Blueberry preservative and preparation and application thereof

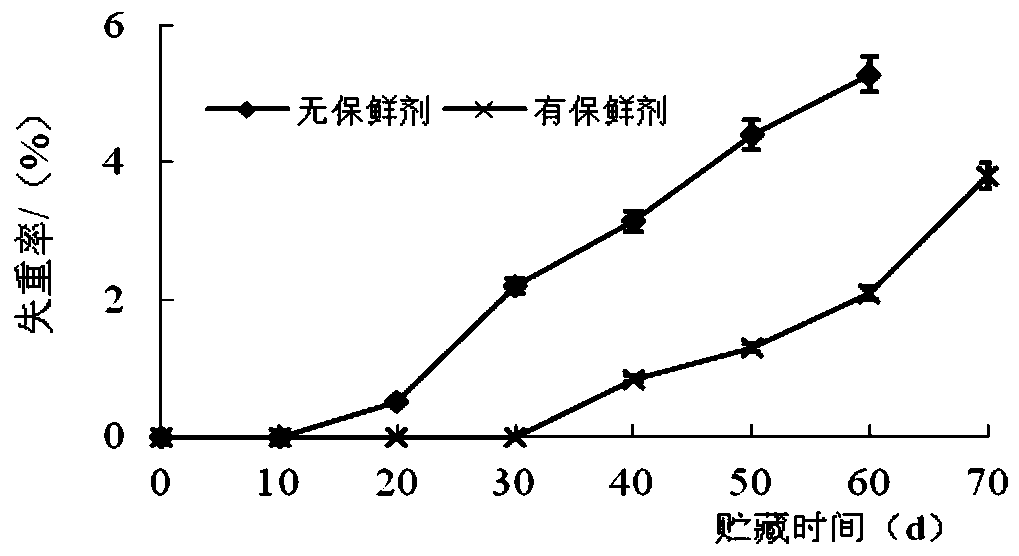

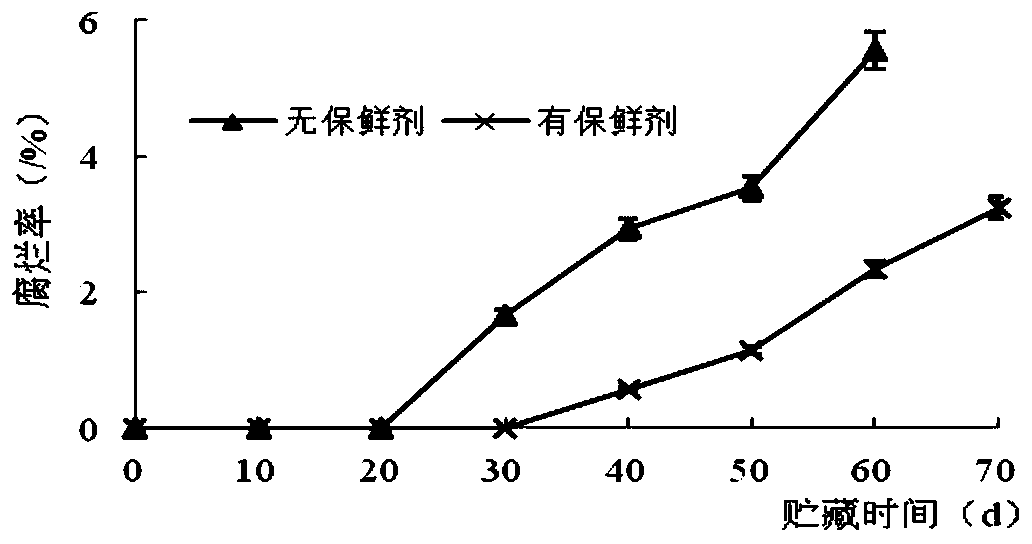

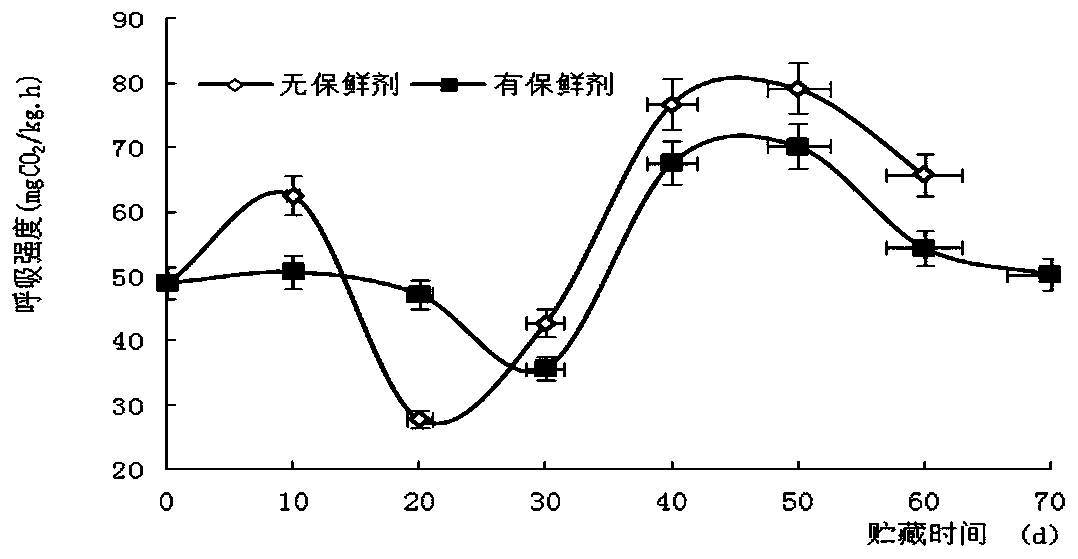

A preservative, blueberry technology, applied in application, fruit and vegetable preservation, food preservation and other directions, can solve the problems of blueberry quality decline, prolong blueberry preservation time and other problems, and achieve the effect of prolonging preservation period, prolonging preservation time and reducing transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a preparation method of the antistaling agent described in the above technical proposal, comprising the following steps: mixing the components with water, drying the obtained mixture, and obtaining the antistaling agent.

[0048] In the present invention, the mixing method preferably includes crushing and sieving the components in sequence to obtain crushed materials, and mixing the crushed materials with water to obtain a mixture. In the present invention, the crushed material is mixed with water to form granules, and the amount of water is preferably 1-4% of the total weight of the components of the blueberry preservative, and more preferably 4%. The mixture is made into granules and then dried. The particle size of the preservative is preferably 2.45-2.53 mm, more preferably 2.5 mm. In the present invention, the antistaling agent is made into granules, which is not only convenient for transportation and use, but also expands the contact area on...

Embodiment 1

[0054] Prepare the blueberry preservative, wherein the mass percent of each component is: ferrous chloride 10%, ferrous sulfate 8%, sodium carbonate 5%, sodium bicarbonate 15%, potassium permanganate 8%, ascorbic acid 3%, Sodium hypochlorite 2.5%, anhydrous calcium chloride 1.3%, zinc oxide 2%, sodium polyacrylate 0.2%, zeolite 45%.

[0055] Mix the above components evenly, crush them and sieve, add 4% water of the total weight of the above components and stir thoroughly to make particles with a diameter of about 2.5mm, and then dry at 110°C. Use air-permeable materials such as paper or cloth to pack the preservative into 5g packets. Then put the antistaling agent and the fruit into the package according to the amount of fruit weight 5.0Kg / 5g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com