P-type organic semiconductor material, preparation method and display panel

An organic semiconductor and organic technology, applied in the field of P-type organic semiconductor materials, preparation methods and display panels, can solve the problems of high cost and difficult synthesis, and achieve low cost, improved hole mobility, and high degree of planarization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

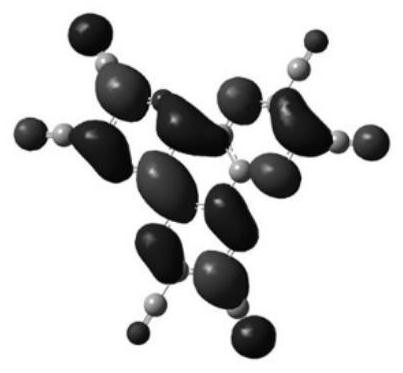

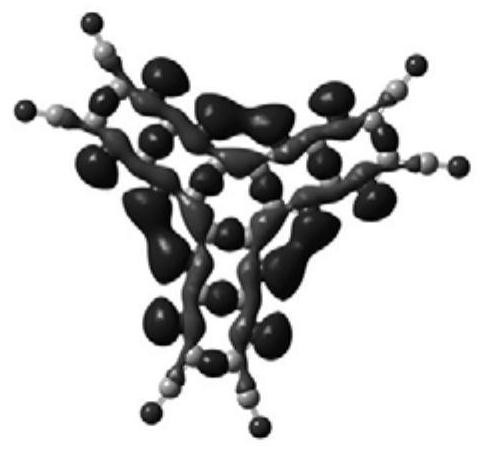

Image

Examples

preparation example Construction

[0048] The present application also provides a method for preparing a P-type organic semiconductor material, the preparation method comprising the following steps: making a first reactant containing a diketone undergo a cyclization reaction with a second reactant containing a diamine to generate the P type organic semiconductor materials;

[0049] Wherein, the P-type organic semiconductor material has the following

[0050] The molecular structure represented, wherein, X is a carbon atom or a nitrogen atom; the R7, R8, R8, R10, R11, R12 are selected from the first substituent group;

[0051] When said R1 and said R2 are ring-opened, said R1 and said R2 are selected from said first substituent group,

[0052] When said R1 and said R2 form a ring, the structural formula after said R1 and said R2 form a ring is selected from A kind of, said group m1, m2, m3 and m4 are selected from the second substituent group;

[0053] When said R3 and said R4 are ring-opened, said R3 and ...

Embodiment 1

[0071] Cyclohexanone (0.98g, 10mmol), 5,6-diaminopiperidine-2,3-dicyano (12.01g, 75mmol) and catalyst, specifically, the catalyst can be added to the reaction vessel using acetic acid (100mL) middle. Under the protection of argon, the reaction was heated for 2h. The obtained mixture is hot filtered, washed and dried, and the solvent for washing may be hot acetic acid. The target product 1 was obtained by separation and purification. The method of separation and purification can be to use 200-300 mesh silica gel column chromatography on the crude product, the eluent is dichloromethane (DCM) decolorization, rotary evaporation, and vacuum drying to obtain a dark brown solid, and then sublimate to obtain a light yellow solid , which is the target product 1

[0072] The mass of the obtained target product 1 was 2.68 g, and the yield was 81%.

[0073] HRMS[M+H]+calcd.for C24N18:540.0553;found:540.0534.

[0074] The chemical equation for the reaction is:

[0075]

Embodiment 2

[0077] (0.98 g, 10 mmol), 4,5-diamino-3,6-difluorophthalonitrile (14.55 g, 75 mmol) and acetic acid (100 mL) were added to the reaction vessel. Under the protection of argon, the reaction was heated for 2h. The obtained mixture is hot filtered, washed and dried, and the solvent for washing may be hot acetic acid. The target product 2 was obtained by separation and purification. The method of separation and purification can be to use 200-300 mesh silica gel column chromatography on the crude product, the eluent is dichloromethane (DCM) decolorization, rotary evaporation, and vacuum drying to obtain a dark brown solid, and then sublimate to obtain a light yellow solid , which is the target product 2 The mass of the obtained target product 2 was 2.63 g, and the yield was 82%.

[0078] HRMS[M+H]+calcd.for C30F6N12:642.0273;found:642.0277.

[0079] The chemical equation for the reaction is:

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com