Efficient clothes cleaning agent and preparation method thereof

A cleaning agent and clothing technology, applied in the field of cleaning agents, can solve the problems of blood stains, oil stains that are difficult to remove, poor decontamination ability, poor new effect, etc., to achieve improved decontamination ability and efficiency, good degreasing power, anti-corrosion Good hard water ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

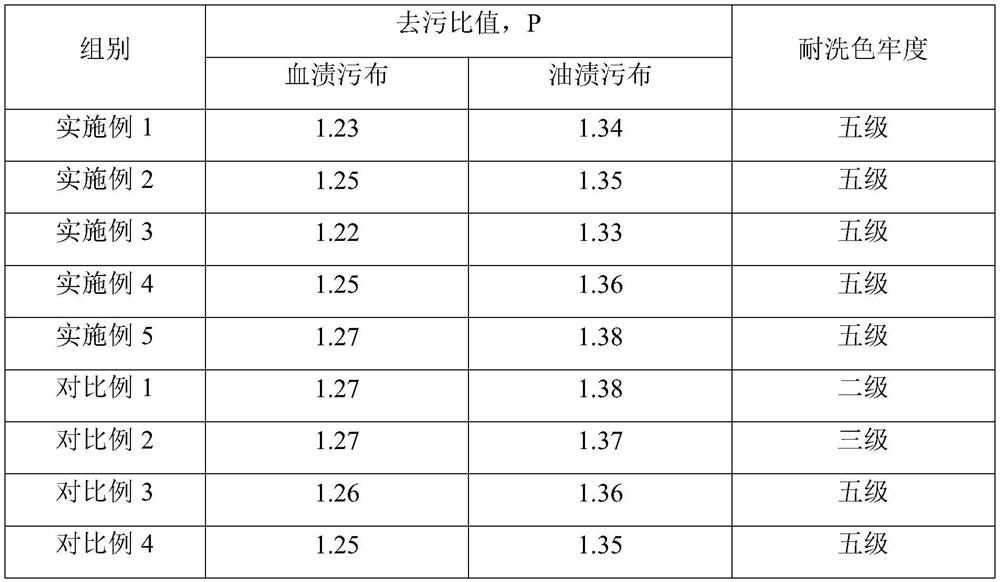

Examples

Embodiment 1

[0021] A high-efficiency laundry detergent, comprising the following components in parts by mass: 15 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 10 parts of lauryl amidopropyl betaine, 4 parts of coconut oil fatty acid diethanolamide, fluorocarbon surfactant 1 part, 0.1 part of imidazole modified hydroxyethyl cellulose, 0.1 part of protease, 5 parts of enzyme stabilizer, 0.1 part of complexing agent and 40 parts of water. The enzyme stabilizer includes calcium ammonium citrate with a mass ratio of 1:1:1, alkyl glucoside APG0810 with 8-10 carbon atoms and APG1214 with 12-14 carbon atoms. Calcium ammonium citrate is obtained by compounding ammonium citrate and calcium citrate at a molar ratio of 24:1. The complexing agent includes methyl glycine diacetic acid and L-560 organic complexing agent with a mass ratio of 0.1:1.

[0022] Its preparation method comprises the following steps:

[0023] 1) Add 40-50% water into the chemical tank, heat to 50-60°C, then add...

Embodiment 2

[0027] Different from Example 1: the high-efficiency laundry detergent of the present embodiment includes the composition of the following mass parts: 20 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 20 parts of lauryl amidopropyl betaine, coconut oil fatty acid diethanol 8 parts of amide, 5 parts of fluorocarbon surfactant, 2 parts of imidazole modified hydroxyethyl cellulose, 0.5 parts of protease, 10 parts of enzyme stabilizer, 1 part of complexing agent and 60 parts of water. The enzyme stabilizer includes calcium ammonium citrate with a mass ratio of 2:1:2, alkyl glucoside APG0810 with 8-10 carbon atoms and APG1214 with 12-14 carbon atoms. The complexing agent includes methyl glycine diacetic acid and L-560 organic complexing agent with a mass ratio of 0.5:1.

[0028] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0030] Different from Example 1: the high-efficiency laundry detergent of the present embodiment comprises the composition of following mass fractions: 17 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 12 parts of lauryl amidopropyl betaine, coconut oil fatty acid diethanol 5 parts of amide, 2 parts of fluorocarbon surfactant, 0.5 part of imidazole modified hydroxyethyl cellulose, 0.2 part of protease, 6 parts of enzyme stabilizer, 0.3 part of complexing agent and 45 parts of water. The enzyme stabilizer includes calcium ammonium citrate with a mass ratio of 1:1:2, alkyl glucoside APG0810 with 8-10 carbon atoms and APG1214 with 12-14 carbon atoms. The complexing agent includes methyl glycine diacetic acid and L-560 organic complexing agent with a mass ratio of 0.8:1.

[0031] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com