Sulfur hexafluoride tail gas recovery device

A technology of tail gas recovery and sulfur hexafluoride, which is applied in the direction of equipment loaded into pressure vessels, gas treatment/storage purposes, gas/liquid distribution and storage, etc. Drift and other issues, to achieve the effect of zero emissions and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

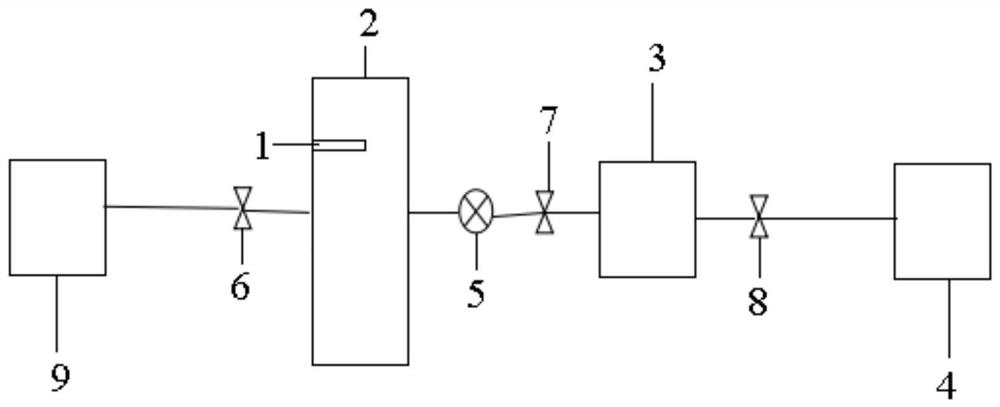

[0012] Specific implementation mode one: this implementation mode is a sulfur hexafluoride tail gas recovery device, such as figure 1 As shown, it is specifically composed of a pressure sensor 1, a gas buffer unit 2, a gas compression unit 3, a gas storage unit 4, a diaphragm pump 5, a first electromagnetic valve 6, a second electromagnetic valve 7, a third electromagnetic valve 8 and a controller ( Not shown) composition;

[0013] The inside of the gas buffer unit 2 is provided with a pressure sensor 1, and the gas inlet of the gas buffer unit 2 communicates with the gas outlet of the detection instrument 9; the pipeline between the gas buffer unit 2 and the detection instrument 9 is provided with a first electromagnetic valve 6 The gas outlet of the gas buffer unit 2 communicates with the air inlet of the gas compression unit 3, a diaphragm pump 5 and a second electromagnetic valve 7 are arranged on the pipeline between the gas buffer unit 2 and the gas compression unit 3, a...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the gas compression unit 3 is a cylinder. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the gas storage unit 4 is a steel cylinder. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com