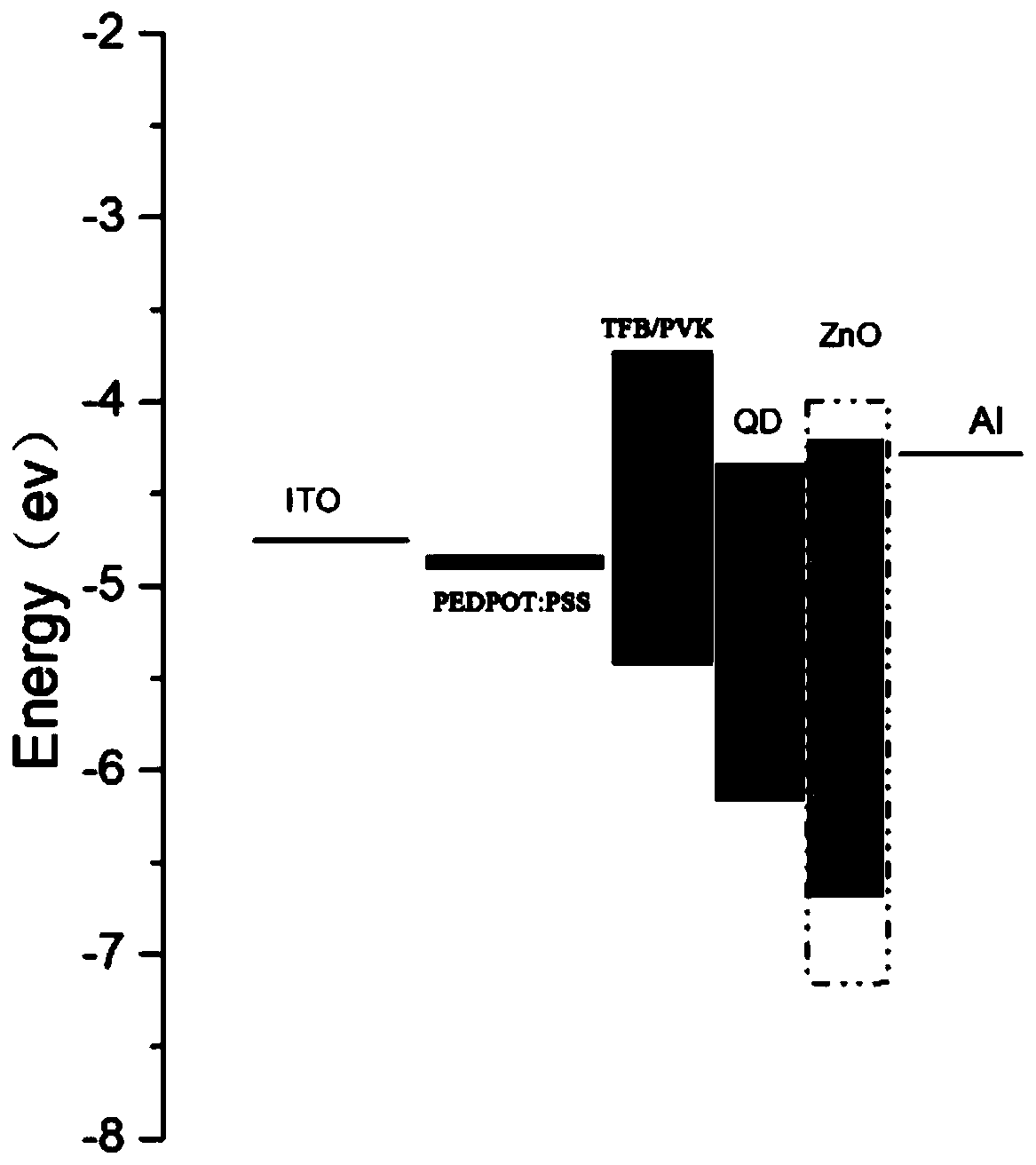

Image display device, quantum dot light-emitting diode and manufacturing method thereof

A technology of quantum dot light emission and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as large leakage current of devices and changes in charge mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] 1. Raw material preparation

[0082] 1) NaHCO 3 Solution and NaBH 4 Preparation of the solution:

[0083] Take 20mg of NaHCO 3 Disperse in 4ml ethyl acetate and stir evenly to form a uniform and transparent solution for later use;

[0084] Take 20mg of NaBH 4 Disperse in 4ml of ethanol and stir to form a uniform and transparent solution for later use.

[0085] 2) NaHCO 3 The solution is mixed with CdSe / ZnS red quantum dots, NaBH 4 The solution is mixed with ZnO nanoparticle ink:

[0086] Take 1ml of prepared NaHCO 3 The solution and 3ml of CdSe / ZnS red quantum dot ink (concentration: 30mg / ml, ink reagent: octane) are uniformly mixed at room temperature to form a homogeneous solution (quantum dot ink) and then used;

[0087] Take 1ml of NaBH with a good concentration 4 The solution and 3ml of ZnO ink (concentration: 40mg / ml, ink reagent: ethanol) are uniformly mixed at room temperature to form a uniform solution (electronic transmission ink) for use.

[0088] 3) Hole transport layer...

Embodiment 2

[0103] 1. Raw material preparation

[0104] 1) NaHSO 3 Solution and NaBH 4 Preparation of the solution:

[0105] Take 20mg of NaHSO 3 Disperse in 4ml ethyl acetate and stir evenly to form a uniform and transparent solution for later use;

[0106] Take 20mg of NaBH 4 Disperse in 4ml of ethanol and stir to form a uniform and transparent solution for later use.

[0107] 2) NaHSO 3 The solution is mixed with CdSe / ZnS red quantum dots, NaBH 4 The solution is mixed with ZnO nanoparticle ink:

[0108] Take 1ml of prepared NaHSO 3 The solution and 3ml of CdSe / ZnS red quantum dot ink (concentration: 30mg / ml, ink reagent: octane) are uniformly mixed at room temperature to form a homogeneous solution (quantum dot ink) and then used;

[0109] Take 1ml of NaBH with a good concentration 4 The solution and 3ml of ZnO ink (concentration: 40mg / ml, ink reagent: ethanol) are uniformly mixed at room temperature to form a uniform solution (electronic transmission ink) for use.

[0110] 3) Hole transport layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com