A valve material with long-acting antithrombotic performance and its preparation method

An anti-thrombotic and valve technology, applied in the field of valve materials with long-term anti-thrombotic performance and its preparation, can solve the problems of easy calcification and thrombus formation, avoid calcium ion residues, improve anti-calcification performance, and improve anticoagulant function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

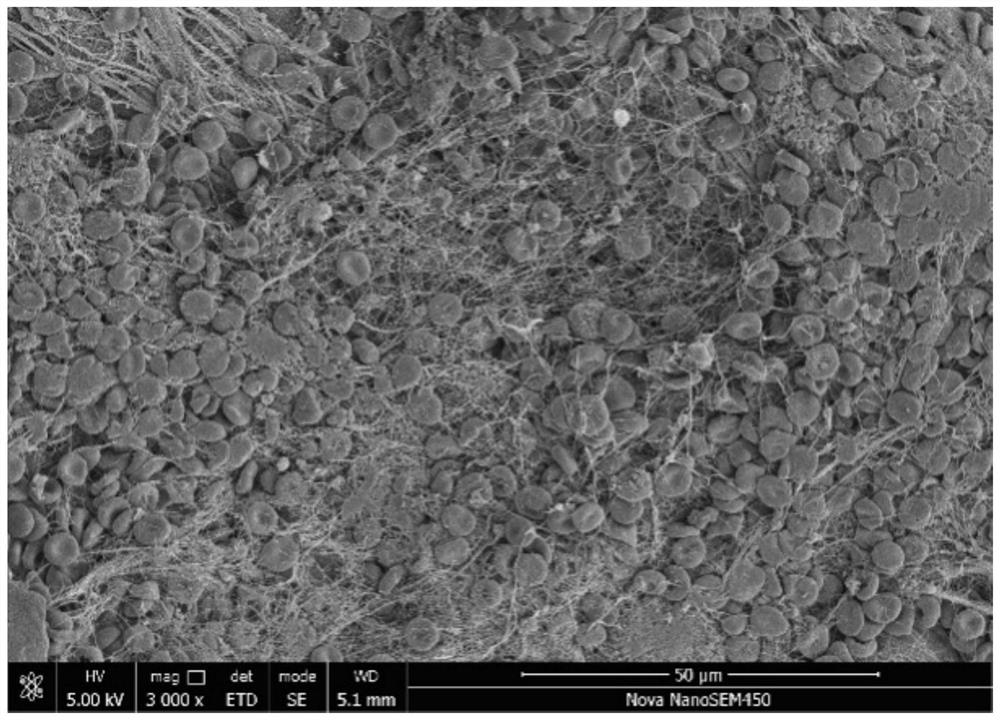

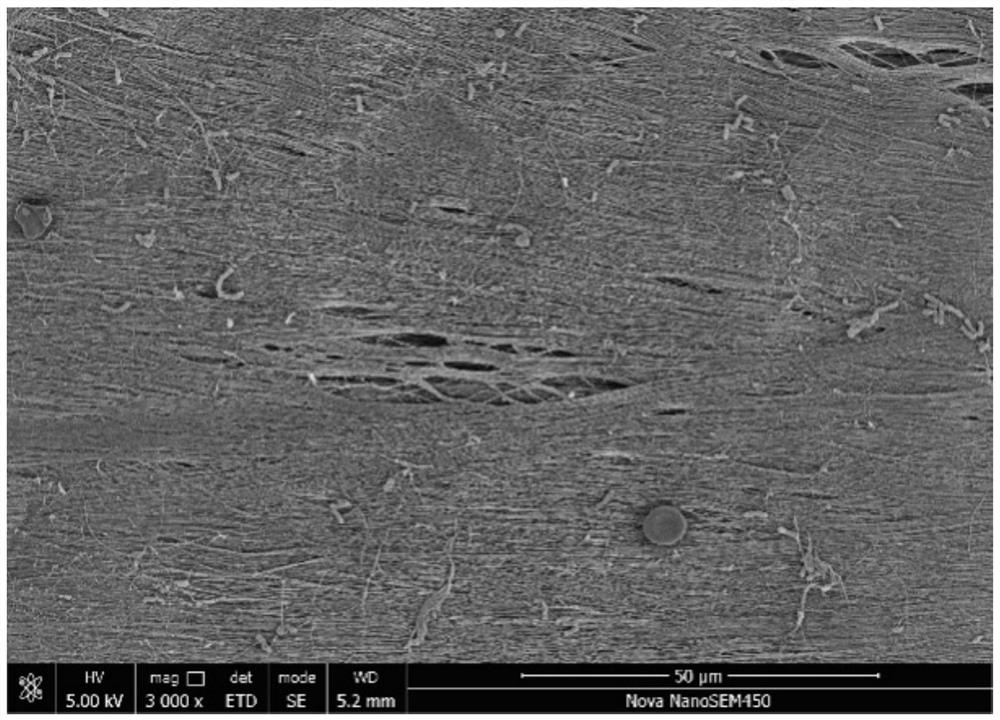

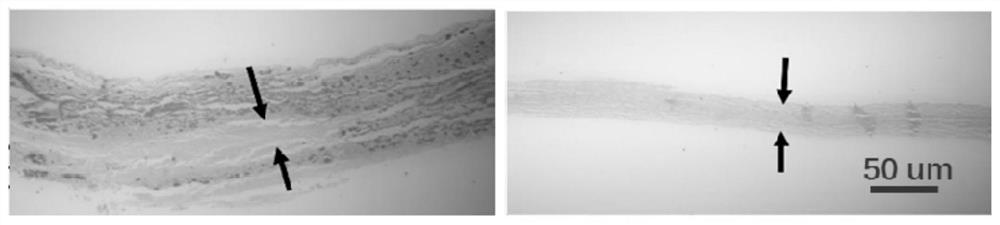

Image

Examples

Embodiment 1

[0032] A valve material with long-acting antithrombotic properties, the preparation method of which comprises the following steps:

[0033] (1) Cut the degreased pig pericardium material into a suitable size, soak it in 1% glutaraldehyde solution after stretching, change the solution every 24 hours, and continue the treatment for 72 hours;

[0034] (2) After cleaning the cross-linked valve material obtained above, immerse it in the formula solution for 30 minutes, the formula solution solvent is hexafluoroisopropanol, the cross-linking agent is sodium hexametaphosphate, and the modifier is glycerophosphocholine, The concentrations of sodium hexametaphosphate and glycerophosphorylcholine are 1 wt% and 0.5 wt%, respectively, and then the valve infiltrated by the formula solution is heated to 40 degrees, and heat-treated for 4 hours;

[0035] (3) The valve material obtained in step 2 is fully washed with deionized water to obtain the target valve material, and the material is sto...

Embodiment 2

[0037] A valve material with long-acting antithrombotic properties, the preparation method of which comprises the following steps:

[0038] (1) Cut the pig pericardium material after degreasing into suitable size, immerse in 0.5% glutaraldehyde solution for treatment for 24 hours after stretching, then transfer to 1% glutaraldehyde solution for treatment for 48 hours;

[0039] (2) After cleaning the cross-linked valve material obtained above, immerse it in the formula solution for 60 minutes, the formula solution solvent is isopropanol, the cross-linking agent is isocyanate, and the modifier is methacryloyl ethyl sulfobeet Alkali, lauryl methacrylate, butyl methacrylate copolymer, isocyanate, methacryloyl ethyl sulfobetaine, lauryl methacrylate, butyl methacrylate copolymer at concentrations of 0.1 wt%, 0.1wt%, 0.2wt% and 0.2wt%, then the valve infiltrated by the formula liquid was heated to 60 degrees, and heat treated for 3h;

[0040] (3) The valve material obtained in step...

Embodiment 3

[0042] A valve material with long-acting antithrombotic properties, the preparation method of which comprises the following steps:

[0043] (1) Cut the degreased bovine pericardium material into a suitable size, immerse it in 1% glutaraldehyde solution for 24 hours after stretching, and then transfer to 0.5% glutaraldehyde solution for 48 hours;

[0044] (2) After cleaning the cross-linked valve material obtained above, immerse it in the formula solution for 20 minutes, the formula solution solvent is water, the cross-linking agent is sodium metaphosphate, and the modifier is lauryl methacrylate, 2-(methyl Acryloyloxy)ethyl-2-(trimethylamino)ethyl phosphate copolymer, sodium metaphosphate, lauryl methacrylate, 2-(methacryloyloxy)ethyl-2- The concentrations of the (trimethylamino)ethyl phosphate copolymers were 1 wt%, 0.2 wt% and 0.3 wt%, respectively, and then the valve soaked in the formula liquid was heated to 50 degrees, and heat-treated for 8 hours;

[0045] (3) Fully was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com