Preparation method increasing the light-emitting core size of indium phosphide quantum dots

An indium quantum and indium phosphide technology, which is applied in the field of preparation of core-shell structure quantum dots, can solve the problems of reducing and decreasing the probability of carrier radiation recombination, and achieves a product suitable for popularization and use, with uniform size distribution and avoiding being easily oxidized. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

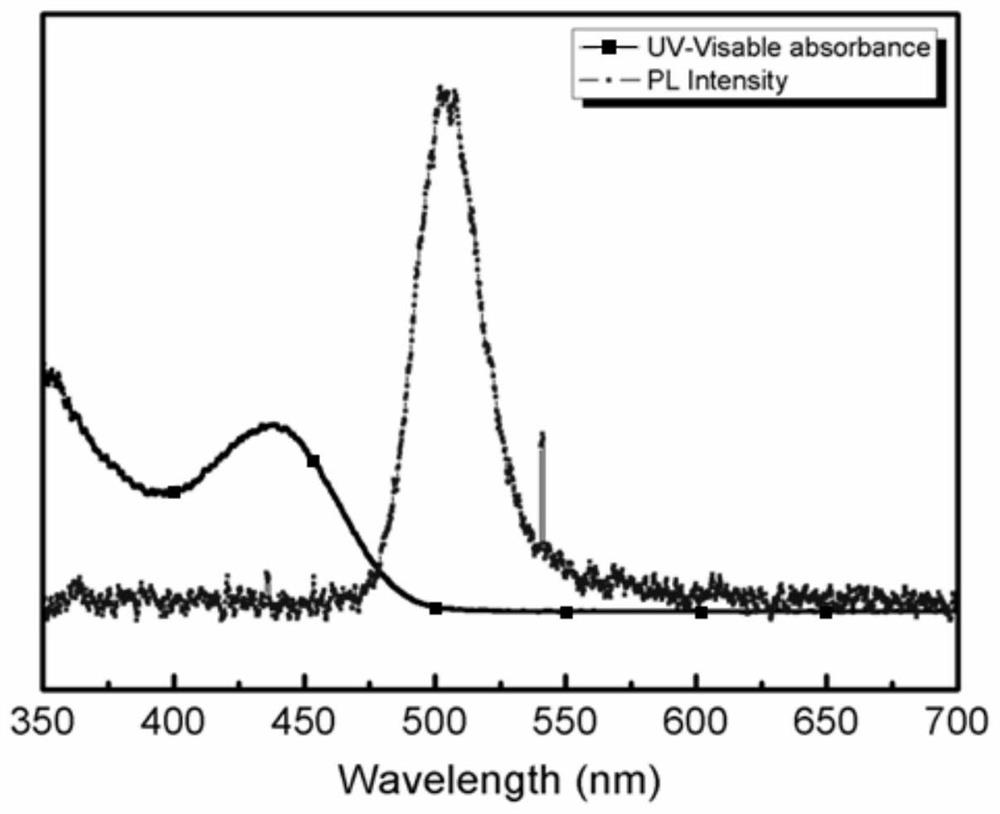

Embodiment 1

[0027] In the present embodiment, a kind of preparation method of indium phosphide (InP) quantum dot, the steps are as follows:

[0028] 1) Preparation of raw materials:

[0029] Prepare a uniform indium precursor solution, and prepare a phosphorus precursor solution for future use. The steps are as follows:

[0030] 1-1) Preparation of selenium-trioctylphosphine (Se-TOP):

[0031] Under a nitrogen environment, the elemental selenium and trioctylphosphine were mixed and dissolved to obtain a Se-TOP solution with a concentration of 2M for subsequent use;

[0032] 1-2) Add 0.15mmol of indium acetate, 0.45mmol of hexadecanic acid and 10ml of octadecene into a three-necked flask, blow in nitrogen and heat to 120°C for 1h to remove water and oxygen to form a uniform indium precursor Body solution, spare;

[0033] 1-3) Prepare a phosphorus precursor solution with 0.1 mmol of tris(trimethylsilyl)phosphine as a phosphorus source, and set aside;

[0034] 2) Preparation of indium ph...

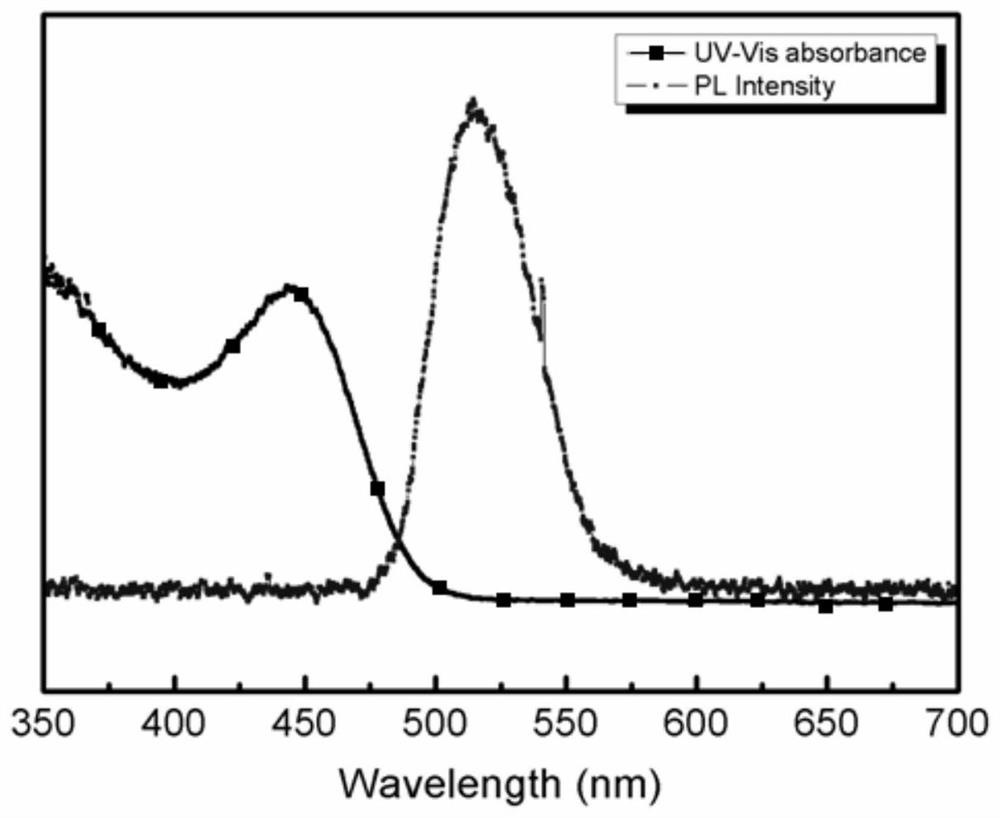

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, especially in that:

[0042] In this embodiment, a preparation method for increasing the size of the indium phosphide quantum dot luminescent core, the steps are as follows:

[0043] 1) This step is the same as Embodiment 1;

[0044] 2) Preparation of indium phosphide nanocrystalline nuclei at low temperature:

[0045] Cool down to the first temperature of 50°C, and at the first temperature, add 0.1 mmol of tris(trimethylsilyl) prepared in step 1) to the indium precursor solution prepared in step 1) 80% of the phosphine, first make nano-clusters grow in the stock solution; then, at the second temperature of 60°C, continue to slowly add the remaining 0.1mmol required for the synthesis of the outer shell to the indium phosphide nanocrystal core product solution 20% of tris(trimethylsilyl) phosphine is incubated for 30 minutes to form an indium phosphide nanocrystal nucleus, thereby obtaining an indium phosphide nano...

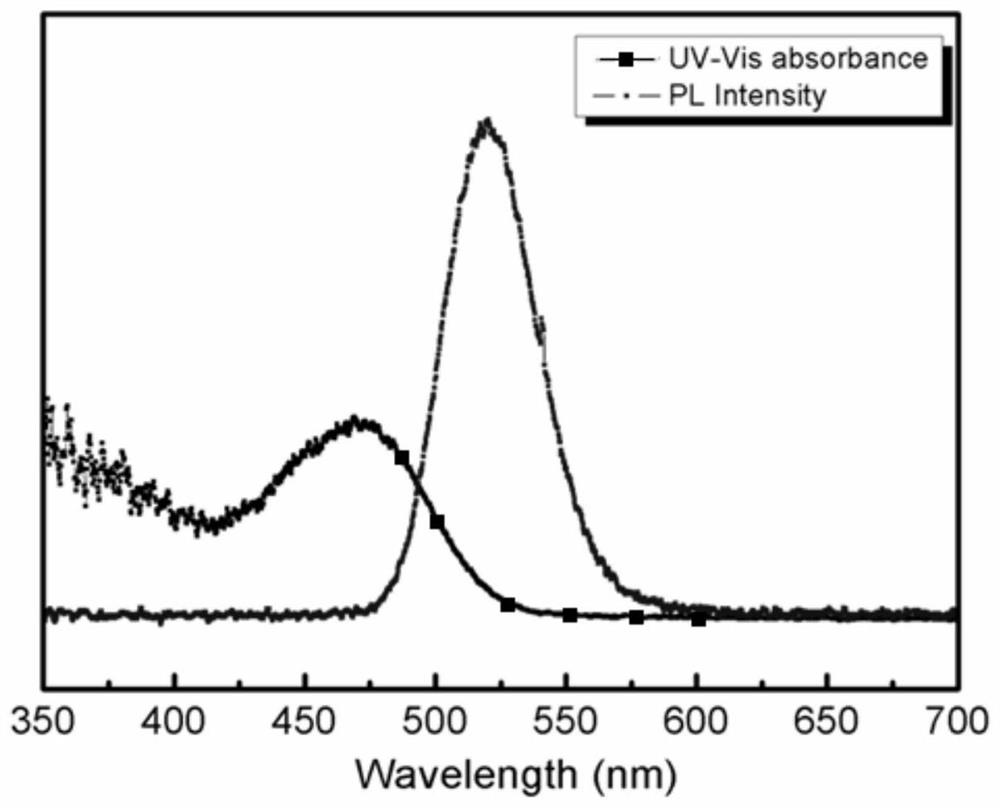

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 1, especially in that:

[0051] In this embodiment, a preparation method for increasing the size of the indium phosphide quantum dot luminescent core, the steps are as follows:

[0052] 1) This step is the same as Embodiment 1;

[0053] 2) Preparation of indium phosphide nanocrystalline nuclei at low temperature:

[0054] Cool down to the first temperature of 50°C, and at the first temperature, add 0.1 mmol of tris(trimethylsilyl) prepared in step 1) to the indium precursor solution prepared in step 1) 60% of the phosphine, first make the nano-clusters grow in the stock solution; then, at the second temperature of 60°C, continue to slowly add the remaining 0.1mmol required for the synthesis of the outer shell to the indium phosphide nanocrystal core product solution 40% of three (trimethylsilyl) phosphine, heat preservation 30min, form indium phosphide nano crystal nucleus, thereby obtain indium phosphide nano crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com