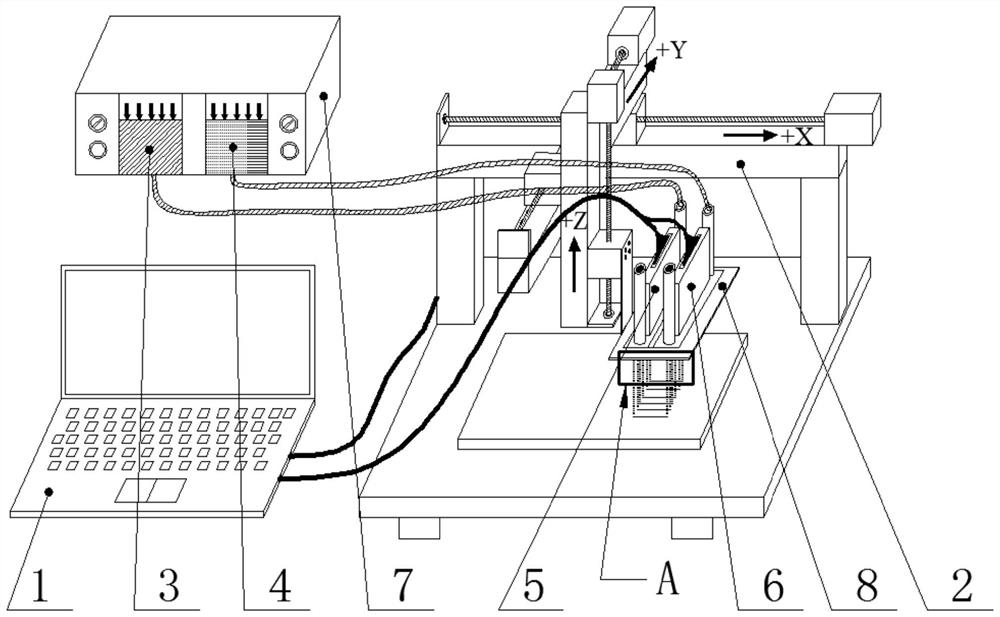

Device for ink-jet printing gel microsphere, and printing method

A gel microsphere, inkjet printing technology, applied in coating devices, manufacturing auxiliary devices, additive manufacturing, etc., can solve the problems of low manufacturing efficiency, uneven size, complex process, etc., and achieve improved efficiency and uniform size. , the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

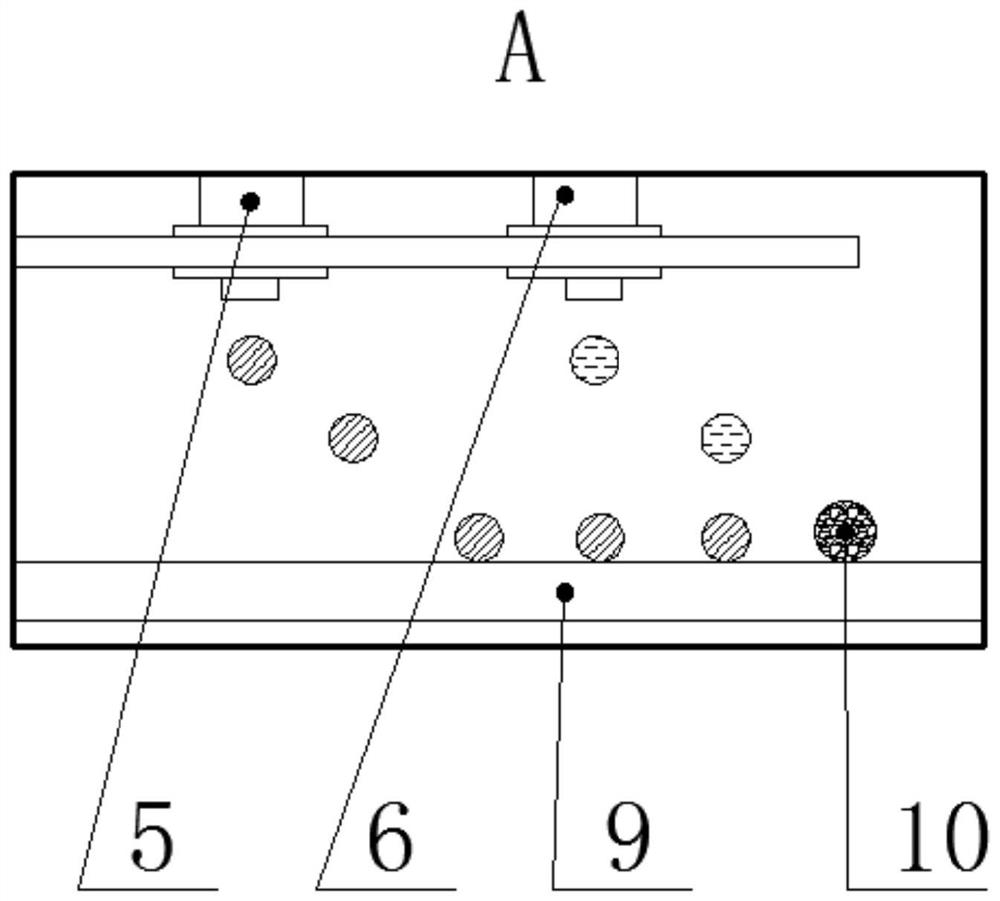

Method used

Image

Examples

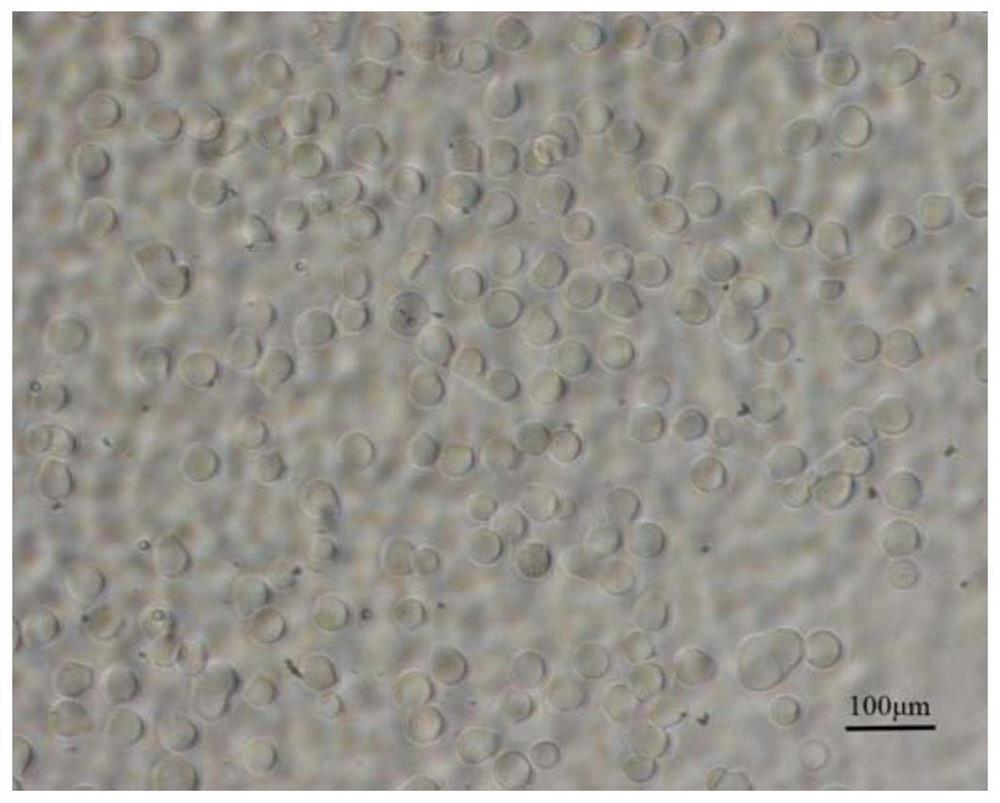

Embodiment 1

[0048] Two-component solution is respectively 4% (w / v) sodium alginate DPBS aqueous solution and 4% (w / v) calcium chloride deionized aqueous solution, the preparation method of two kinds of solutions is:

[0049] At room temperature, 16 g of sodium alginate A0682 powder was dissolved in 400 ml of DPBS aqueous solution, and magnetically stirred at 400 r / min for 12 hours to prepare a sodium alginate DPBS aqueous solution with a concentration of 4% (w / v). Put the prepared sodium alginate solution into a vertical pressure steam sterilizer and heat it to 125°C for 25 minutes. After the solution was cooled to room temperature, it was filtered through a filter membrane with a pore size of 1 μm.

[0050] At room temperature, 16g of calcium chloride powder was dissolved in 400ml of deionized water, and magnetically stirred at a speed of 200r / min for 30min. Then add 0.01% (v / v) fluorine-containing nonionic surfactant to the calcium chloride aqueous solution FC~4430, magnetic stirring...

Embodiment 2

[0056] Two-component solutions are respectively 3% (w / v) sodium alginate DPBS aqueous solution and 2% (w / v) calcium chloride deionized aqueous solution, and the preparation method of two kinds of solutions is:

[0057] At room temperature, 12 g of sodium alginate A0682 powder was dissolved in 400 ml of DPBS aqueous solution, and magnetically stirred at 400 r / min for 8 hours to prepare a sodium alginate DPBS aqueous solution with a concentration of 3% (w / v). Put the prepared sodium alginate solution into a vertical pressure steam sterilizer and heat it to 125°C for 25 minutes. After the solution was cooled to room temperature, it was filtered through a filter membrane with a pore size of 1 μm.

[0058] At room temperature, 8 g of calcium chloride powder was dissolved in 400 ml of deionized water, and magnetically stirred at a speed of 200 r / min for 30 min. Then add 0.01% (v / v) fluorine-containing nonionic surfactant to the calcium chloride aqueous solution FC~4430, magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com