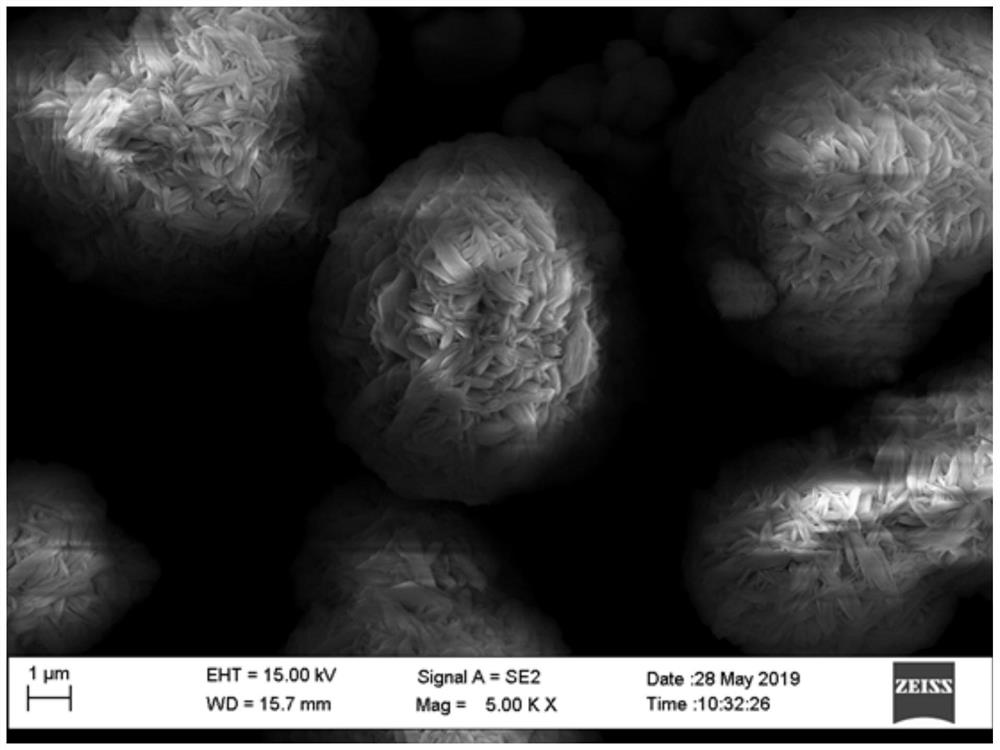

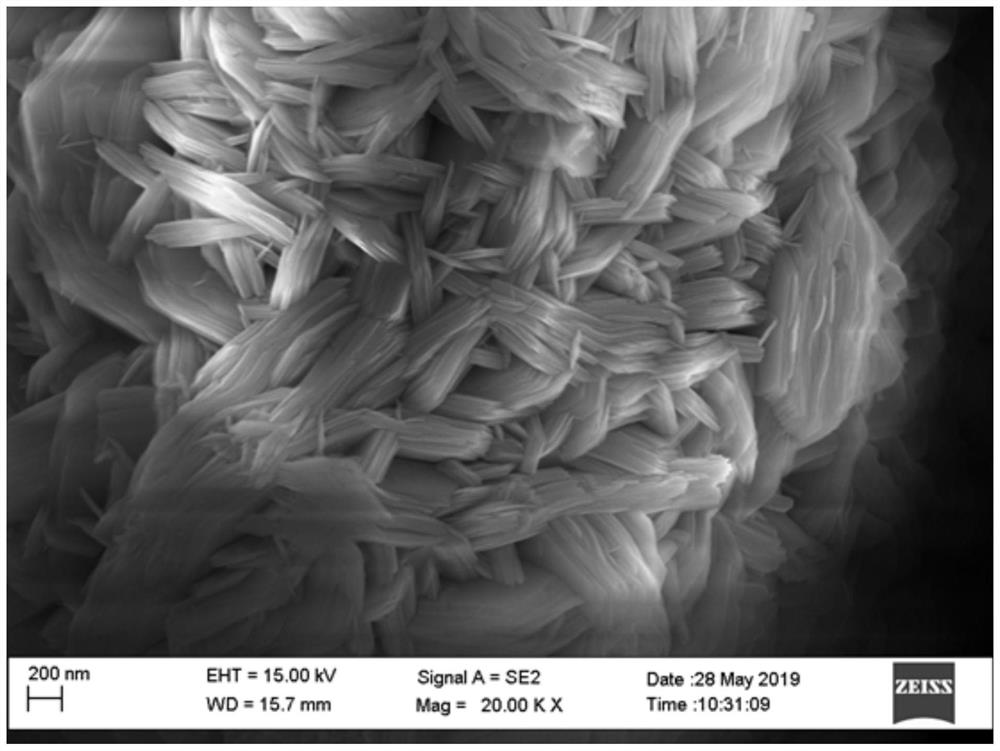

Preparation method of nickel-cobalt-manganese precursor with laminated and embedded stacked secondary particles

A technology of secondary particles, nickel-cobalt-manganese, applied in the direction of secondary batteries, chemical instruments and methods, nickel compounds, etc., can solve the problems of unsmooth internal structure, unfavorable operation of lithium intercalation and delithiation, etc., to achieve complete reaction, Lithium intercalation and delithiation are smooth and the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The invention discloses a method for preparing a nickel-cobalt-manganese precursor of sheet-like laminated embedded stacked secondary particles, which comprises the following steps:

[0039] Mixing stage: make nickel salt, cobalt salt, and manganese salt into a 1.5mol / L mixed solution according to the molar ratio of the metal amount Ni:Co:Mn=8:1:1, prepare 32% sodium hydroxide solution, and prepare 25% ammonia water; pour 60% of the volume of the reaction kettle into the bottom liquid, the bottom liquid contains 3% ammonia, the pH is adjusted to 11.80±0.20, the temperature is 55°C, and the stirring speed is 300rpm.

[0040]Precipitation stage: set the speed at 900rpm, use the metering pump to pump three kinds of solutions into the reaction kettle at the same time, fix the flow rate of nickel, cobalt, manganese mixed solution and ammonia water flow, the pH is automatically adjusted online, the reaction temperature is controlled at 55 ° C, and the pH value is 11.80 ±0.20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com