NCMA quaternary gradient material and preparation method thereof

A gradient material and element technology, applied in electrical components, active material electrodes, electrochemical generators, etc., can solve the problems of high production environment requirements and poor cycle performance of high-nickel materials, so as to facilitate industrial production, improve cycle performance, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075]The present invention also provides a preparation method of NCMA quaternary gradient material, preparing the above-mentioned NCMA quaternary gradient material, the method comprising: synthesizing NCMA containing Ni, Co, Mn, Al and a cladding layer containing element Mg The precursor for the quaternary gradient material is post-treated with the lithium salt and the precursor for the NCMA quaternary gradient material to prepare the NCMA quaternary gradient material.

[0076] In some embodiments, the method includes the steps of:

[0077] Dissolving nickel salt, cobalt salt, manganese salt and aluminum salt in water to prepare mixed solution A containing Ni, Co, Mn and Al, and mixed solution B containing Ni, Co, Mn and Al;

[0078] Prepare saturated magnesium salt solution C;

[0079] Making the mixed solution A, the mixed solution B and the magnesium salt solution C react in a reaction vessel to obtain a precursor for the NCMA quaternary gradient material;

[0080] The l...

Embodiment 1

[0102] (1) Nickel sulfate, cobalt sulfate, manganese sulfate, and aluminum sulfate are respectively prepared into a mixed solution A687.5L with a concentration of 2mol / L and Mixed solution B62.5L; prepare saturated magnesium salt solution C with 715g of analytically pure magnesium sulfate; prepare sodium hydroxide solution with a concentration of 8mol / L; prepare ammonia solution with a concentration of 6mol / L.

[0103] (2) Mix solution B with V by metering pump 2 = 0.5L / h speed into the container where the mixed solution A, control the speed of 80r / min and stir slowly to make it evenly mixed, AB mixed solution at a speed of V 1 =6L / h speed into the reactor. Adjust the flow rate of sodium hydroxide solution and ammonia solution, control the pH at about 11.5, the temperature is 50°C, the reaction kettle speed is 800r / min, and the reaction is carried out under the protection of nitrogen.

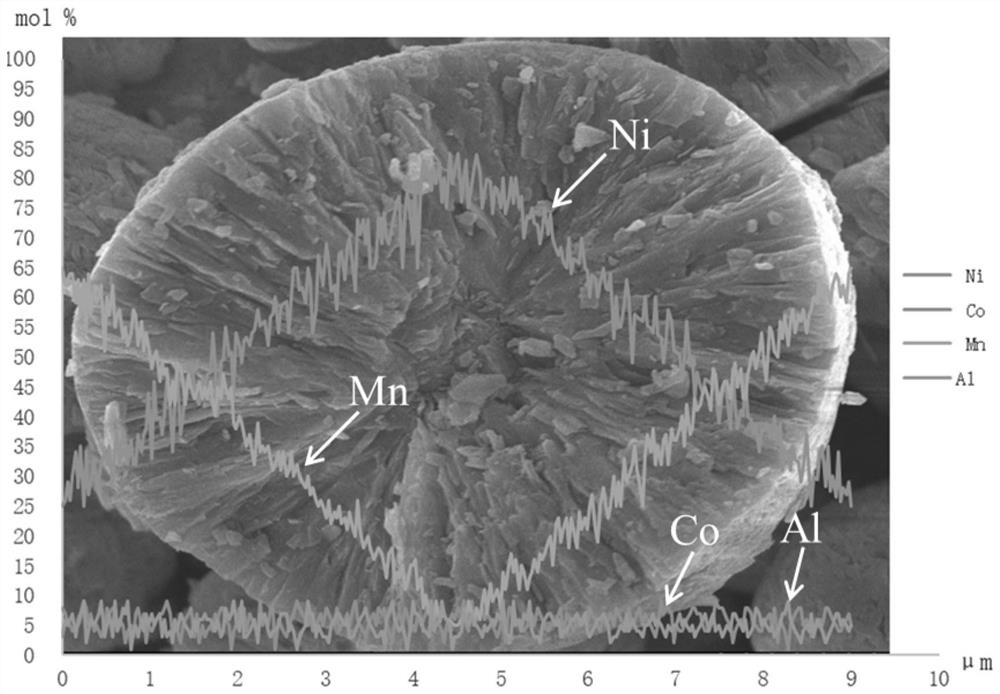

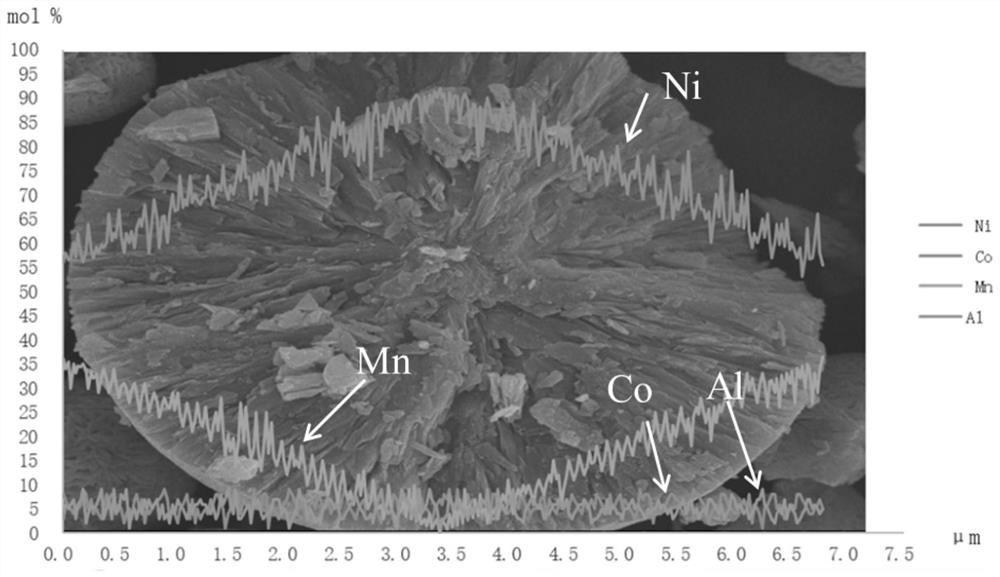

[0104] (3) When the first particle size in the reaction kettle reaches 7 μm, all the magn...

Embodiment 2

[0108](1) Nickel sulfate, cobalt sulfate, manganese sulfate, and aluminum sulfate are respectively prepared into a mixed solution A918L with a concentration of 1.5mol / L according to the molar ratio of 92:3:2:3 and 32:3:62:3 and mixed Solution B162L; prepare saturated magnesium salt solution C with 520g of analytically pure magnesium sulfate; prepare a sodium hydroxide solution with a concentration of 10mol / L; prepare an ammonia solution with a concentration of 8mol / L.

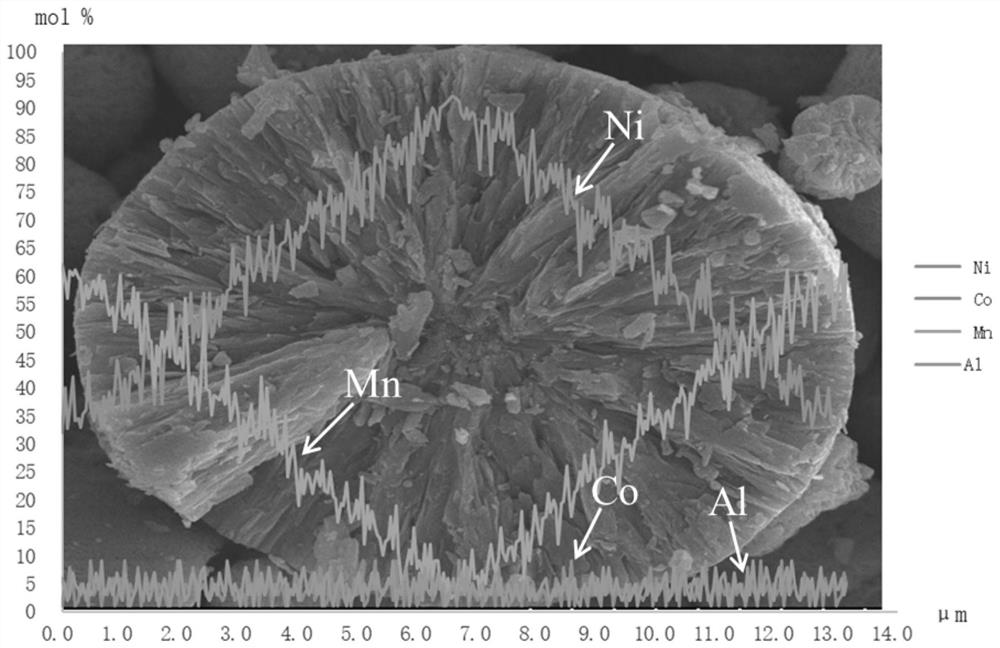

[0109] (2) Mix solution B with V by metering pump 2 Pour into the container where the mixed solution A is located at a speed of =0.9L / h, control the speed of 80r / min and stir slowly to make it evenly mixed, and the AB mixed solution is mixed at a speed of V 1 =6L / h speed into the reactor. Adjust the flow rate of sodium hydroxide solution and ammonia solution, control the pH at about 12.0, the temperature is 60°C, the reaction kettle speed is 900r / min, and the reaction is carried out under the protection of nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com