Insulating substrate and preparation method and application thereof

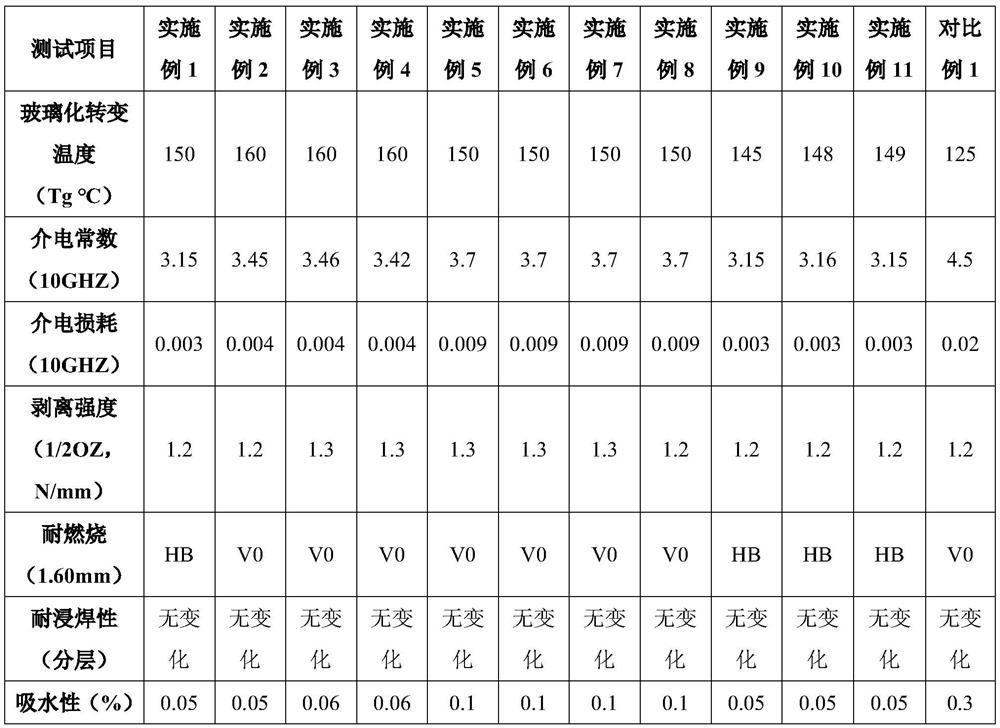

A technology for insulating substrates and copper-clad laminates, which can be used in other household appliances, chemical instruments and methods, applications, etc., can solve problems such as the complexity of prepolymer preparation methods, and achieve improved glass transition temperature and excellent dielectric properties , The effect of reducing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1, the preparation of high-frequency high-speed copper-clad laminate of the present invention

[0066] Blend dicyclopentadiene and ruthenium carbene catalyst at a weight ratio of 10000:2, stir and mix evenly to obtain glue, select 200*200mm E-glass fiber cloth, apply the above glue evenly, and cure at 60°C for 10 minutes , to obtain an insulating substrate. Coat the surface of 35 micron thick copper foil with phenolic resin adhesive (you can also apply phenolic resin adhesive on both sides of the insulating substrate), then place two pieces of copper foil on both sides of the insulating substrate respectively, and place them in a vacuum hot press machine to press to obtain For copper clad laminates, the temperature and time of vacuum hot pressing are 150°C for 10 minutes.

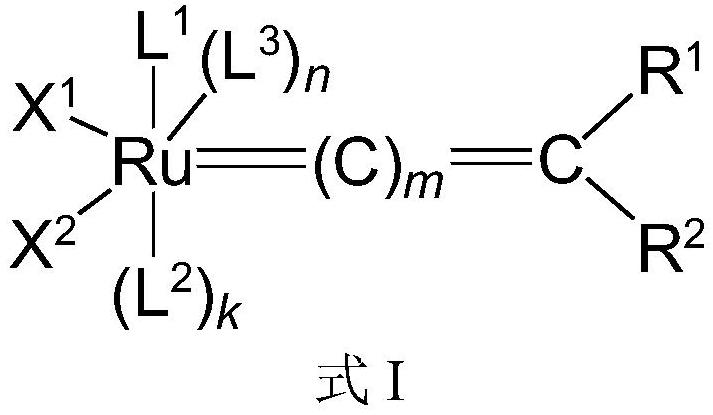

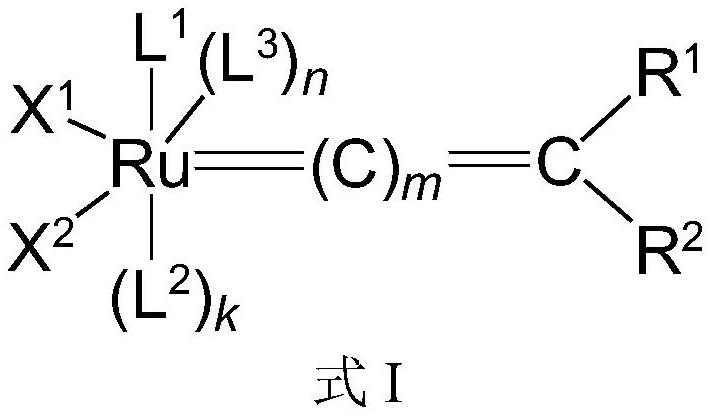

[0067] The ruthenium carbene catalyst used in this embodiment is

Embodiment 2

[0068] Example 2. Preparation of high-frequency and high-speed flame-retardant copper-clad laminates of the present invention

[0069] Blend dicyclopentadiene, ruthenium carbene catalyst, silica glass beads, and decabromodiphenylethane according to a weight ratio of 10000:2:5000:1000, stir and mix evenly to obtain a glue solution, select 200*200mm E-glass fiber cloth, evenly coated with the above glue, cured at 60°C for 10 minutes to obtain an insulating substrate. Coat the surface of 35 micron thick copper foil with phenolic resin adhesive (you can also apply phenolic resin adhesive on both sides of the insulating substrate), then place two pieces of copper foil on both sides of the insulating substrate respectively, and place them in a vacuum hot press machine to press to obtain For copper clad laminates, the temperature and time of vacuum hot pressing are 150°C for 10 minutes.

[0070] The ruthenium carbene catalyst used in this embodiment is

Embodiment 3

[0071] Embodiment 3, the preparation of high-frequency high-speed copper-clad laminate of the present invention

[0072] Cycloolefin compounds (composed of dicyclopentadiene and norbornene, the weight ratio of dicyclopentadiene and norbornene is 9:1), ruthenium carbene catalyst, silica glass beads, hexabromocyclododeca Alkanes are blended according to the weight ratio of 10000:2:5000:1000, stirred and mixed evenly to obtain glue, select 200*200mm E-glass fiber cloth, apply the above glue evenly, and cure at 60°C for 10 minutes to obtain insulation substrate. Coat the surface of 35 micron thick copper foil with phenolic resin adhesive (you can also apply phenolic resin adhesive on both sides of the insulating substrate), then place two pieces of copper foil on both sides of the insulating substrate respectively, and place them in a vacuum hot press machine to press to obtain For copper clad laminates, the temperature and time of vacuum hot pressing are 150°C for 10 minutes.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com