Pesticide airplane spray aid and preparation method thereof

An adjuvant and anti-flying technology, which is applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problems of low effective utilization rate of pesticides, loss of pesticides, environmental pollution, etc., and achieve enhanced field anti-flying Efficacy, promote absorption, improve the effect of control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

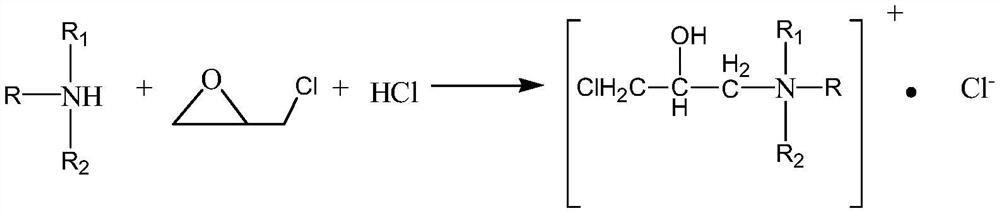

[0027] According to the preparation method of the anti-fly additive of the present invention, the method comprises the following steps: (1) preparing chlorohydroxypropyl alkylamine ether quaternary ammonium salt; (2) preparing the above-mentioned chlorohydroxypropyl alkylamine Ether quaternary ammonium salt and polyoxyethylene glyceryl ether, fatty alcohol polyoxyethylene ether, dioctyl sulfosuccinate sodium salt, block polyether, polynaphthalene sulfonate dispersing wetting agent, polymer anti-drift agent and water According to the weight ratio (20~25):(10~15):(15~20):(10~15):(10~15):(5~10):(5~10):(0~ 20) into the reaction kettle and stirred at 40°C for 2 hours until the material is uniform, and then the anti-flying additive is obtained. The chlorohydroxypropyl alkylamine ether quaternary ammonium salt described in step (1) is prepared according to the following steps: add alkylamine ether and water (accounting for 60% of the total reactant mass) in a closed reactor, and then...

Embodiment 1

[0033] Preparation of chlorohydroxypropyl alkylamine ether quaternary ammonium salt: add dodecylamine ether (EO=10) and water (accounting for 60% of the total reactant mass) in a closed reactor, then add epichlorohydrin dropwise (equal molar ratio to alkylamine ether), raise the temperature to 40°C, continue to stir for 4h, add HCl (equal molar ratio to alkylamine ether), and stir at 40°C for 2h to obtain the product chlorohydroxypropyl alkylamine ether quaternary ammonium salt.

[0034] Preparation of anti-flying auxiliary agent: according to the total amount of 100 parts, 10 parts of polyoxyethylene glyceryl ether, 20 parts of fatty alcohol polyoxyethylene ether, 25 parts of chlorohydroxypropyl alkylamine ether quaternary ammonium salt, sulfosuccinic acid di 10 parts of octyl ester sodium salt, 12 parts of special block polyether, 7 parts of polynaphthalene sulfonate dispersing and wetting agent, 7 parts of polymer anti-drift agent and 9 parts of water are added to the react...

Embodiment 2

[0036] Preparation of chlorohydroxypropyl alkylamine ether quaternary ammonium salt: add tetradecylamine ether (EO=15) and water (accounting for 60% of the total reactant mass) in a closed reactor, then add epichlorohydrin dropwise (equal molar ratio to alkylamine ether), raise the temperature to 40°C, continue to stir for 4h, add HCl (equal molar ratio to alkylamine ether), and stir at 40°C for 2h to obtain the product chlorohydroxypropyl alkylamine ether quaternary ammonium salt.

[0037] Preparation of anti-flying auxiliary agent: according to the total weight of 100 parts, 15 parts of polyoxyethylene glyceryl ether, 15 parts of fatty alcohol polyoxyethylene ether, 20 parts of chlorohydroxypropyl alkylamine ether quaternary ammonium salt, sulfosuccinic acid di 12 parts of octyl ester sodium salt, 10 parts of special block polyether, 10 parts of polynaphthalene sulfonate dispersing and wetting agent, 5 parts of polymer anti-drift agent and 13 parts of water are added to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com