Film bulk acoustic resonator and preparation method thereof

A thin-film bulk acoustic wave and thin-film acoustic wave technology, which is applied in the field of thin-film bulk acoustic resonators and its preparation, can solve the problems of complex structure, instability, and low quality factor of production process of thin-film bulk acoustic resonators, and achieve reduced parasitic effects and smooth ripples , Optimize the effect of the parallel resonance point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present invention provides a preferred embodiment, a thin film bulk acoustic resonator, which has a simple and stable structure, and at the same time, the damage to the core components of the thin film bulk acoustic resonator is small during the manufacturing process, and the introduction of parasitic capacitance can be avoided , the quality factor of the thin film bulk acoustic resonator is greatly improved, and the manufacturing cost of the thin film bulk acoustic wave resonator is reduced at the same time.

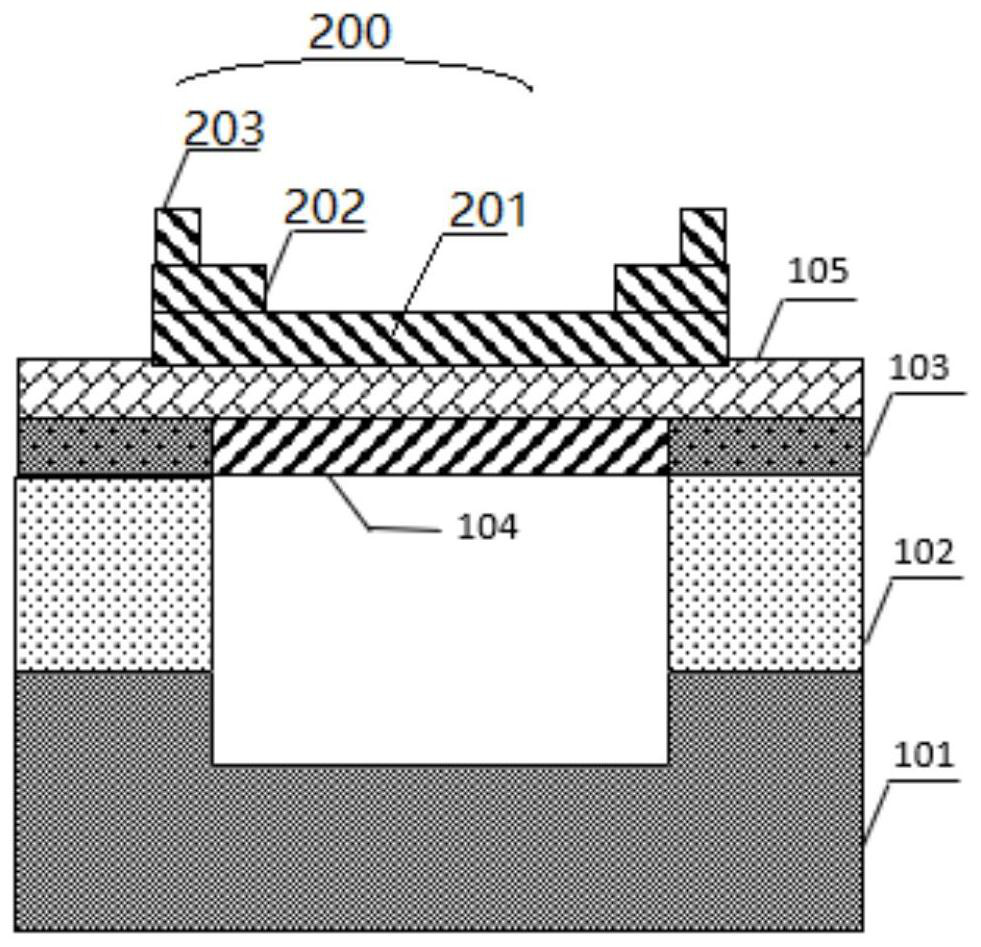

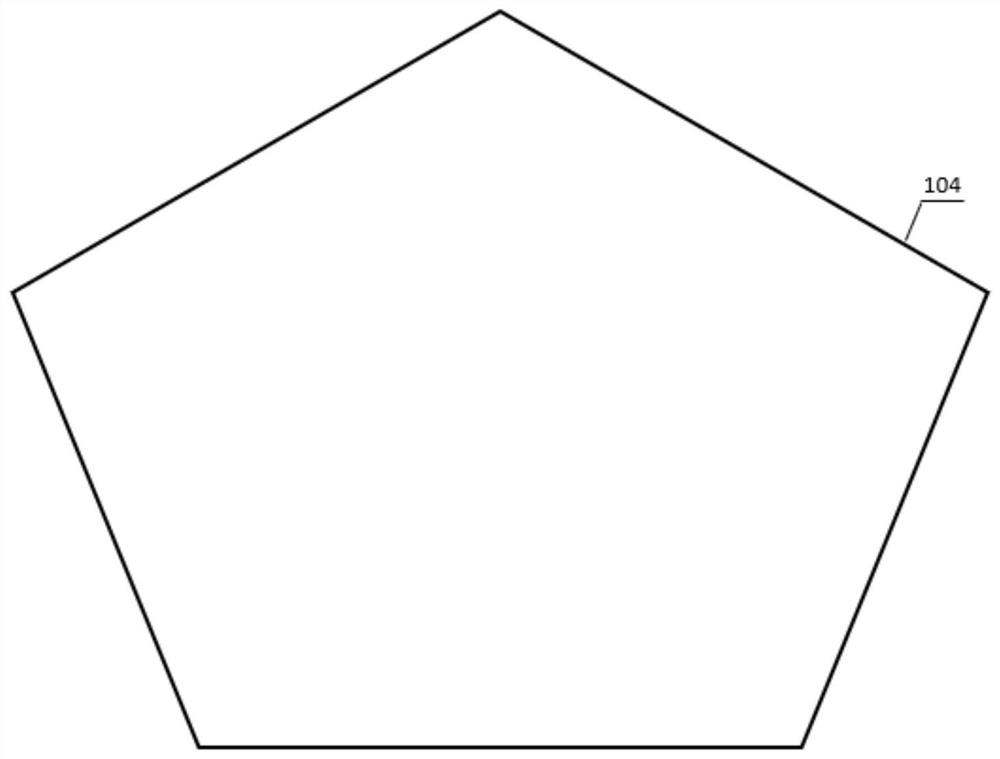

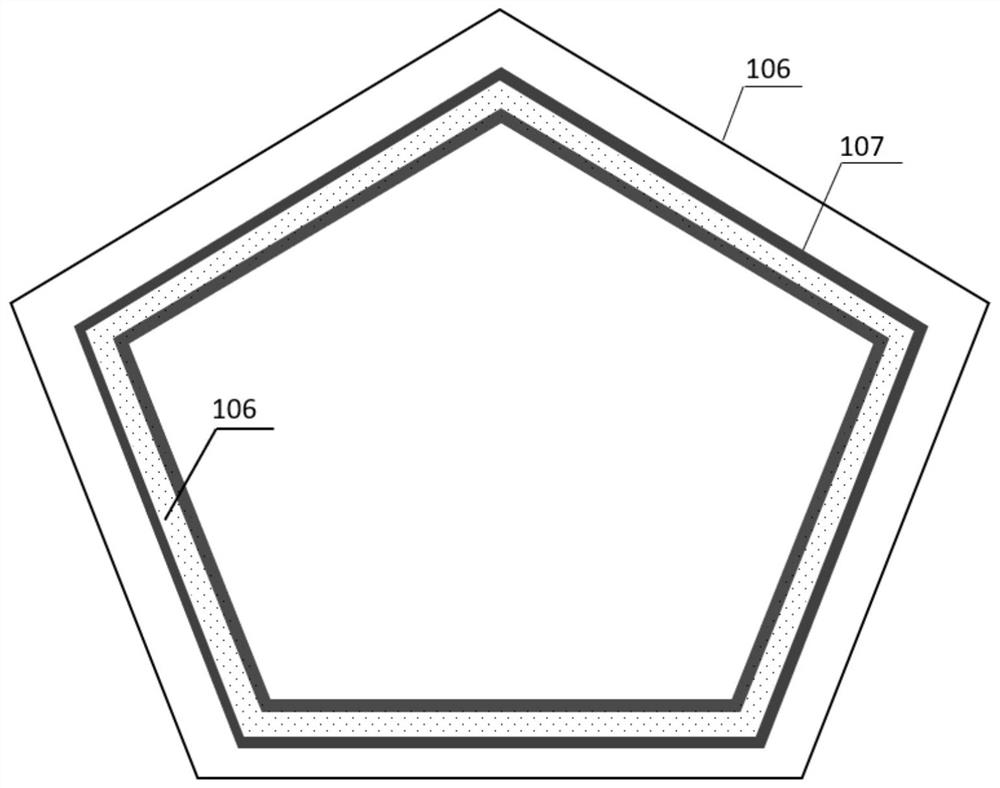

[0039] Such as figure 1 As shown, a thin film bulk acoustic resonator includes a transfer substrate 101 , a bonding layer 102 , a filling layer 103 , a bottom electrode 104 , a piezoelectric film 105 and a top electrode 200 distributed sequentially from bottom to top.

[0040] Wherein, the top electrode 200 is located above the piezoelectric film 105 , and the bottom electrode 104 is located below the piezoelectric film 105 . In this way, a sandwich structur...

Embodiment 2

[0062] Based on Embodiment 1, the present invention also provides a method for preparing a thin film acoustic wave resonator, which specifically includes the following steps:

[0063] In step S1, a single crystal silicon wafer is selected as an epitaxial substrate, and a piezoelectric thin film is grown on the epitaxial substrate.

[0064] Preferably, growing a layer of piezoelectric film on the epitaxial substrate can use physical vapor deposition (PVD, PhysicalVapor Deposition), metal organic chemical vapor deposition (MOCVD, metal organic chemical vapordeposition) and pulsed laser deposition (PLD, Pulsed Laser Deposition) and any one or more methods to grow a piezoelectric thin film on the epitaxial substrate.

[0065] Step S2, growing a bottom electrode on the first surface of the piezoelectric film, and obtaining the shape of the bottom electrode by etching.

[0066] Preferably, magnetron sputtering is used to form the bottom electrode on the first surface of the piezoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com