Electrolyte adaptive to silicon-carbon negative electrode and lithium ion battery

An electrolyte and negative electrode technology, which is applied in the field of electrolyte and lithium-ion batteries, can solve the problems of destroying the structural stability of positive active materials, the dissolution of positive transition metal ions, and the acceleration of electrolyte decomposition to produce gas, etc., to achieve inhibition of metal ion dissolution, Improve the continuous repair ability and improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

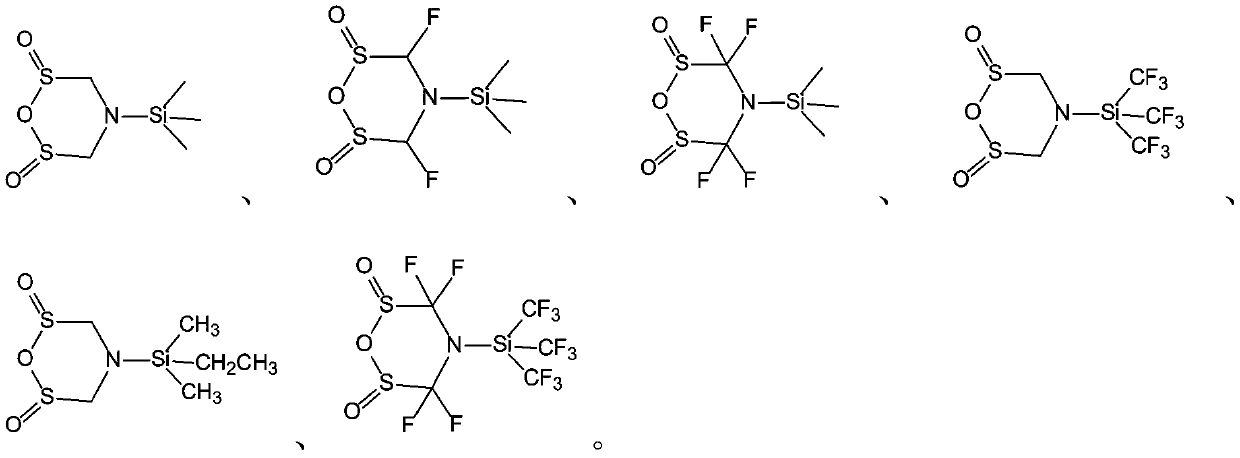

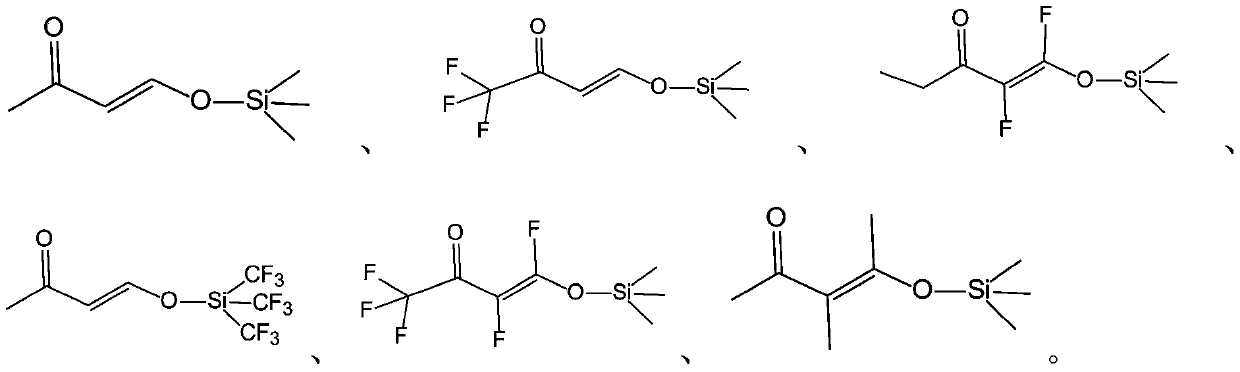

[0034] Preparation of electrolyte: In a glove box filled with argon, ethylene carbonate, ethyl methyl carbonate and diethyl carbonate were mixed in a mass ratio of EC:EMC:DEC=3:2:5, and then added to the mixed solution. Slowly add 13.0 wt% lithium hexafluorophosphate (LiPF) based on the total weight of the electrolyte. 6 ), 0.5 wt % lithium difluorophosphate (LiPO) based on the total weight of the electrolyte 2 F 2 ) and 2.5 wt % lithium bisfluorosulfonimide (LiFSI) based on the total weight of the electrolyte, and finally, 1.0 wt % based on the total weight of the electrolyte of compound A with the structure of formula I, 0.3 wt % of compound A with the structure of formula II Compound B, 10 wt % of fluoroethylene carbonate (FEC) and 0.5 wt % of ethylene sulfate (DTD) were mixed to obtain the electrolyte of Example 1.

[0035] Preparation of soft pack battery: the prepared positive electrode sheet (active material LiCoO 2 ), the diaphragm and the negative electrode sheet (...

Embodiment 2-14

[0036] Examples 2-14 and Comparative Examples 1-9

[0037] In Examples 2-14 and Comparative Examples 1-9, except that the composition ratio of each component of the electrolyte solution is added as shown in Table 1, the rest are the same as those in Example 1. In addition, the structural formula of the additive of formula I and the structural formula of the additive of formula II in each embodiment are shown in Table 2.

[0038] Table 1 embodiment 1-14 and the electrolyte composition ratio of each component of comparative example 1-9

[0039]

[0040]

[0041]

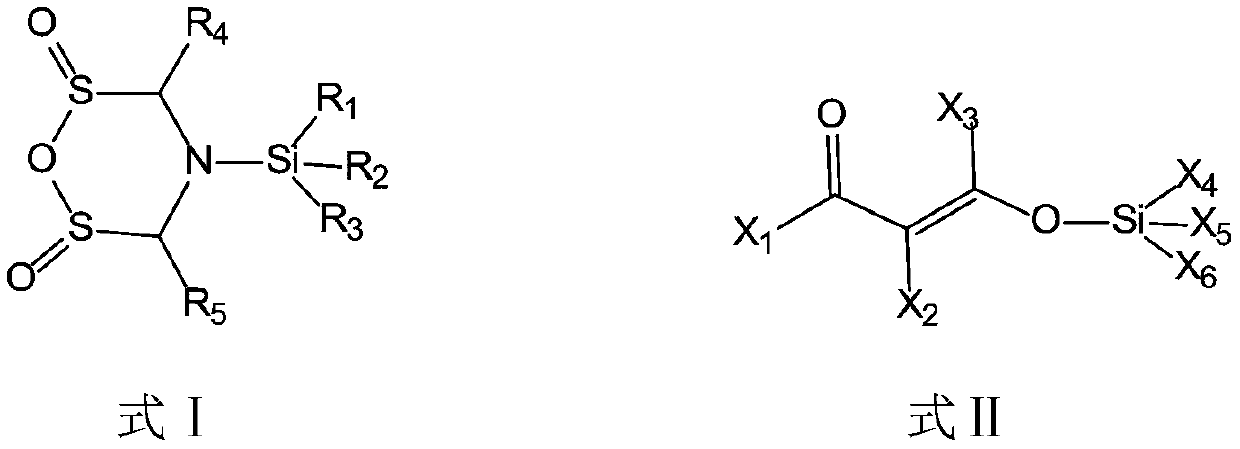

[0042] Structural Formula I and Structural Formula II Specific Substance Descriptions in the Examples of Table 2

[0043]

[0044]

[0045] Performance Testing

[0046] Relevant performance tests were carried out on the batteries prepared in Examples 1-14 and Comparative Examples 1-9 and their electrolytes.

[0047] (1) Normal temperature cycle performance test: At 25°C, the battery after capacity div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com