Preparation method of carbon-loaded platinum-based alloy catalyst

A technology of platinum-based alloys and catalysts, which is applied in the field of preparation of carbon-supported platinum-based alloy catalysts, can solve problems such as unsatisfactory use and inability to form platinum-based alloys, and achieve benefits for industrial production, reduce fluidity, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

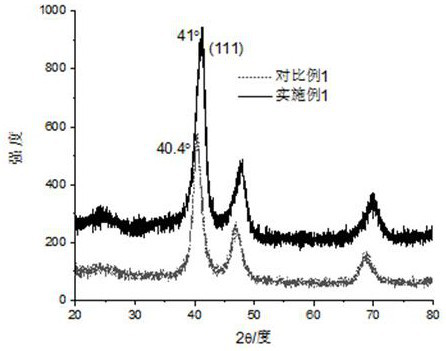

Embodiment 1

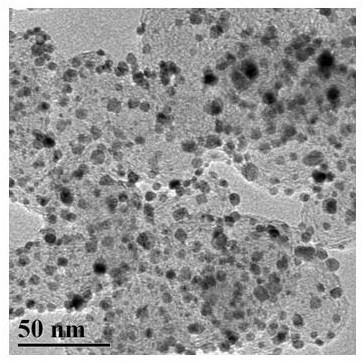

[0023] A preparation method of a carbon-supported platinum-nickel alloy catalyst is carried out in sequence according to the following steps:

[0024] (1) In the aqueous solution containing 200 mg of potassium chloroplatinate and 22 mg of nickel chloride, add 268 mg of activated carbon to obtain a mixed slurry;

[0025] (II) Place the mixed slurry prepared in step I in an ice bath, and cool the mixed slurry to 0°C under stirring;

[0026] (Ⅲ) Quickly adjust the pH value of the cooled mixed slurry in the second step to 12~14 with a strong alkali solution of sodium hydroxide within 2 minutes;

[0027] (IV) Quickly freeze the mixed slurry after adjusting the pH value in step III with liquid nitrogen within 1 minute, and then freeze-dry in liquid nitrogen to obtain the precursor of platinum-nickel alloy;

[0028] (Ⅴ) Put the freeze-dried platinum-nickel alloy precursor prepared in Section IV in a mixed reducing atmosphere with a volume ratio of hydrogen and nitrogen of 5:95, heat...

Embodiment 2

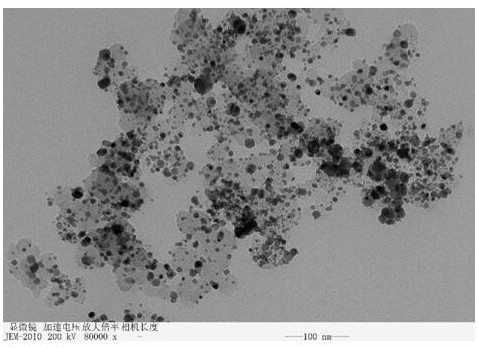

[0036] A preparation method of a carbon-supported platinum-cobalt alloy catalyst is carried out in sequence according to the following steps:

[0037] (I) Add 375 mg of carbon fiber to an aqueous solution containing 300 mg of sodium chloroplatinite and 90 mg of cobalt acetate to obtain a mixed slurry;

[0038] (II) Place the mixed slurry prepared in step I in an ice bath, and cool the mixed slurry to -2°C under stirring;

[0039] (Ⅲ) Quickly adjust the pH value of the cooled mixed slurry in the second step to 12~14 with potassium hydroxide strong alkali solution within 3 minutes;

[0040] (IV) The mixed slurry after adjusting the pH value in step III is quickly frozen with liquid nitrogen within 30 seconds, and then freeze-dried in liquid nitrogen to obtain the precursor of platinum-cobalt alloy;

[0041] (Ⅴ) Put the freeze-dried platinum-cobalt alloy precursor prepared in IV in a mixed reducing atmosphere with a volume ratio of hydrogen and nitrogen of 5:95, heat treatment a...

Embodiment 3

[0044] A preparation method of a carbon-supported platinum-copper alloy catalyst is carried out in sequence according to the following steps:

[0045] (I) Add 240 mg of graphene to the aqueous solution containing 400 mg of chloroplatinic acid and 100 mg of copper sulfate to obtain a mixed slurry;

[0046] (II) Place the mixed slurry prepared in step I in an ice bath, and cool the mixed slurry to 1 °C under stirring conditions;

[0047] (Ⅲ) Quickly adjust the pH value of the cooled mixed slurry in the second step to 12~14 with a strong alkali solution of sodium hydroxide within 5 minutes;

[0048] (IV) The mixed slurry after adjusting the pH value in step III was quickly frozen with liquid nitrogen within 2 minutes, and then freeze-dried in liquid nitrogen to obtain the precursor of platinum-copper alloy;

[0049] (Ⅴ) The freeze-dried platinum-copper alloy precursor prepared in step IV is subjected to a heat preservation heat treatment at a rate of 10°C / min to 700°C for 8 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com