Composite material and preparation method thereof and quantum dot light-emitting diode

A composite material and molar weight technology, applied in the field of nanomaterials, can solve the problems of unsatisfactory effect of electron transport materials, and achieve the effects of reducing donor ionization energy, increasing electrical conductivity, and self-compensating suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

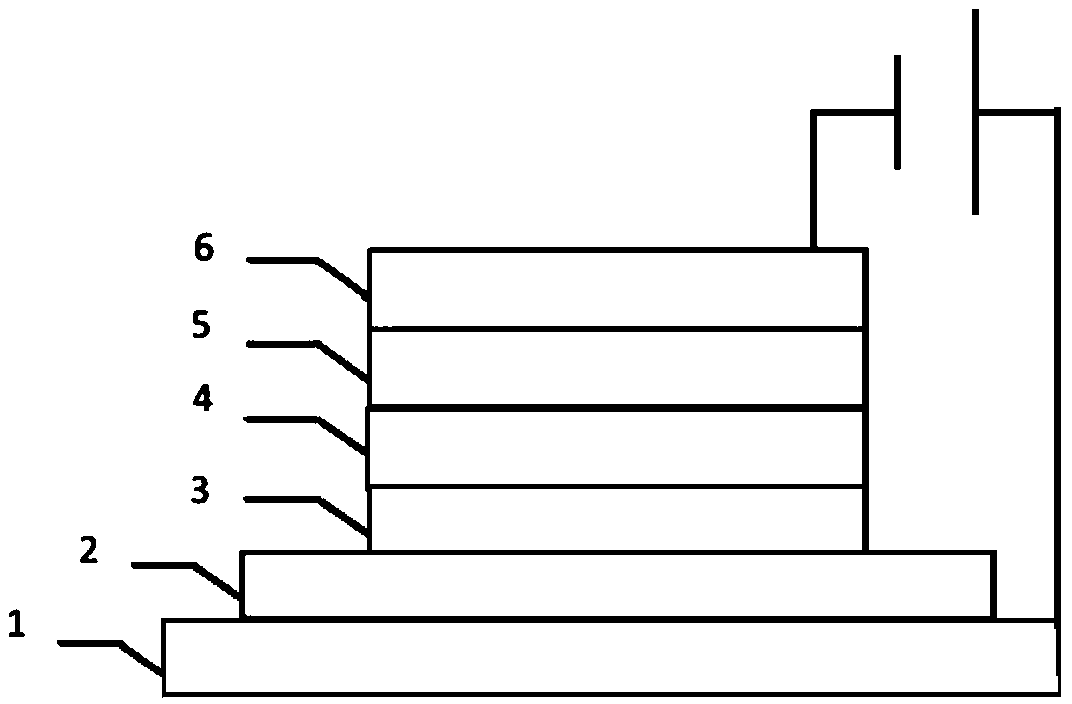

Image

Examples

preparation example Construction

[0021] On the other hand, the embodiment of the present invention also provides a method for preparing a composite material, comprising the following steps:

[0022] S01: Provide zinc salt, gallium salt, precursor salt containing selenium element and precursor salt containing sulfur element;

[0023] S02: dissolving the zinc salt, gallium salt, selenium-containing element precursor salt and sulfur-containing element precursor salt in a solvent, and performing heat treatment to obtain a precursor solution;

[0024] S03: Annealing the precursor solution to obtain the composite material.

[0025] In the composite preparation method provided in the embodiment of the present invention, the precursor solution is first prepared by using zinc salt, gallium salt, precursor salt containing selenium element and precursor salt containing sulfur element, and then the precursor solution is annealed to obtain a A kind of composite material of acceptor (Se)-donor (Ga) co-doped ZnS nanopartic...

Embodiment 1

[0049] Taking zinc chloride, sodium selenide, gallium chloride, ethanol, and sodium sulfide as examples, the preparation method of Se-Ga / ZnS composite material will be introduced in detail below.

[0050] 1) Add appropriate amount of zinc chloride, sodium selenide and gallium chloride to 50ml of ethanol to form a solution with a total concentration of 0.5M, wherein the molar ratio of zinc: selenium + gallium is 1:0.005; the molar ratio of selenium: gallium The ratio is 1:3. Stir at 70°C to dissolve.

[0051] 2) add the solution that sodium sulfide is dissolved in 10ml ethanol (molar ratio, S 2- :M x+ =1:1, M is zinc and gallium). Stirring was continued at 70 °C for 4 h to obtain a homogeneous solution.

[0052] 3) After the solution is cooled, spin-coat the treated ITO with a homogenizer and anneal at 250°C.

Embodiment 2

[0054] Taking zinc nitrate, potassium selenide, gallium nitrate, propanol, and potassium sulfide as examples, the preparation method of Se-Ga / ZnS composite material will be introduced in detail below.

[0055] 1) Add appropriate amount of zinc nitrate, potassium selenide and gallium nitrate to 50ml of propanol to form a solution with a total concentration of 0.5M, wherein the molar ratio of zinc: selenium + gallium is 1:0.005; the molar ratio of selenium: gallium It is 1:3. Stir to dissolve at 80°C.

[0056] 2) Add the solution that potassium sulfide is dissolved in 10ml propanol (molar ratio, S 2- :M x+ =1.1:1, M is zinc and gallium). Stirring was continued at 80 °C for 3 h to obtain a homogeneous solution.

[0057] 3) After the solution is cooled, spin-coat the treated ITO with a coater and anneal at 250°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com