Method for processing and modifying casting dust into natural rubber reinforcing agent

A natural rubber, processing and modification technology, applied in the field of solid waste resource recycling, can solve the problems of high energy consumption, achieve low energy consumption, reduce primary energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

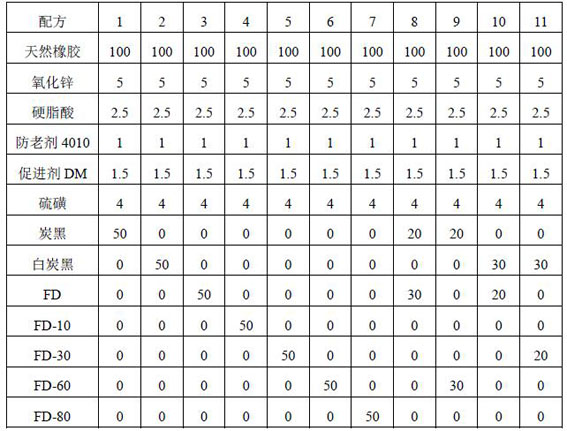

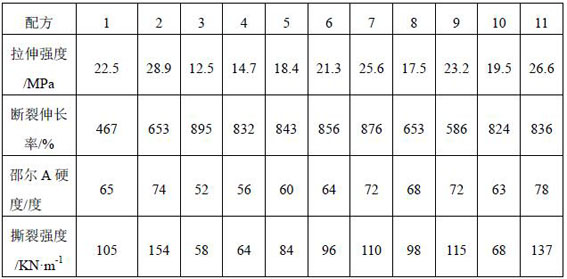

Examples

Embodiment 1

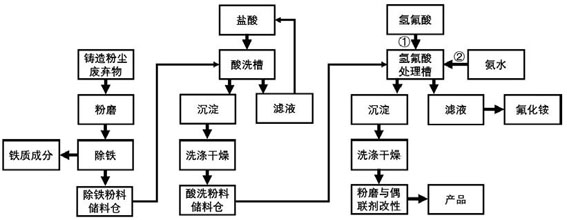

[0025] Step 1: use a micropowder mill to grind 100 parts by mass of foundry dust to an average particle size of less than 50 microns, and then use a magnetic separator to remove iron;

[0026] The second step: use industrial hydrochloric acid with a concentration of 20% as the pickling solution to pickle the foundry dust after iron removal, use 1000 parts by mass of pickling solution for every 100 parts by mass of foundry dust, and pickle under slow stirring for 4 h, let it stand until the foundry dust is completely settled, and then separate the solid and liquid by filtration;

[0027] Step 3: Wash the pickled foundry dust with water until neutral, add 440 parts by mass of tap water to 100 parts by mass of foundry dust, then add 60 parts by mass of 20% hydrofluoric acid solution, and stir mechanically until the foundry dust is in suspension Dispersed state and fully mixed for 8 hours; slowly add 5% ammonia water under continuous stirring until the pH value of the solution is ...

Embodiment 2

[0030] The first step: the same as the first step in embodiment 1;

[0031] Second step: same as the second step of embodiment 1;

[0032] Step 3: Wash the pickled foundry dust with water until neutral, add 200 parts by mass of tap water to 100 parts by mass of foundry dust, then add 300 parts by mass of 20% hydrofluoric acid solution, and stir mechanically until the foundry dust is in suspension Dispersed state and fully mixed for 8 hours; slowly add 5% ammonia water under continuous stirring until the pH value of the solution is greater than 12, continue to stir for 2 hours after adding ammonia water, let stand to make the solid matter fully precipitate, separate the solid and liquid by filtration, and the solid precipitate Wash and dry for later use;

[0033] The fourth step: the same as the fourth step of Example 1; the obtained modified foundry dust rubber reinforcing agent is marked as FD-40.

Embodiment 3

[0035] The first step: the same as the first step in embodiment 1;

[0036] The second step: use industrial hydrochloric acid with a concentration of 20% as the pickling solution to pickle the foundry dust after iron removal, use 2000 parts by mass of pickling solution per 100 parts by mass of foundry dust, pickle under slow stirring for 8 h, let it stand until the foundry dust is completely settled, and then separate the solid and liquid by filtration;

[0037] Step 3: Wash the pickled foundry dust with water to neutrality, add 100 parts by mass of foundry dust to 100 parts by mass of tap water, then add 400 parts by mass of 20% hydrofluoric acid solution, and mechanically stir until the foundry dust is in suspension Dispersed state and fully mixed for 8 hours; slowly add 5% ammonia water under continuous stirring until the pH value of the solution is greater than 12, continue to stir for 2 hours after the ammonia water is added, let it stand for the solid matter to fully pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com