Positive electrode and preparation method and application thereof

A positive electrode and positive active material technology, applied in the field of positive electrode and its preparation, can solve the problems of increased battery internal resistance, increased heat production, etc., and achieve the effect of reducing internal resistance, reducing heat production, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

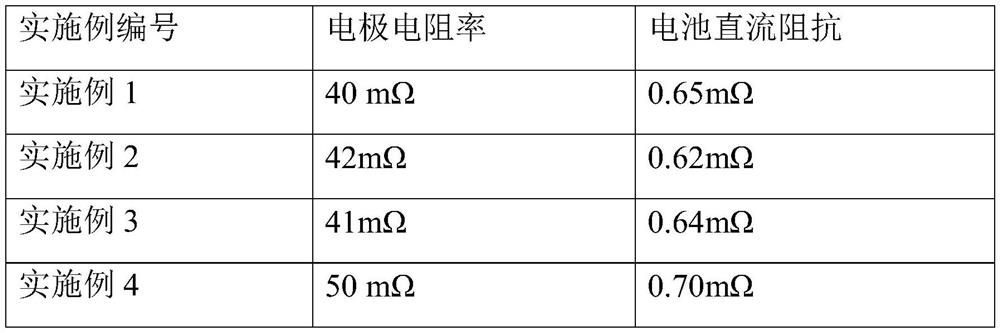

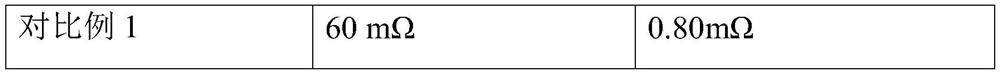

Examples

preparation example Construction

[0037] The second aspect of the present invention provides a method for preparing a positive electrode as described above, wherein the method includes the following steps:

[0038] (1) The positive electrode active material, the first conductive agent, the optional second conductive agent and the binder are according to the weight of (85-97):(0.5-5):(0-5):(1-5) Mix evenly in the nitrogen methyl pyrrolidone solvent to prepare at least two coating slurries containing different total conductive agent contents;

[0039] (2) Mix the first conductive agent, the optional second conductive agent and the binder in the nitrogen methyl pyrrolidone solvent according to the weight ratio of (10-95):(0-70):(3-15) , prepared into a conductive layer slurry;

[0040] (3) Alternately coating the coating slurry and the conductive layer slurry on both sides of the current collector, then drying and hot rolling to obtain the positive electrode;

[0041] Wherein, along the direction away from the cu...

Embodiment 1

[0061] (1) Li(Ni 0.65 mn 0.35 )O 2 , conductive carbon black, carbon nanotubes and polyvinylidene fluoride are uniformly mixed in nitrogen methyl pyrrolidone solvent according to the weight ratio of 90:2.5:2.5:5 to obtain coating slurry 1, wherein, in coating slurry 1 , Li(Ni 0.65 mn 0.35 )O 2 , the weight ratio of the total weight of conductive carbon black, carbon nanotubes and polyvinylidene fluoride to nitrogen methyl pyrrolidone solvent is 1:0.65;

[0062] (2) Li(Ni 0.65 mn 0.35 )O 2 , conductive carbon black, carbon nanotubes and polyvinylidene fluoride are uniformly mixed in nitrogen methyl pyrrolidone solvent according to the weight ratio of 92:2.5:2:3.5 to obtain coating slurry 2, wherein, in coating slurry 2 , Li(Ni 0.65 mn 0.35 )O 2 , the weight ratio of the total weight of conductive carbon black, carbon nanotubes and polyvinylidene fluoride to nitrogen methylpyrrolidone (NMP) solvent is 1:0.65;

[0063] (3) Conductive carbon black, carbon nanotubes and...

Embodiment 2

[0070] (1) Li(Ni 0.7 mn 0.3 )O 2 , conductive carbon black, carbon nanotubes and polyvinylidene fluoride are uniformly mixed in nitrogen methyl pyrrolidone solvent according to the weight ratio of 95.5:1.5:1.2:1.8 to obtain coating slurry 1, wherein, in coating slurry 1 , Li(Ni 0.7 mn 0.3 )O 2 , the weight ratio of the total weight of conductive carbon black, carbon nanotubes and polyvinylidene fluoride to nitrogen methyl pyrrolidone solvent is 1:0.35;

[0071] (2) Li(Ni 0.7 mn 0.3 )O 2 , conductive carbon black, carbon nanotubes and polyvinylidene fluoride are uniformly mixed in nitrogen methyl pyrrolidone solvent according to the weight ratio of 96.5:1.3:1:1.2 to obtain coating slurry 2, wherein, in coating slurry 2 , Li(Ni 0.7 mn 0.3 )O 2 , the weight ratio of the total weight of conductive carbon black, carbon nanotubes and polyvinylidene fluoride to nitrogen methylpyrrolidone (NMP) solvent is 1:0.35;

[0072] (3) Conductive carbon black, carbon nanotubes and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com