Battery electrode piece and preparation method thereof

A battery pole piece and pole piece technology, applied in the field of battery pole piece and its preparation, can solve the problems of difficulty in intercalation and extraction of lithium ions, poor electrolyte wettability, poor cycle stability, etc., so as to improve Coulomb efficiency and cycle performance. , Easy to insert and remove, improve the effect of wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

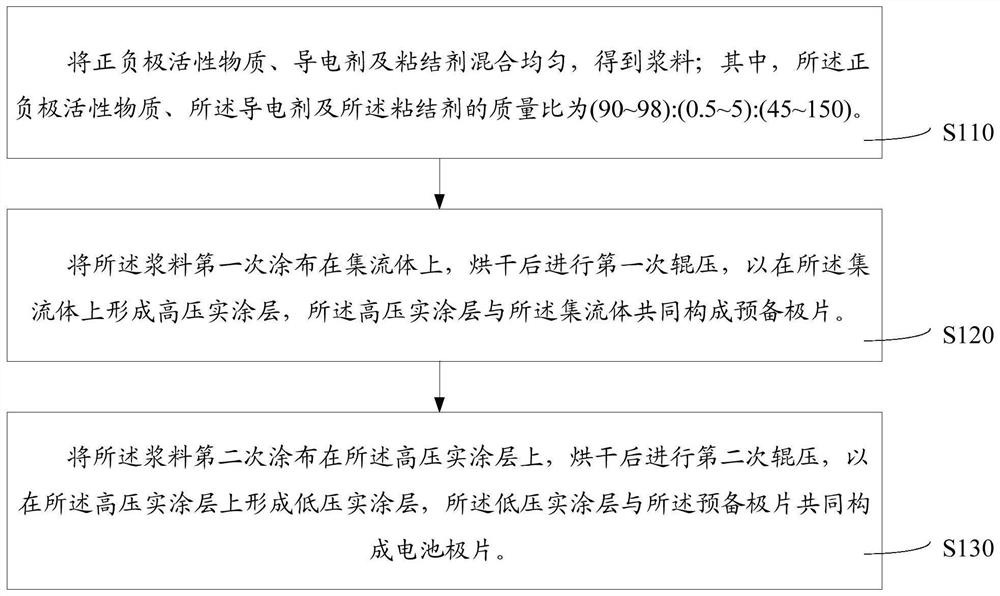

[0029] For an implementation, see figure 1 , a method for preparing a battery pole piece, comprising the following steps:

[0030] S110, uniformly mix the positive / negative active material, conductive agent and binder to obtain a slurry; wherein, the mass ratio of the positive / negative active material, the conductive agent and the binder is (90-98 ):(0.5~5):(45~150).

[0031] It should be noted that the content of positive / negative active materials is related to the energy density of the battery. Increasing the content of positive / negative active materials within a certain range can increase the energy density of the battery, but if the content of positive / negative active materials is too high , it will cause the electrical conductivity and bonding performance of the slurry to drop significantly, and even cause the positive / negative active material to fall off, so the mass ratio of the positive / negative active material, the conductive agent and the binder is preferably (90~9...

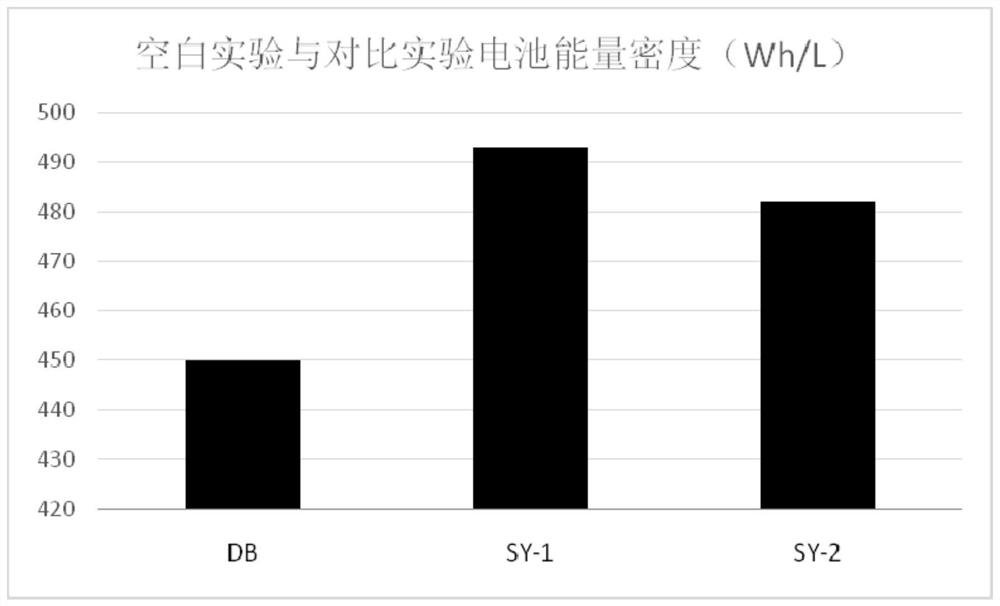

Embodiment 1

[0061] S111, uniformly mix the positive / negative active material, the conductive agent and the binder to obtain a slurry; wherein, the mass ratio of the positive / negative active material, the conductive agent and the binder is (90-98 ):(0.5~5):(45~150). Wherein, the slurry ratio of the positive electrode is LCO:SP:CNT:PVDF=97.6:0.85:0.7:0.85, and the slurry ratio of the negative electrode is C:SP:CMC:SBR=95:2:1.5:1.5.

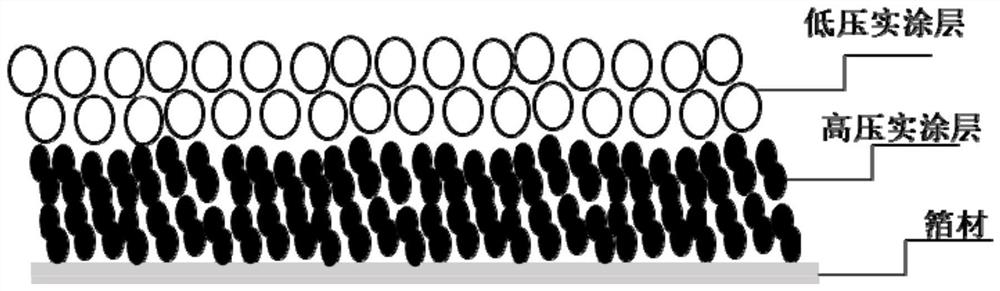

[0062] S121, coating the slurry on the current collector for the first time, and performing the first cold pressing after drying to form a high-compact coating on the current collector, the high-compact coating and the The above-mentioned current collectors together constitute the prepared pole piece.

[0063] S131, coating the slurry on the high-compact coating for the second time, and rolling for the second time after drying to form a low-compact coating on the high-compact coating, The low compaction coating and the preliminary pole piece together constitu...

Embodiment 2

[0065] S112, uniformly mix the positive / negative active material, conductive agent and binder to obtain a slurry; wherein, the mass ratio of the positive / negative active material, the conductive agent and the binder is (90-98 ):(0.5~5):(45~150). Wherein, the slurry ratio of the positive electrode is LCO:SP:CNT:PVDF=97.6:0.85:0.7:0.85, and the slurry ratio of the negative electrode is C:SP:CMC:SBR=95:2:1.5:1.5.

[0066] S122, coating the slurry on the current collector for the first time, and performing the first roll pressing after drying to form a high-compact coating on the current collector, the high-compact coating and the high-compact coating The above-mentioned current collectors together constitute the prepared pole piece.

[0067] S132, coating the slurry on the high-compaction coating for the second time, and rolling for the second time after drying to form a low-compaction coating on the high-compaction coating, The low compaction coating and the preliminary pole p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com