Fruit and vegetable antibacterial material capable of actively removing ethylene and preparation process thereof

A technology of antibacterial material and preparation process, which is applied in the field of fruit and vegetable antibacterial materials that actively remove ethylene, can solve the problems of not optimizing the elimination of ethylene and prolonging the shelf life, and achieve the effects of reducing the concentration, prolonging the shelf life and improving the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

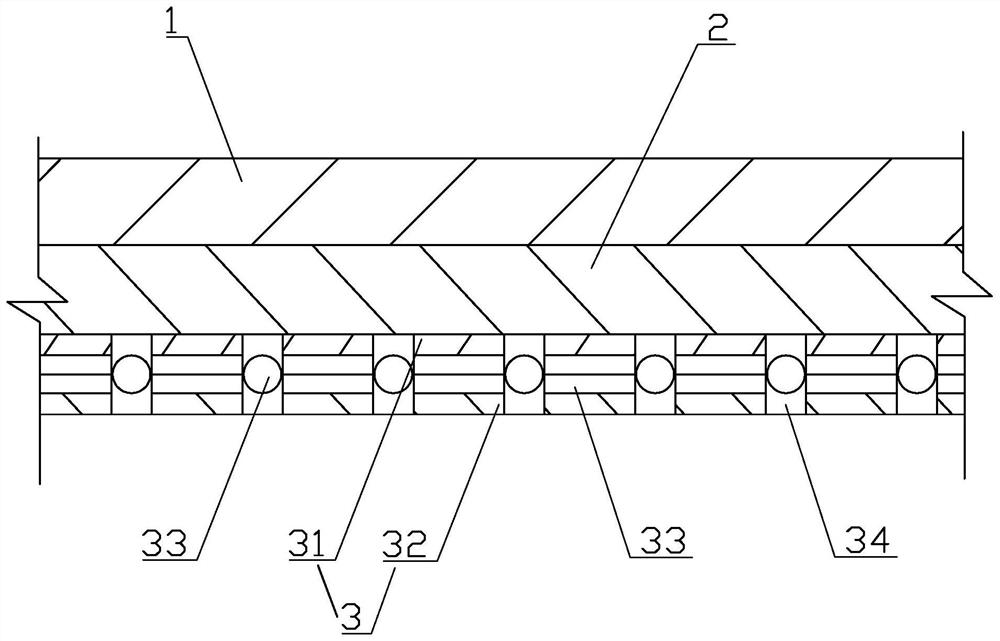

[0058] A fruit and vegetable antibacterial material that actively removes ethylene, such as figure 1 As shown, it includes a transparent barrier layer 1, a degradation layer 2 and an antibacterial layer 3 arranged in sequence. in:

[0059] The transparent barrier layer 1 is made of crosslinked dioctyl phthalate and polylactic acid.

[0060] Degradation layer 2 contains the following components:

[0061] Chitosan 85%

[0062] Glycerin 0.5%

[0063] Polyvinyl Alcohol 10%

[0064] Nano Titanium Dioxide 0.5%.

[0065] The antibacterial layer 3 includes an upper layer 31 and a lower layer 32 that are pressed against each other, the upper layer 31 is pressed against the degradation layer 2, and the lower layer 32 is used for direct contact with fruits and vegetables. The opposite surfaces of the upper layer 31 and the lower layer 32 are provided with air grooves 33, and the air grooves 33 are distributed in a grid pattern, and the air grooves 33 on the surface of the upper lay...

Embodiment 2

[0067] like figure 1 As shown, the difference between this embodiment and embodiment 1 is that, in this embodiment, the degradation layer 2 comprises the following components:

[0068] Chitosan 85%

[0069] Glycerin 0.5%

[0070] Polyvinyl alcohol 14%

[0071] Nano Titanium Dioxide 1%.

[0072] The difference between this embodiment and Embodiment 1 is that, in this embodiment, the silver ions in the silver ion antibacterial agent are introduced by silver nitrate solution.

Embodiment 3

[0074] like figure 1 As shown, the difference between this embodiment and embodiment 1 is that, in this embodiment, the degradation layer 2 comprises the following components:

[0075] Chitosan 80%

[0076] Glycerin 0.5%

[0077] Polyvinyl alcohol 18%

[0078] Nano Titanium Dioxide 1.5%.

[0079] The difference between this embodiment and Embodiment 1 is that, in this embodiment, the silver ions in the silver ion antibacterial agent are introduced by silver acetate solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com