Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, carbon preparation/purification, etc., can solve the problems of low specific capacity and stability, improve specific capacity and stability, and improve bonding degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

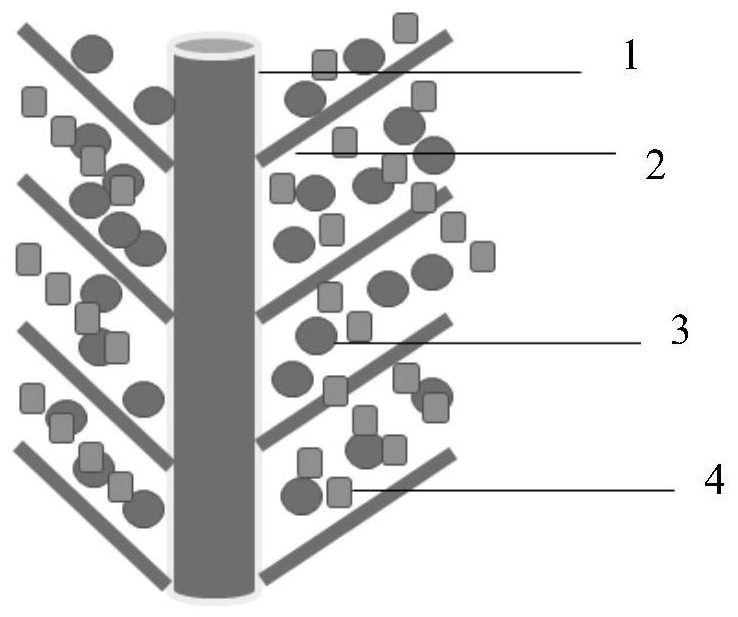

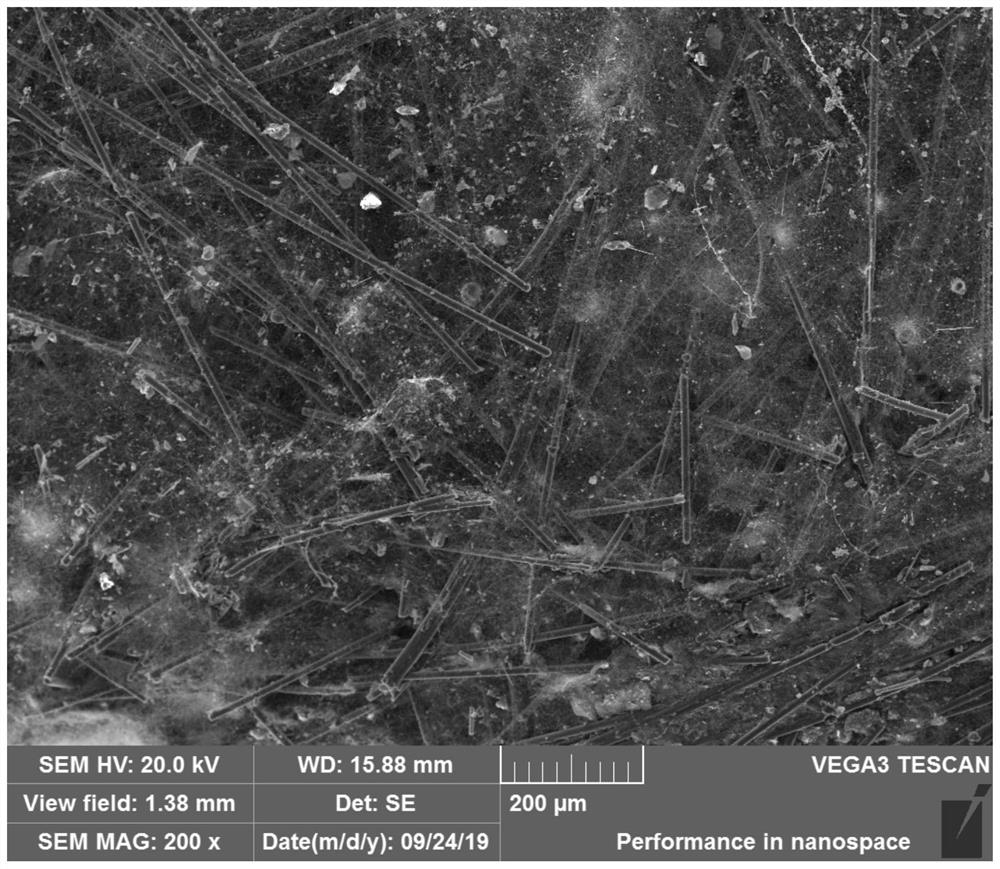

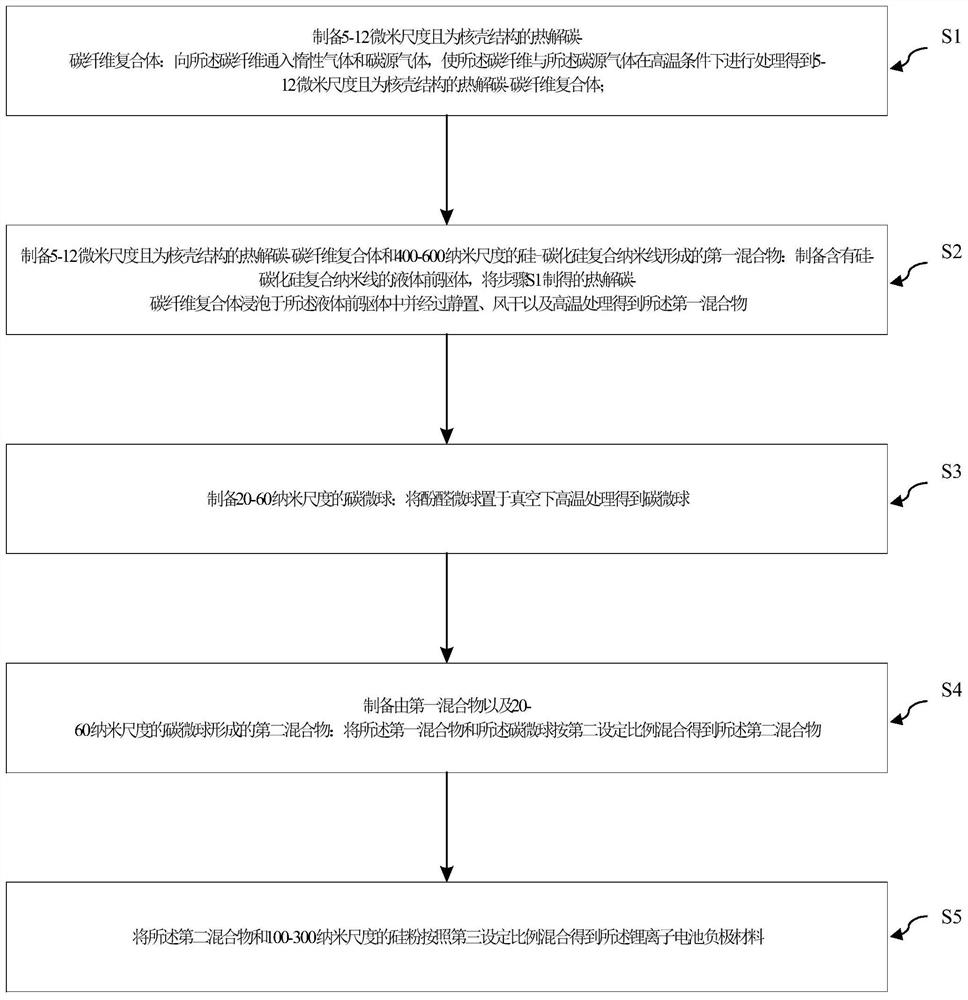

[0045] Such as image 3 Shown, the preparation method of this lithium-ion battery negative electrode material comprises the following steps:

[0046] S1. Preparation of pyrolytic carbon-carbon fiber composites with a scale of 5-12 microns and a core-shell structure: pass inert gas and carbon source gas into the carbon fibers, and process the carbon fibers and carbon source gas at high temperature to obtain 5-12 microns Pyrolytic carbon-carbon fiber composites with a core-shell structure.

[0047] Wherein, the inert gas may be argon, and the carbon source gas may be methane; the flow rate of the carbon source gas may be 0.2-0.5 L / min; the flow rate of the inert gas may be 0.5-1.0 L / min.

[0048] Specifically, in some embodiments, the carbon fiber can be placed in a high-temperature furnace at a temperature of 800-1000 degrees, and methane and argon can be passed through for 1-3 hours to obtain a 5-12 micron scale and a core-shell structure. pyrolytic carbon-carbon fiber compo...

Embodiment 1

[0058] (1) Put the carbon fiber in a high-temperature furnace, and treat it for 1 hour at a temperature of 800 degrees, a methane flow rate of 0.2L / min, and an argon flow rate of 0.5L / min to obtain sample A; sample A is 5-12 Pyrolytic carbon-carbon fiber composites with micron scale and core-shell structure.

[0059] (2) Mix ethyl orthosilicate and absolute ethanol in a molar ratio of 1:5, stir evenly, then add hydrochloric acid, the ratio of hydrochloric acid to ethyl orthosilicate is 1:10, continue stirring for 1 hour, and the obtained liquid Marked as B; B is the liquid precursor containing silicon-silicon carbide composite nanowires.

[0060] Soak sample A in liquid B, immerse at room temperature for 36 hours, and dry naturally in the air to obtain a sample marked as C; where C is a pyrolytic carbon-carbon fiber composite mixed with a liquid precursor.

[0061] Sample C was placed in an argon atmosphere, under the condition of 1000 degrees, high-temperature heat treatment...

Embodiment 2

[0066] (1) Put the carbon fiber in a high-temperature furnace, and treat it for 3 hours at a temperature of 1000 degrees, a methane flow rate of 0.5L / min, and an argon flow rate of 1.0L / min to obtain sample A; sample A is 5-12 Pyrolytic carbon-carbon fiber composites with micron scale and core-shell structure.

[0067] (2) Mix ethyl orthosilicate and absolute ethanol in a molar ratio of 1:2, stir evenly, then add hydrochloric acid, the ratio of hydrochloric acid to ethyl orthosilicate is 1:15, continue stirring for 2 hours, and the obtained liquid Marked as B; B is the liquid precursor containing silicon-silicon carbide composite nanowires.

[0068] Soak sample A in liquid B, immerse at room temperature for 48 hours, and dry naturally in the air to obtain a sample marked as C; where C is a pyrolytic carbon-carbon fiber composite mixed with a liquid precursor.

[0069] Sample C was placed in an argon atmosphere, subjected to high-temperature heat treatment at 1200 degrees for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com