High-temperature high-voltage electrolyte matched with silicon-carbon negative electrode material lithium-ion battery

A lithium-ion battery and anode material technology, applied in the field of lithium-ion power battery electrolyte, can solve the problems of large volume expansion of silicon-carbon anode materials, destruction of electrode conductive network, battery capacity attenuation, etc., to reduce the occurrence of side reactions and reduce HF Content, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

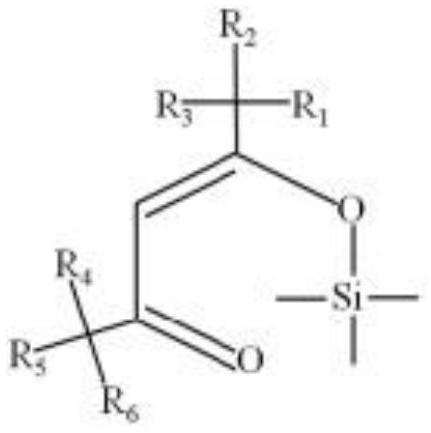

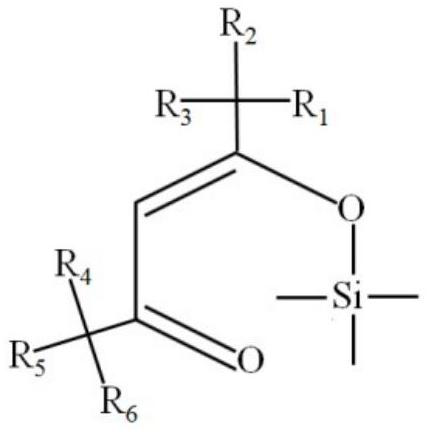

Method used

Image

Examples

Embodiment 1

[0019] In a glove box filled with argon (moisture 4 f 2 , and then slowly add 12.5% LiPF based on the total mass of the electrolyte to the mixed solution 6 , and stirred until it was completely dissolved to obtain the lithium-ion power battery electrolyte of Example 1.

[0020] Inject the prepared lithium-ion power battery electrolyte into the positive electrode LiNi 0.5 co 0.2 mn 0.3 o 2 Material, in the soft-packed lithium-ion battery with a silicon-carbon composite material as the negative electrode, the soft-packed lithium-ion battery is subjected to routine capacity separation after being shelved at 45°C, formed by high-temperature fixtures, and sealed twice.

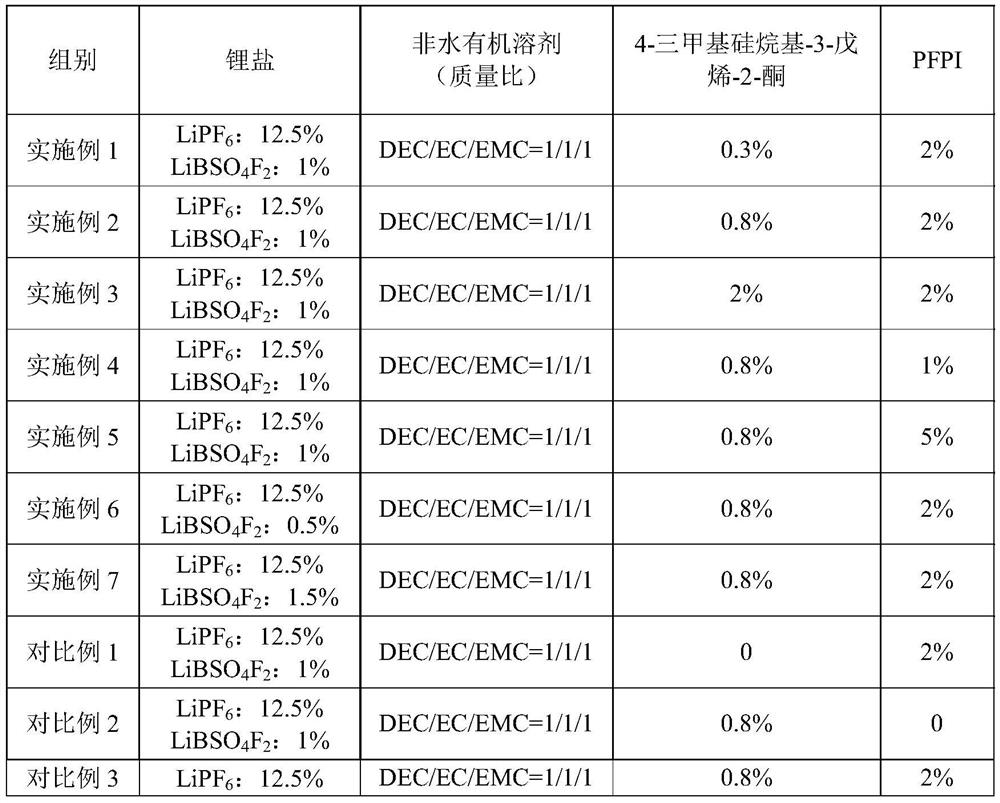

[0021] As shown in Table 1, Examples 2-7 and Comparative Examples 1-3 are the same as Example 1 except that the distribution ratio of each component of the electrolyte is added as shown in Table 1.

[0022] Table 1 The composition and weight percentage distribution of the lithium-ion power battery electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com