Treatment method for improving surface strength of Al-Mg alloy

A technology of surface strength and treatment method, which is applied in the field of treatment to improve the surface strength of Al-Mg alloys, can solve the problems of easy cracking and obvious problems of materials, and achieve the effects of improving mechanical properties, prolonging life, and improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

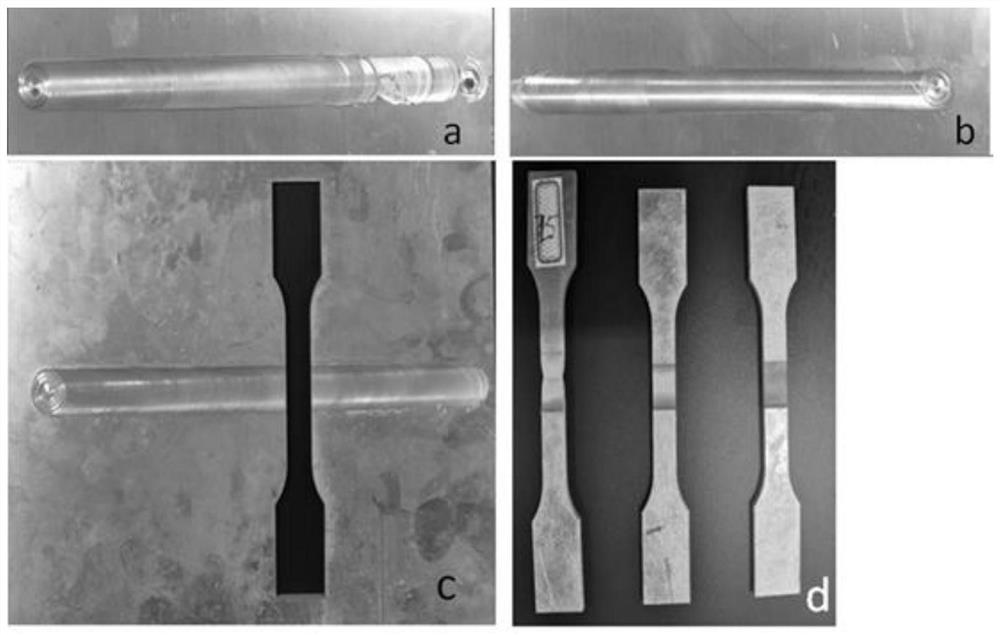

Image

Examples

Embodiment 1

[0024] A treatment method for improving the surface strength of Al-Mg series alloy——5052 aluminum alloy, comprising the following sequential steps:

[0025] (1) Take a 5052 aluminum alloy sheet material with a length of 120mm, a width of 60mm, and a thickness of 6mm. The 5052 aluminum alloy is polished and peeled at room temperature. Soak in 20g / L nitric acid for 2 minutes, then wash with alcohol and dry;

[0026] (2) After the step (1) is completed, place the 5052 aluminum alloy sheet in a heating furnace at 450°C for 30 minutes for preheating;

[0027] (3) Immediately perform friction stir processing on the 5052 aluminum alloy sheet after the preheating treatment. The feed speed of the alloy sheet is 35mm / min;

[0028] (4) Grinding the burrs existing after the friction stir addition treatment, and finally performing a cold rolling forming treatment with a reduction of 50%.

Embodiment 2

[0030] A treatment method for improving the surface strength of an Al-Mg alloy—a 6061 aluminum alloy, comprising the following sequential steps:

[0031] (1) Take a 6061 aluminum alloy sheet with a length of 120 mm, a width of 60 mm, and a thickness of 6 mm. At room temperature, the 5052 aluminum alloy is polished and peeled. First, soak it in a sodium hydroxide solution with a concentration of 50 g / L for 2 minutes. Soak in 30g / L nitric acid for 1 minute, then wash with alcohol and dry;

[0032] (2) After the step (1) is completed, the 6061 aluminum alloy sheet is placed in a heating furnace at 480° C. for 40 minutes for preheating;

[0033] (3) Immediately perform friction stir processing on the 6061 aluminum alloy sheet after the preheating treatment. The inclination angle of the stirring head is 2°, the rotation speed of the stirring head is 1200r / min, and the depression of the shoulder of the stirring head is 0.5mm. The feed speed of the alloy sheet is 50mm / min;

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com