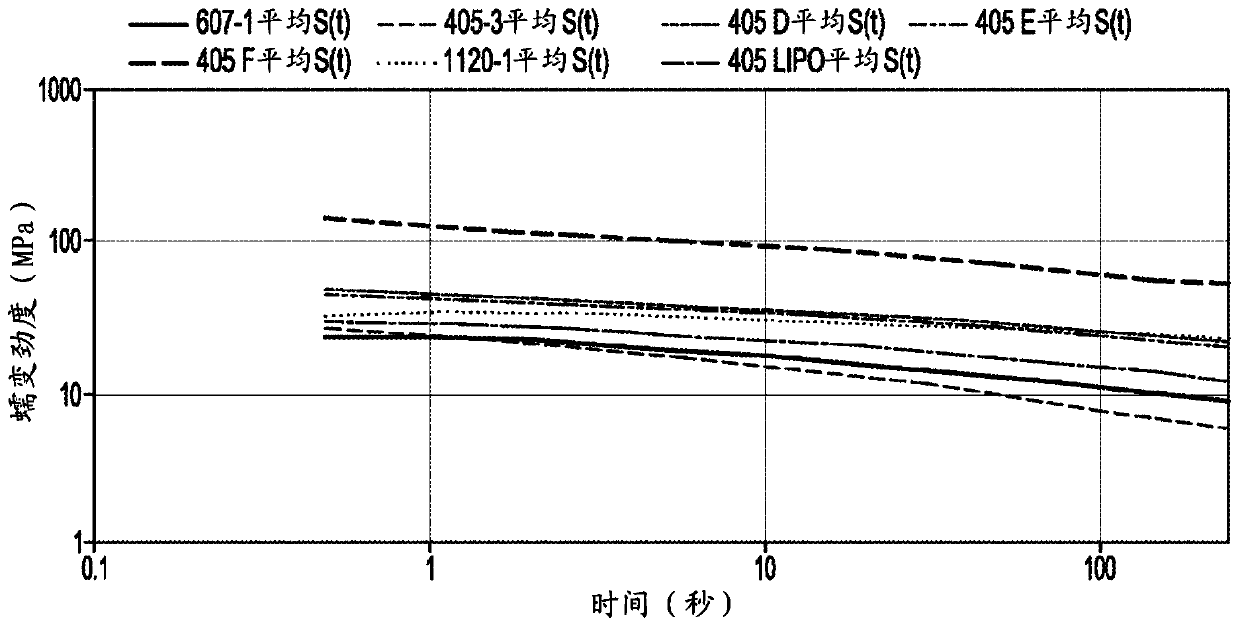

Embodiment 2

[0135] The following enzymatic transesterification method was performed to prepare sample 405Lipo. All fatty acids or oils described in Table 2 were pre-melted and heated to 70°C before adding to the reaction vessel. The melted fatty acid or oil is then added to the reaction vessel and a nitrogen sparge is started to prevent oxidation of the product during the reaction. Then add the glycerin and turn on the mixer to mix the contents. 2% of the enzyme catalyst, lipase Novozyme 435, was added to the reaction. As the reaction progressed, a vacuum of 50 Torr was applied to the sample to remove all water. A temperature of 70°C was maintained until an acid number of 1.5 or less was reached. Filter off the enzyme catalyst using a Buchner funnel and filter paper.

[0136] Table 2

[0137]

[0138] table 3

[0139]

[0140] Table 2 provides the formulations for each sample. With the exception of 405F, all samples in Table 2 had dimers present in the formulation and are...

Embodiment 3

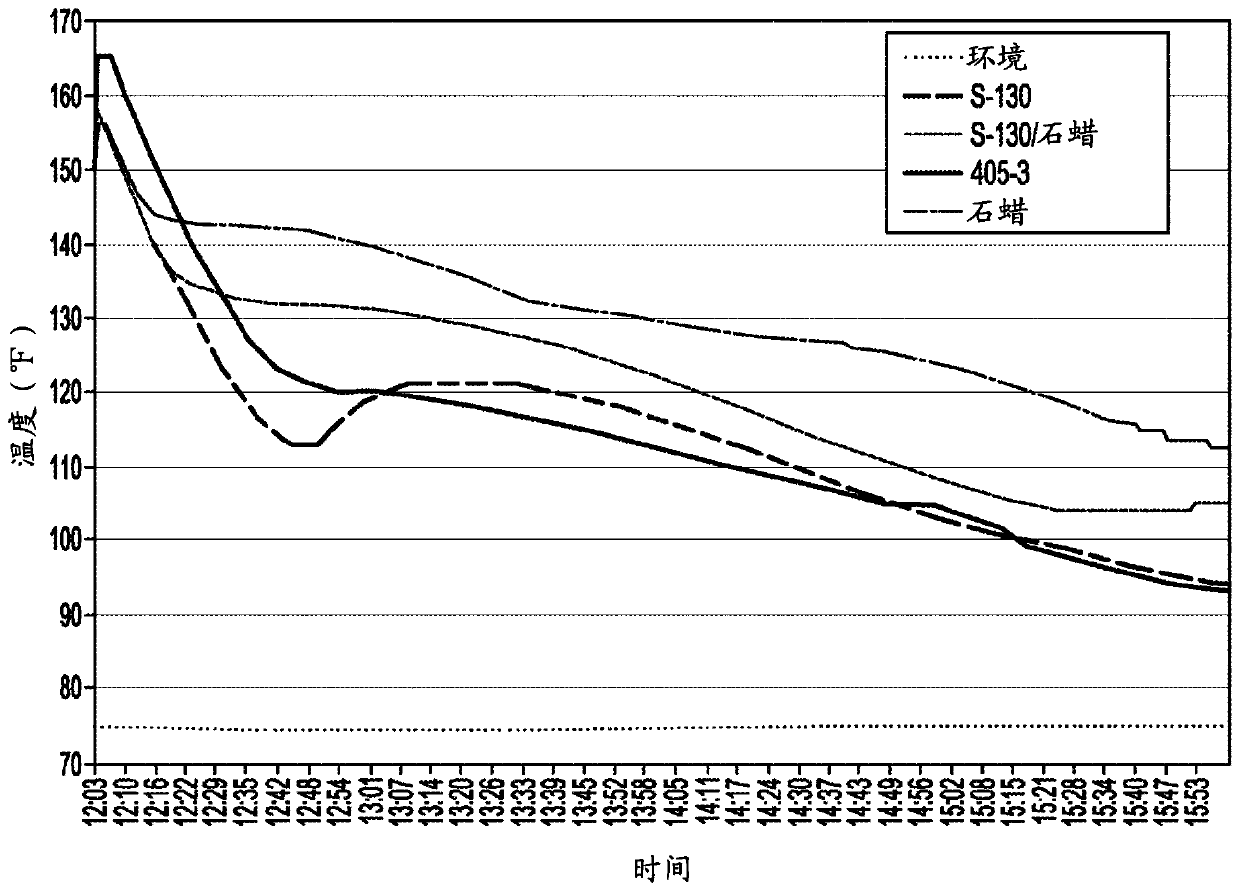

[0153] Several wax compositions were heated and cooled while monitoring their internal temperatures. The wax compositions tested were S-130 wax (conventional partially hydrogenated soy wax), conventional paraffin, a blend of S-130 and paraffin, and Example 405-3. Cooling is measured over a period of approximately six hours.

[0154] Such as image 3 As shown, conventional soy wax has a rapid initial cooling rate, but then shows a significant warming after about 45 minutes of cooling. Regular paraffin showed the slowest cooling rate. The blend of conventional soy wax and conventional paraffin wax showed a slow cooling rate, but also a cooling rate that flattened out over a period of 30 minutes to 3 hours. In contrast, Example 405-3 exhibited a rapid cooling rate with a rate comparable to that of the S-130 wax, but it did not undergo the ramp-up period exhibited by the S-130 wax.

[0155] The temperature spikes produced by conventional soy wax disrupt and adversely affect th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dropping point | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com