Preparation method of perovskite quantum dots and perovskite quantum dots

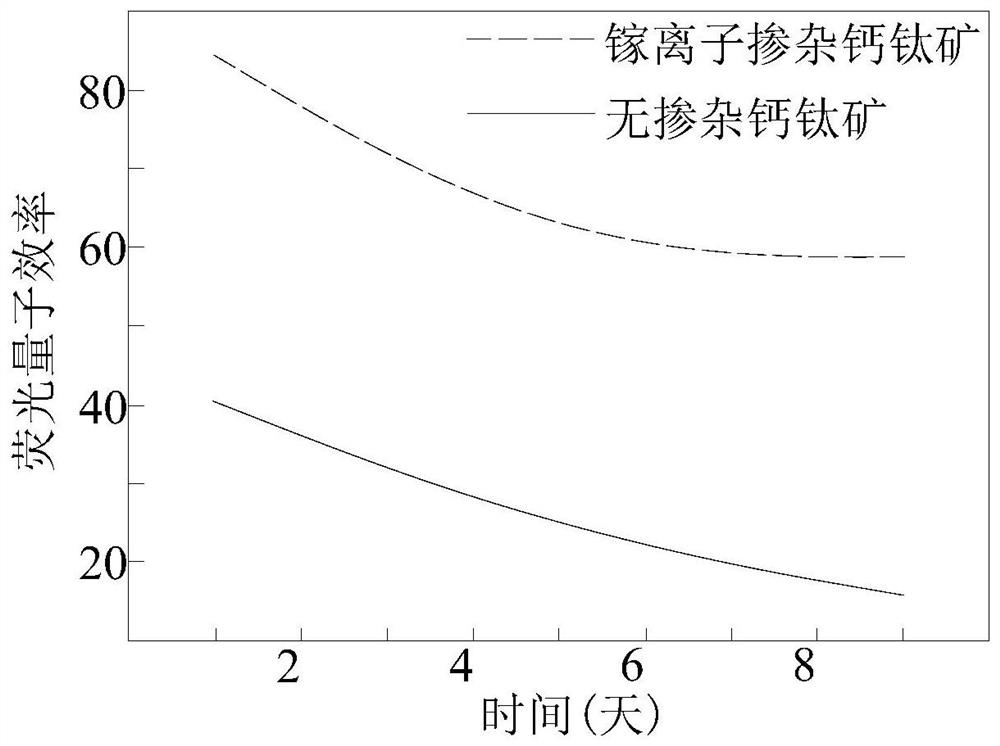

A quantum dot and perovskite technology, applied in the field of display, can solve the problems of limited practical application, decrease of fluorescence quantum efficiency, high surface defect state density, etc., to increase free carrier concentration, improve efficiency and stability, passivation The effect of surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0043] Embodiments of the present invention provide a method for preparing perovskite quantum dots, comprising the following steps:

[0044] A) Stir the mixture of lead halide-based precursor, cesium-based precursor and metal salt containing gallium ions to form gallium ion-doped perovskite quantum dots, wherein the doping of gallium ions in the perovskite quantum dots The impurity ratio is less than or equal to 5%.

[0045] In the process of preparing perovskite quantum dots, metal salts containing gallium ions (such as gallium nitrate, gallium chloride, gallium bromide, gallium iodide, etc.) Precursor reaction, the preparation of perovskite quantum dots (CsPbCl 3 / CsPbCl x Br 3-x / CsPbBr 3 / CsPbBr x I 3-x / CsPbI 3 ), the N-type doping brought by trivalent metal gallium ions can increase the free carrier concentration of perovskite quantum dots and passivate the defects on the perovskite surface, thereby improving the fluorescence quantum of the corresponding perovskit...

Embodiment 1

[0086] In this embodiment, perovskite quantum dots are prepared by hot injection method, as follows:

[0087] Preparation of cesium oleate precursor: add 0.1mol or A mol cesium carbonate to 15ml or more of octadecene, vacuumize, heat up to 100-120°C, discharge oxygen and water vapor, add 1.2ml or more of oil Acid, until the solution is completely free of bubbles, it takes about one hour, then stop vacuuming, protect with nitrogen, and then heat up to 150°C-160°C, preferably 150°C or 160°C, to form cesium oleate precursor, oleic acid The cesium precursor concentration is less than or equal to 1mol / L, heated and stirred at constant temperature.

[0088] Preparation of lead halide precursor containing gallium ions: add 0.1mmol or B mmol lead halide, C mmol gallium nitrate or corresponding gallium halide to octadecene greater than or equal to 5ml, where B=0.1-0.3, C / B =5%-80%, then vacuumize, heat up to 100-120°C, discharge oxygen and water vapor, inject oleic acid greater than o...

Embodiment 2

[0091] In this embodiment, the perovskite quantum dots are prepared by the ligand exchange method, as follows:

[0092] Prepare the precursor: disperse cesium halide and lead halide in equal molar ratios in DMSO or DMF solution, then add gallium nitrate or the corresponding gallium halide in a certain molar ratio (the molar ratio of gallium nitrate or the corresponding gallium halide to lead halide is 5%—80%), form a clear liquid, stir evenly. Wherein, by controlling the molar ratio of gallium nitrate or the corresponding gallium halide to lead halide, the gallium ion doping ratio of the final perovskite quantum dot can be less than or equal to 5%.

[0093] Final reaction: quickly inject the aforementioned precursor solution into the toluene solution or the mixed solution of toluene and n-hexane / n-heptane / n-octane under vigorous stirring (the volume ratio of the precursor solution to toluene or the mixed solution is greater than or equal to 10) , centrifuge and precipitate, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com