Electroplating solution for diamond cutting line and preparation method of electroplating solution

A diamond cutting wire and solution technology, applied in the field of electroplating, can solve the problems of loss of cutting ability, easy falling off of diamond particles, pinholes in the coating, etc., and achieve the effect of increasing the anode current density, promoting normal dissolution, and improving the toughness of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

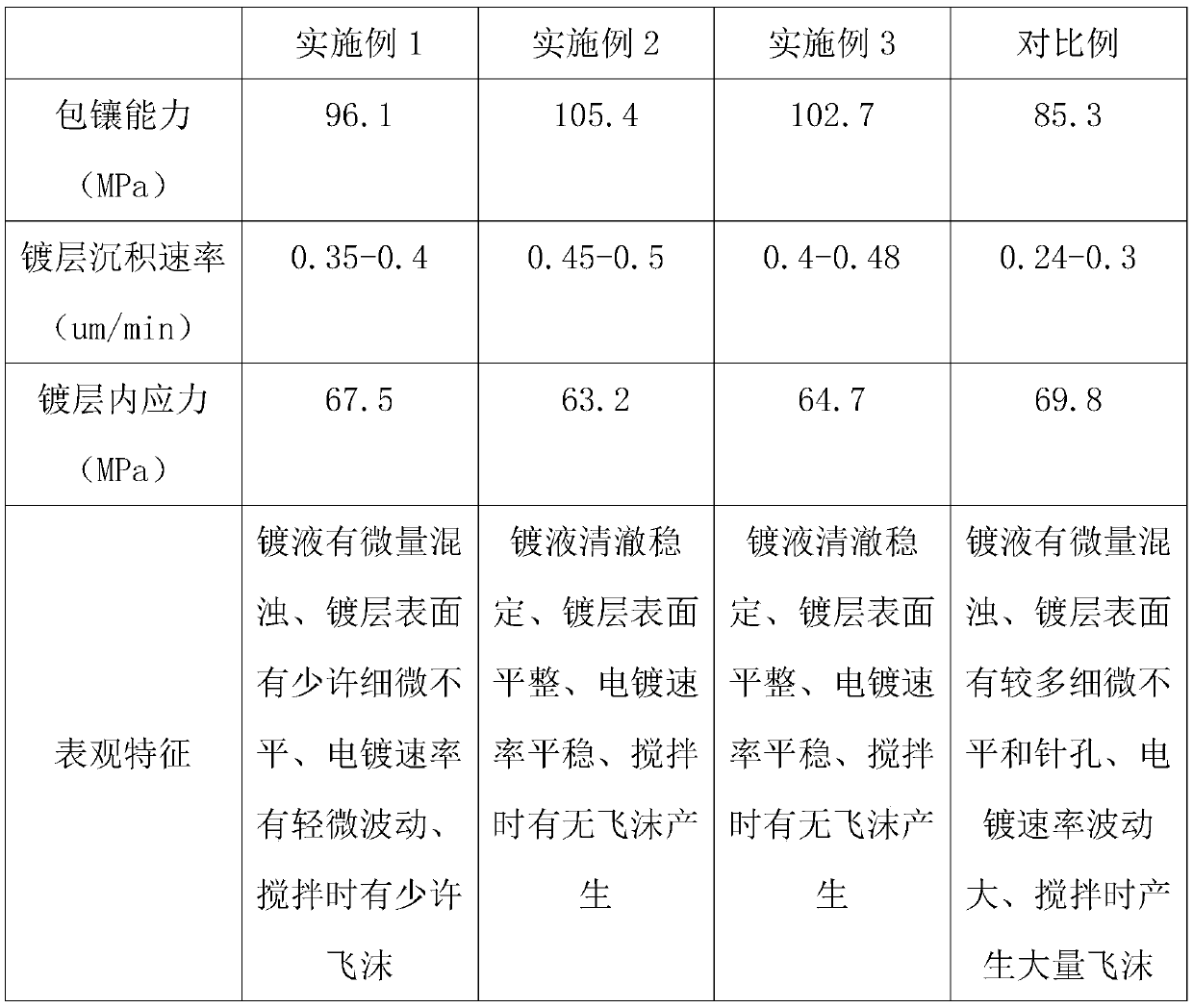

Examples

Embodiment 1

[0029] The invention provides an electroplating solution for a diamond cutting wire, comprising the following concentration of solutes: main salt 300g / L, conductive salt 20g / L, complexing agent 3ml / L, stress reliever 8ml / L, electroplating stabilizer 25ml / L L, coating refiner 8ml / L, anode activator 5ml / L, diamond powder 10g / L, other additives 35ml / L, appropriate amount of buffer, and the solvent used for the solute is water;

[0030] The main salt is nickel sulfamate;

[0031] The conductive salt is any one of NaCl or KCl, which can greatly increase the conductivity of the solution, and will not complexate the discharge metal ions;

[0032] Complexing agent is K 4 P 2 o 7 or Na 4 P 2 o 7 Any one of them can improve the dispersing ability and covering ability of the plating solution;

[0033] The stress reliever is coumarin, which can reduce the internal stress of the coating and improve the toughness of the coating;

[0034] Buffer is H 3 BO 3 or Na 2 HPO 4 Any one ...

Embodiment 2

[0046] The invention provides a kind of electroplating solution for diamond cutting wire, comprising the following concentration of solute: main salt 400g / L, conductive salt 25g / L, complexing agent 4ml / L, stress reliever 10ml / L, electroplating stabilizer 28ml / L L, coating refiner 12ml / L, anode activator 8ml / L, diamond micropowder 13g / L, other additives 40ml / L, buffering agent amount, and the used solvent of this solute is water;

[0047] The main salt is nickel sulfamate;

[0048] The conductive salt is any one of NaCl or KCl, which can greatly increase the conductivity of the solution, and will not complexate the discharge metal ions;

[0049] Complexing agent is K 4 P 2 o 7 or Na 4 P 2 o 7 Any one of them can improve the dispersing ability and covering ability of the plating solution;

[0050] The stress reliever is coumarin, which can reduce the internal stress of the coating and improve the toughness of the coating;

[0051] Buffer is H 3 BO 3 or Na 2 HPO 4 Any...

Embodiment 3

[0063] The invention provides a kind of electroplating solution for diamond cutting wire, comprising the following concentration of solute: main salt 500g / L, conductive salt 30g / L, complexing agent 5ml / L, stress reliever 12ml / L, electroplating stabilizer 30ml / L L, coating refiner 15ml / L, anode activator 10ml / L, diamond powder 15g / L, other additives 45ml / L, appropriate amount of buffer, and the solvent used for the solute is water;

[0064] The main salt is nickel sulfamate;

[0065] The conductive salt is any one of NaCl or KCl, which can greatly increase the conductivity of the solution, and will not complexate the discharge metal ions;

[0066] Complexing agent is K 4 P 2 o 7 or Na 4 P 2 o 7 Any one of them can improve the dispersing ability and covering ability of the plating solution;

[0067] The stress reliever is coumarin, which can reduce the internal stress of the coating and improve the toughness of the coating;

[0068] Buffer is H 3 BO 3 or Na 2 HPO 4 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com