A kind of preparation method of modified polymethylsilane

A polymethylsilane modification technology, applied in the field of polymethylsilane modification, can solve problems such as introduction barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

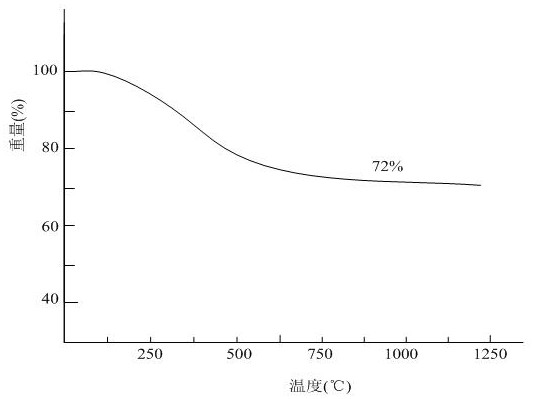

Embodiment 1

[0026] 19 L of dibutyl ether, 15.0 kg of methyl dichlorosilane, 2.943 kg of chloromethyl methyl dichlorosilane and 0.7 kg of 1,1-dichlorosilyl cyclobutane were added to the feeding tank, and they were mixed for later use.

[0027] A 100L reaction kettle was evacuated and replaced with nitrogen for 1 to 3 times. Under nitrogen protection, 20L of dibutyl ether was added to the reaction kettle, and 7.2kg of fresh sodium was added. The water was removed by heating the built-in 110°C oil bath in the reactor until the sodium melted, and stirring and refluxing for 1 hour to remove the entrained water in the butyl ether. The temperature in the reaction kettle is 106-115 DEG C, and the sodium sand is formed by stirring at a rotating speed of 350 RPM.

[0028] Then slowly add the above mixture in the feeding tank to the reaction kettle through the dropping funnel for reaction, while controlling the temperature of the mixture in the reaction kettle at 106-115 °C, the addition is complet...

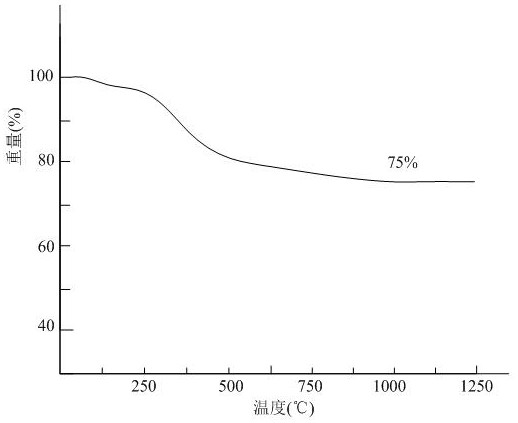

Embodiment 2

[0036] 19L of dibutyl ether, 14kg of methyldichlorosilane, 3.75kg of chloromethylmethyldichlorosilane, and 1.08kg of 1,1-dichlorosilylcyclobutane were added into the feeding tank, and they were mixed for later use.

[0037] 100L reaction kettle, evacuated and replaced with nitrogen for 1-3 times. Under nitrogen protection, 20 L of dibutyl ether was added to the reaction kettle, 7.2 kg of fresh sodium was added, and the sodium was melted by heating the system in an oil bath at 110° C. in the reaction kettle, and stirred and refluxed for 1 hour to remove the water entrained in the butyl ether. The temperature in the reaction kettle is 106-115 DEG C, and the sodium sand is formed by stirring at a rotating speed of 350 RPM.

[0038] Then slowly add the above mixture in the feeding tank to the reaction kettle through the dropping funnel for reaction, while controlling the temperature of the mixture in the reaction kettle at 106 ~ 115 ℃, the dropwise addition is completed in about 2...

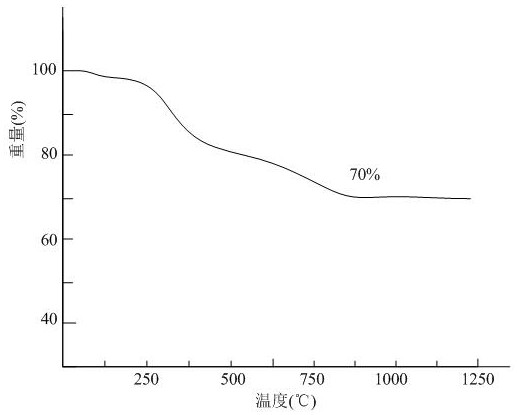

Embodiment 3

[0046] 19L of dibutyl ether, 15.8kg of methyldichlorosilane, 2kg of chloromethylmethyldichlorosilane, and 0.43kg of 1,1-dichlorosilylcyclobutane were added into the feeding tank, and they were mixed for later use.

[0047] A 100L reaction kettle was evacuated and replaced with nitrogen for 1 to 3 times. Under nitrogen protection, 20 L of dibutyl ether was added to the reaction kettle, 7.2 kg of fresh sodium was added, the sodium was melted by the 110° C. oil bath heating system in the reaction kettle, and the water entrained in the butyl ether was removed by stirring and refluxing for 1 hour. The temperature in the reaction kettle is 106-115 DEG C, and the sodium sand is formed by stirring at a rotating speed of 350 RPM.

[0048] Then slowly add the above mixture in the feeding tank to the reaction kettle through the dropping funnel for reaction, while controlling the temperature of the mixture in the reaction kettle at 106 ~ 115 ℃, the dropwise addition is completed in about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com