Fluorine-doped titanium dioxide nano powder with transparent and near-infrared shielding functions

A technology of titanium dioxide and nano-powder, which is applied in the field of titanium dioxide nano-powder materials and fluorine-doped titanium dioxide nano-powder, which can solve the problems of high transmittance, low ion doping amount, and inability to guarantee, and achieve free electron concentration Improvement, simple preparation method, good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

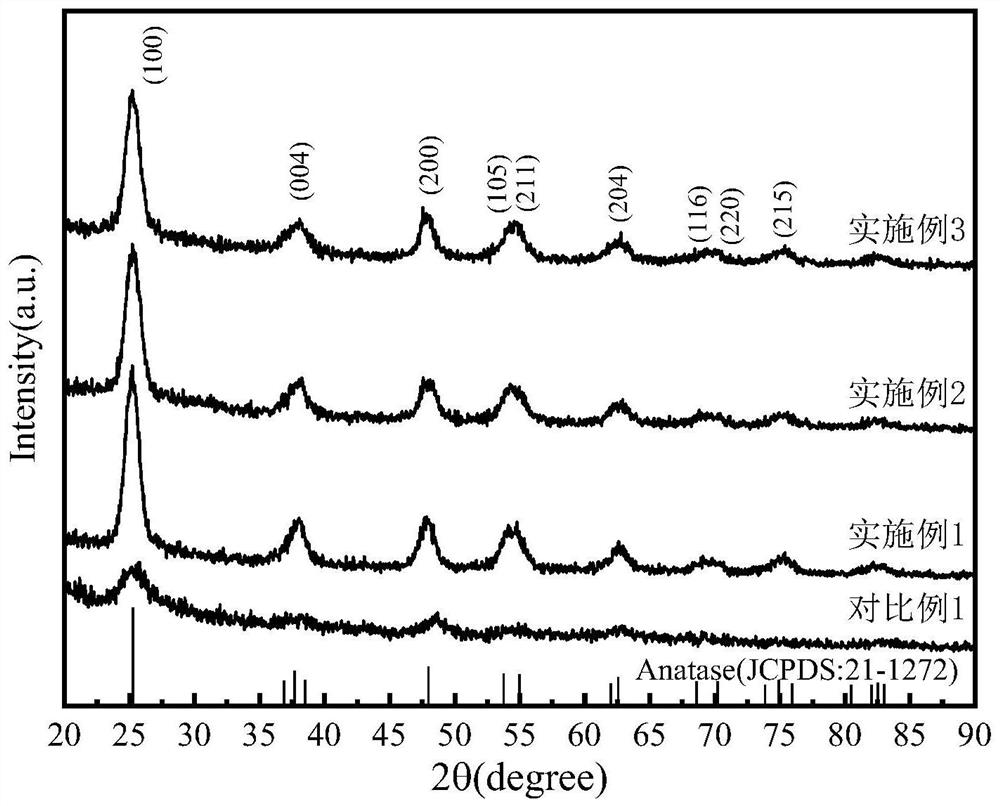

Embodiment 1

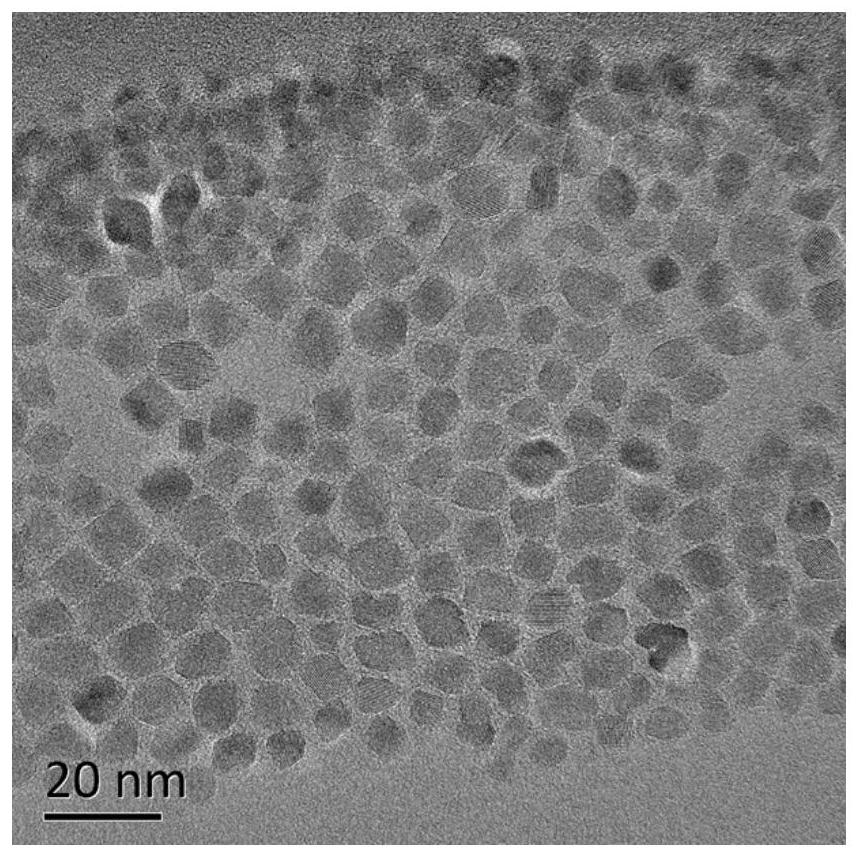

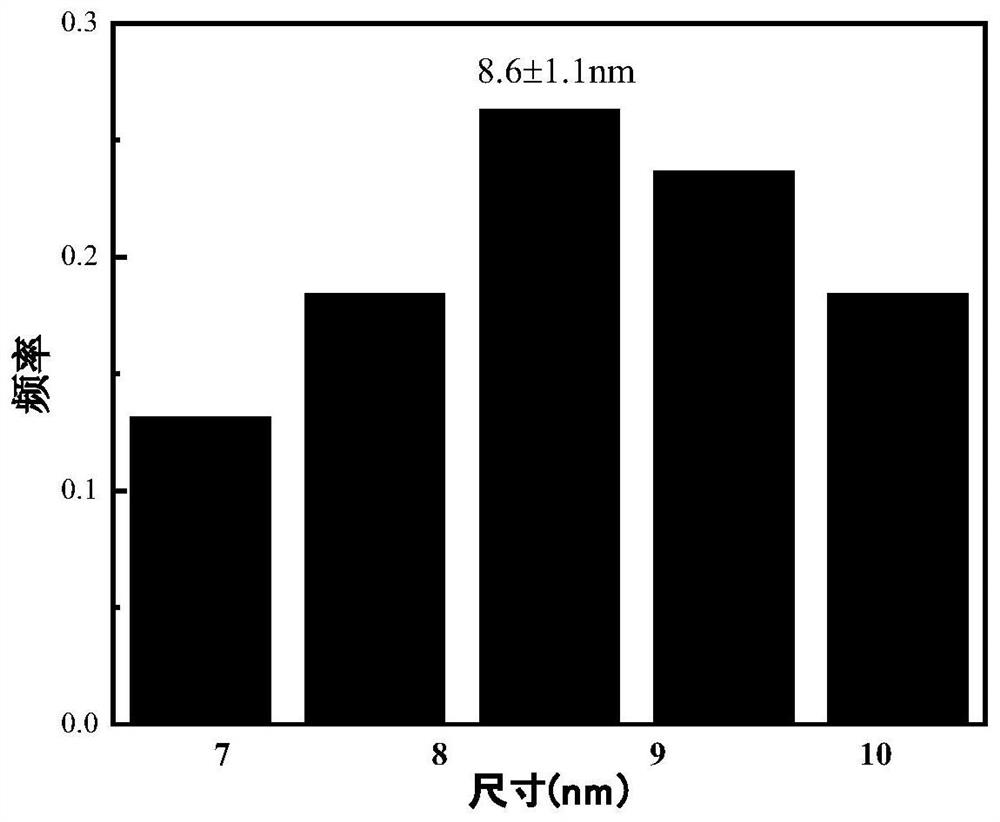

[0043] A method for preparing a fluorine-doped titanium dioxide nanopowder with both transparency and near-infrared shielding functions, comprising the following steps:

[0044] 1) Weigh 30mmol of stearyl alcohol, 3mmol of tetraethyl titanate, and 0.6mmol of ammonium fluoride into a 150ml three-necked flask, then add 1.5ml of oleylamine and oleic acid, and 24ml of octadecene to the three-necked flask;

[0045] 2) Put the three-necked flask into a heat-collecting constant temperature heating magnetic stirrer to heat and stir in an oil bath, and nitrogen gas is introduced during the heating process; on the one hand, nitrogen gas is used to create an inert atmosphere for easy doping, and on the other hand, it is used as a protective gas. Prevent organic matter from burning at high temperatures.

[0046] 3) When the temperature rises to 120°C, turn off the nitrogen gas, maintain the temperature at 120°C, and perform vacuum degassing for 20 minutes;

[0047] 4) After the degassing...

Embodiment 2

[0050] A method for preparing a fluorine-doped titanium dioxide nanopowder with both transparency and near-infrared shielding functions, comprising the following steps:

[0051] 1) Weigh 30mmol of stearyl alcohol, 3mmol of tetraethyl titanate, and 0.9mmol of ammonium fluoride into a 150ml three-necked flask, then add 1.5ml of oleylamine and oleic acid, and 24ml of octadecene to the three-necked flask;

[0052] 2) Put the three-necked flask into a heat-collecting constant temperature heating magnetic stirrer to heat and stir in an oil bath, and nitrogen gas is introduced during the heating process;

[0053] 3) When the temperature rises to 120°C, turn off the nitrogen gas, maintain the temperature at 120°C, and perform vacuum degassing treatment for 30 minutes;

[0054] 4) After the degassing is completed, continue to feed nitrogen, and raise the temperature to 280° C. for 60 minutes. After the reaction is over, cool the reactant to 60°C, first add 50ml of acetone and mix well...

Embodiment 3

[0057] A method for preparing a fluorine-doped titanium dioxide nanopowder with both transparency and near-infrared shielding functions, comprising the following steps:

[0058] 1) Weigh 30mmol of stearyl alcohol, 3mmol of tetraethyl titanate, and 1.2mmol of ammonium fluoride into a 150ml three-necked flask, then add 1.5ml of oleylamine and oleic acid, and 24ml of octadecene to the three-necked flask;

[0059] 3) Put the three-necked flask into a heat-collecting constant temperature heating magnetic stirrer to heat and stir in an oil bath, and nitrogen gas is introduced during the heating process;

[0060] 3) When the temperature rises to 120°C, turn off the nitrogen gas, maintain the temperature at 120°C, and perform vacuum degassing treatment for 30 minutes;

[0061] 4) After the degassing is completed, continue to feed nitrogen, and raise the temperature to 280° C. for 60 minutes. After the reaction is over, cool the reactant to 60°C, first add 50ml of acetone and mix well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com