Preparation method of layered nano hollow microsphere NiSiO coated NiAlFe adsorbent loaded with LDHs and application threof

A technology of hollow microspheres and adsorbents, applied in chemical instruments and methods, other chemical processes, nuclear engineering, etc., can solve the problems of high operating cost and low adsorption capacity, and achieve improved adsorption effect, high removal rate, and easy solution agglomerative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

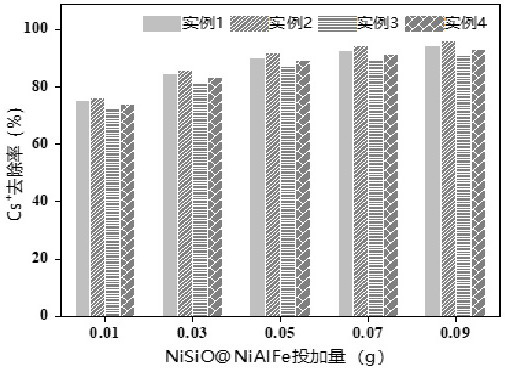

Examples

Embodiment 1

[0025] A method for preparing a layered nano-hollow microsphere NiSiO@NiAlFe adsorbent loaded with LDHs, comprising the following steps:

[0026] a) Template SiO 2 preparation of

[0027] 9 mL of ethyl orthosilicate, 4 mL of deionized water, and 100 mL of ammonia water were sequentially added to 100 mL of absolute ethanol, followed by stirring at room temperature for 5 h. After the mixed solution was centrifuged for 5 minutes, the obtained solid was washed three times with ultrapure water, dried at 60° C. for 12 hours, ground and passed through a 200-mesh sieve to obtain white nano-spherical silica powder.

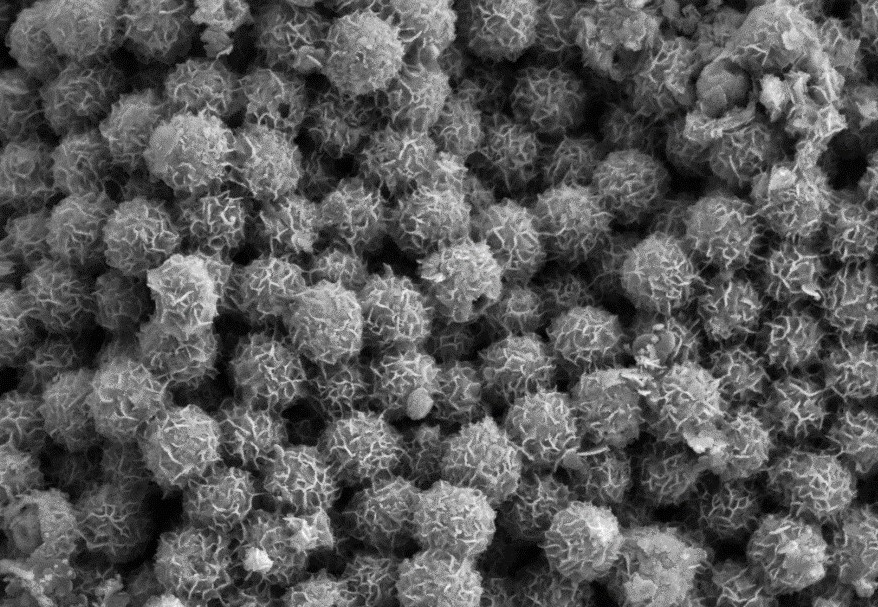

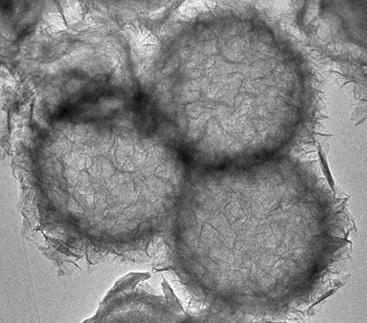

[0028] b) Preparation of NiSiO hollow spheres

[0029] 0.4g SiO 2 Disperse in 80mL of water and sonicate for 10min to form suspension A. 5.4mmol Ni(NO 3 ) 2 ·6H 2 O, 20 mmol NH 4 Dissolve Cl in 80mL ultrapure water and stir for about 15min, then slowly add 4mL NH 3 ·H 2 O, forming solution B. Solution B was added dropwise to suspension A to form a mixed solution...

Embodiment 2

[0033] A method for preparing a layered nano-hollow microsphere NiSiO@NiAlFe adsorbent loaded with LDHs, comprising the following steps:

[0034] a) Template SiO 2 preparation of

[0035] 9 mL of ethyl orthosilicate, 4 mL of deionized water, and 100 mL of ammonia water were sequentially added to 100 mL of absolute ethanol, followed by stirring at room temperature for 5 h. After the mixed solution was centrifuged for 5 minutes, the obtained solid was washed three times with ultrapure water, dried at 60° C. for 12 hours, ground and passed through a 200-mesh sieve to obtain white nano-spherical silica powder.

[0036] b) Preparation of NiSiO hollow spheres

[0037] 0.4g SiO 2 Disperse in 80mL of water and sonicate for 10min to form suspension A. 5.4mmol Ni(NO 3 ) 2 ·6H 2 O, 20 mmol NH 4 Dissolve Cl in 80mL ultrapure water and stir for about 15min, then slowly add 4mL NH 3 ·H 2 O, forming solution B. Solution B was added dropwise to suspension A to form a mixed solution...

Embodiment 3

[0041] A method for preparing a layered nano-hollow microsphere NiSiO@NiAlFe adsorbent loaded with LDHs, comprising the following steps:

[0042] a) Template SiO 2 preparation of

[0043] 9 mL of ethyl orthosilicate, 4 mL of deionized water, and 100 mL of ammonia water were sequentially added to 100 mL of absolute ethanol, followed by stirring at room temperature for 5 h. After the mixture was centrifuged for 5 minutes, the obtained solid was washed 3 times with ultrapure water, dried at 60°C for 12 hours, ground and passed through a 200-mesh sieve to obtain white nano-spherical SiO 2 Powder.

[0044] b) Preparation of NiSiO hollow spheres

[0045] 0.4g SiO 2 Disperse in 80mL of water and sonicate for 10min to form suspension A. 5.4mmol Ni(NO 3 ) 2 ·6H 2 O, 20 mmol NH 4 Dissolve Cl in 80mL ultrapure water and stir for about 15min, then slowly add 4mL NH 3 ·H 2 O, forming solution B. Solution B was added dropwise to suspension A to form a mixed solution. Finally, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com