Carbon-coated carbon nitride nanowires and its preparation method and application of photocatalytic degradation of bisphenol-a

A carbon-coated carbon nitride and carbon nitride-coated technology, which is applied in the field of photocatalytic materials, can solve the problems of wide spectral response, large specific surface area, high photocatalytic activity, and reduced bandgap width, so as to broaden the range of visible light. Effects of absorption range, separation promotion, and high photocatalytic degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

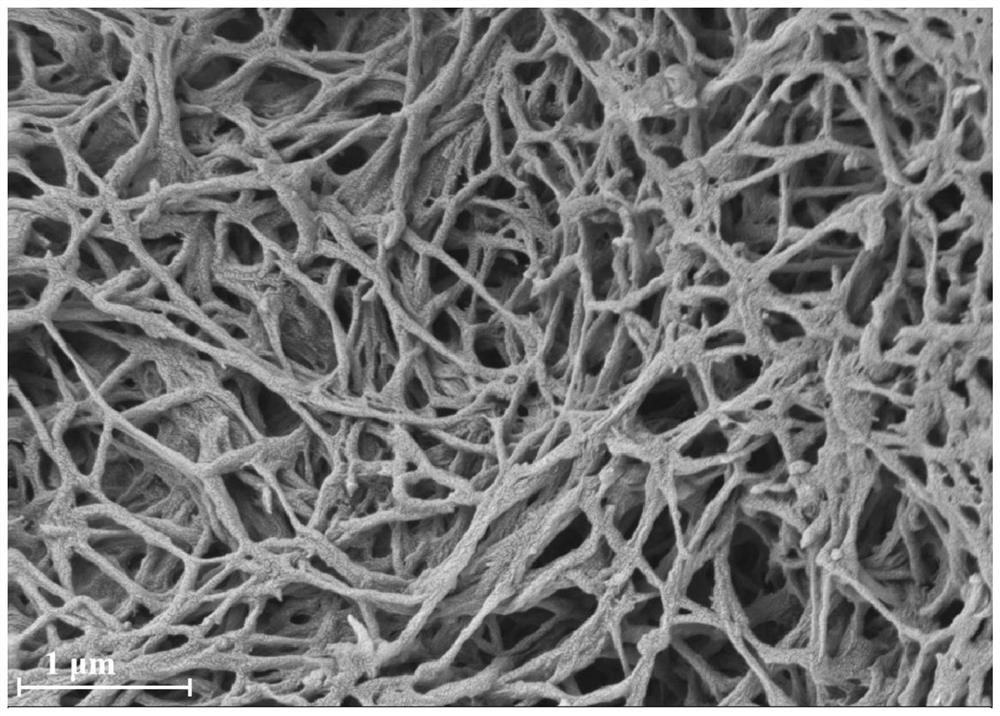

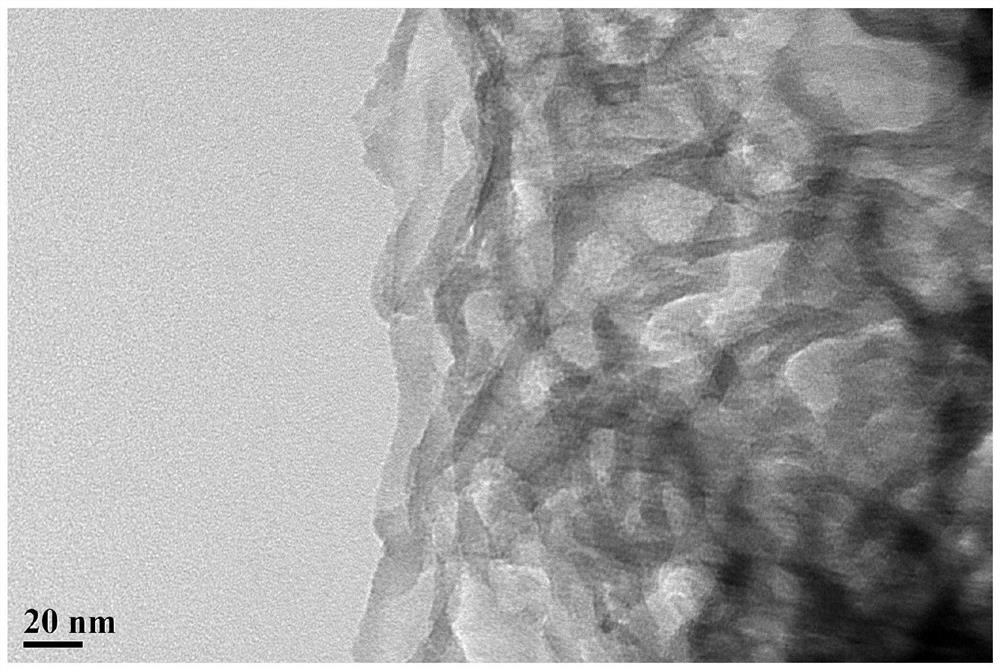

[0050] This embodiment provides a carbon-coated carbon nitride nanowire, the preparation method of which comprises the following steps:

[0051] (1) Add 1 g of polyethylene glycol-polypropylene glycol-polyethylene glycol triblock copolymer into 61 mL of water and stir at a constant temperature of 35 ° C. Under stirring conditions, add 7 mL of 2 mol / L nitric acid dropwise The solution was stirred at a constant temperature of 35°C for 24 hours until the polyethylene glycol-polypropylene glycol-polyethylene glycol was completely dissolved; then 2.5 g of dicyandiamide was added and stirred at a constant temperature of 35°C for 20 hours to obtain a uniform mixed solution;

[0052] (2) Transfer the above mixed solution to a 100mL reaction kettle, conduct a hydrothermal reaction at 80°C for 24h, and after natural cooling, freeze-dry the obtained product for 5d to obtain a carbon-coated carbon nitride nanowire precursor;

[0053] (3) Place the precursor of carbon-coated carbon nitride...

Embodiment 2

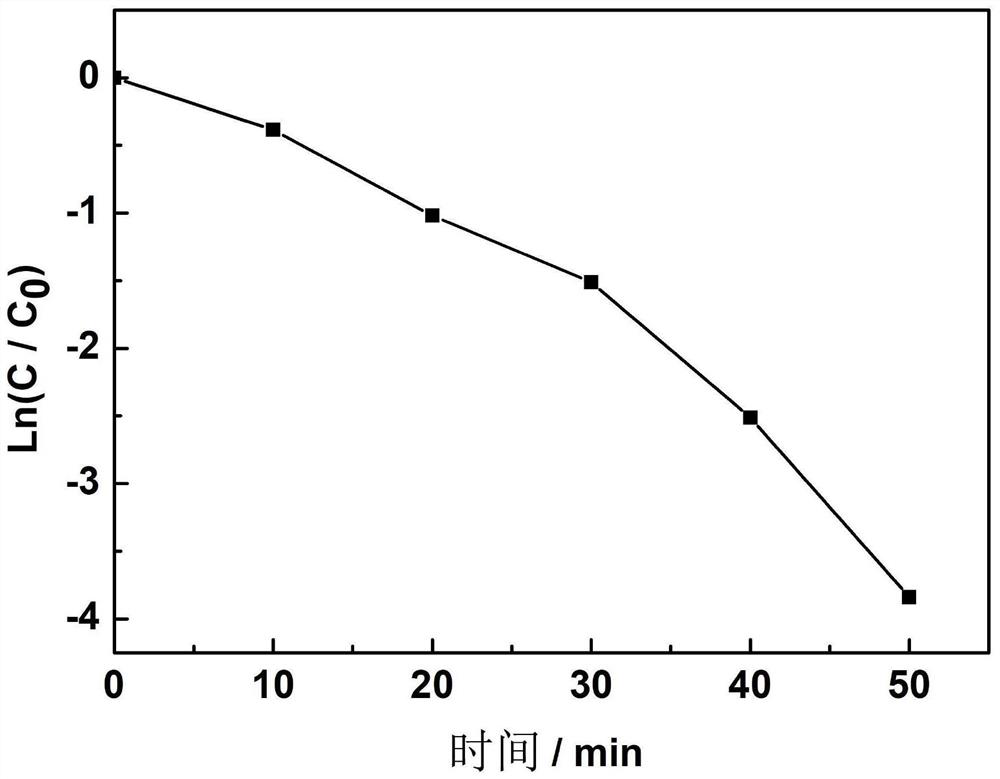

[0056] With bisphenol A as the target pollutant, the carbon-coated carbon nitride nanowire prepared in Example 1 is used as a catalyst to carry out an evaluation experiment of photocatalytic degradation activity. The evaluation experiment is carried out in the following manner:

[0057] Add 10 mg of carbon-coated carbon nitride nanowires to 50 mL of bisphenol A with an initial concentration of 5 ppm. Before the reaction starts, the adsorption is carried out under dark conditions, and the reaction starts after the adsorption equilibrium is reached.

[0058] A 300W Xe lamp is used as a light source, and a (420nm) cut-off filter is installed on it, and the distance between the light source and the reaction liquid surface is 10cm. During the reaction time of 50 minutes, samples were taken every 10 minutes, and the change of the concentration of bisphenol A was detected by high-performance liquid chromatography. During the reaction, the solution was always in a stirring state.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com