Preparation method of sulfur-carbon-based solid acid catalyst

A solid acid catalyst, sulfur carbon-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve high cost, environmental pollution, sulfur-containing carrier Difficult to obtain and other problems, to achieve the effect of increased catalytic activity and safe transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of sulfur-carbon-based solid acid of the present invention, it mixes carbon source and sulfur source and heats, and oxidizes the obtained sulfur-containing carbon carrier with one or more of hydrogen peroxide, peracetic acid, etc., or Alkaline hydrolysis is carried out with sodium hydroxide, potassium hydroxide, etc., and the preparation methods of the sulfur-carbon-based solid acid catalyst of the present invention and these substances are described in detail below.

[0029] The raw materials of the sulfur-carbon-based solid acid of the present invention are the carbon source and the sulfur source. There is no special limitation on the carbon source. In the carbon-based solid acid of the present invention, the carbon source is any carbon-containing substance, such as sugars, lignin, naphthalene , anthracene, pitch, and carbon sources can be used alone or in combination of two or more.

[0030] In the following embodiments of the thiocarbon-based so...

Embodiment 1

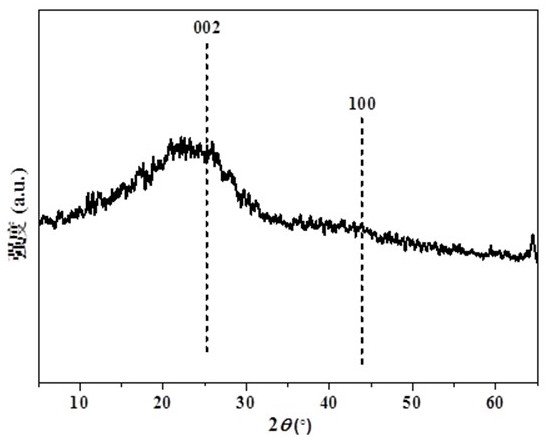

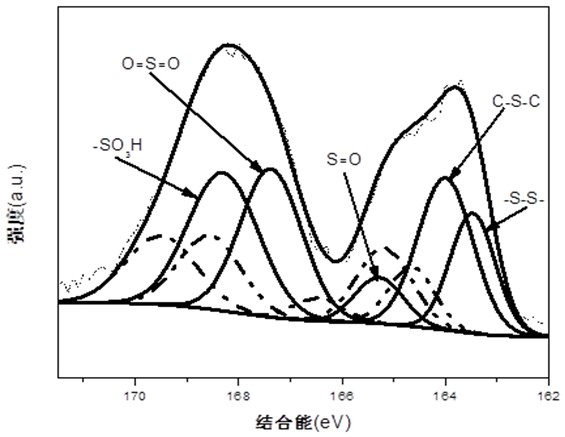

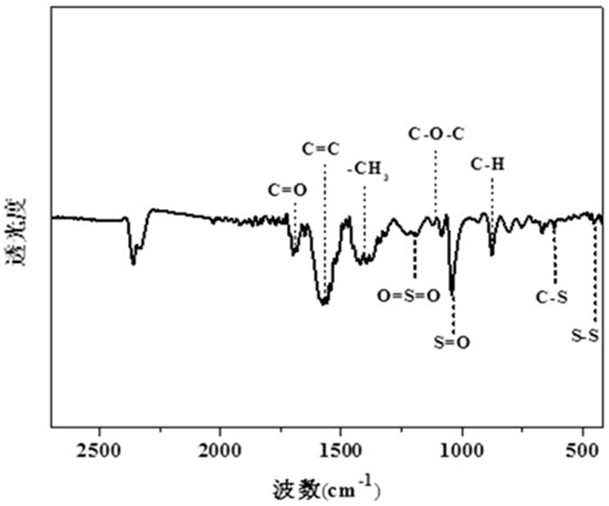

[0033] After mixing the cellulose and sulfur evenly in a ratio of 10:1, weigh a certain mass of the mixture and carbonize it at 440°C under nitrogen to obtain a black solid, which is the sulfur-containing carbon carrier; oxidize the obtained sulfur-containing carbon carrier at 4mol / L Alkaline hydrolysis with sodium at 150°C for 6 hours, cooling, washing, filtering, and drying to obtain sulfocarbon-based solid acid; the sulfur content was detected to be 3.0% by analysis, and sulfonic acid was removed from the structure of thiocarbon-based solid acid. In addition to the base, the sulfur carbon-based solid acid generally contains S=O, C-S-C and O=S=O. In a reactor with a condensing reflux device, the sulfur carbon-based solid acid and methanol are in the ratio of 1g: 5ml. React in the heating device of the high-speed magnetic stirring device, react at a temperature of 70°C for 2 hours, and calculate the conversion rate of oleic acid to be 41.2%; then take a quantitative amount of ...

Embodiment 2

[0035] After mixing cellulose and sodium thiosulfate uniformly according to a certain ratio of 2:1, weigh a certain mass of the mixture and carbonize it at 700°C under nitrogen to obtain a black solid that is the sulfur-containing carbon carrier; / L sodium hydroxide was alkaline hydrolyzed at 100°C for 8 hours, cooled, washed, filtered, and dried to obtain a sulfocarbon-based solid acid; the sulfur content was 15.4% as determined by a sulfur analyzer, and the thiocarbon-based solid acid was obtained by XRS analysis. In the structure of solid acid, except for the sulfonic acid group, the structure of sulfur carbon-based solid acid is O=S=O, C-S-C, S-S. In a reactor with a condensation reflux device, mix sulfur carbon-based solid acid and methanol by 1g: The proportion of 5ml was reacted in a heating device with a constant speed magnetic stirring device, and the reaction was carried out at a temperature of 70°C for 2 hours, and the conversion rate of oleic acid was calculated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com