Manganese ferrite @ carbon nitride composite material as well as preparation method and application thereof

A composite material and carbon nitride technology, applied in the field of materials, can solve the problem of low specific capacitance of carbon materials, and achieve the effects of improving electrochemical performance, excellent cycle stability, and non-toxic and harmless solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

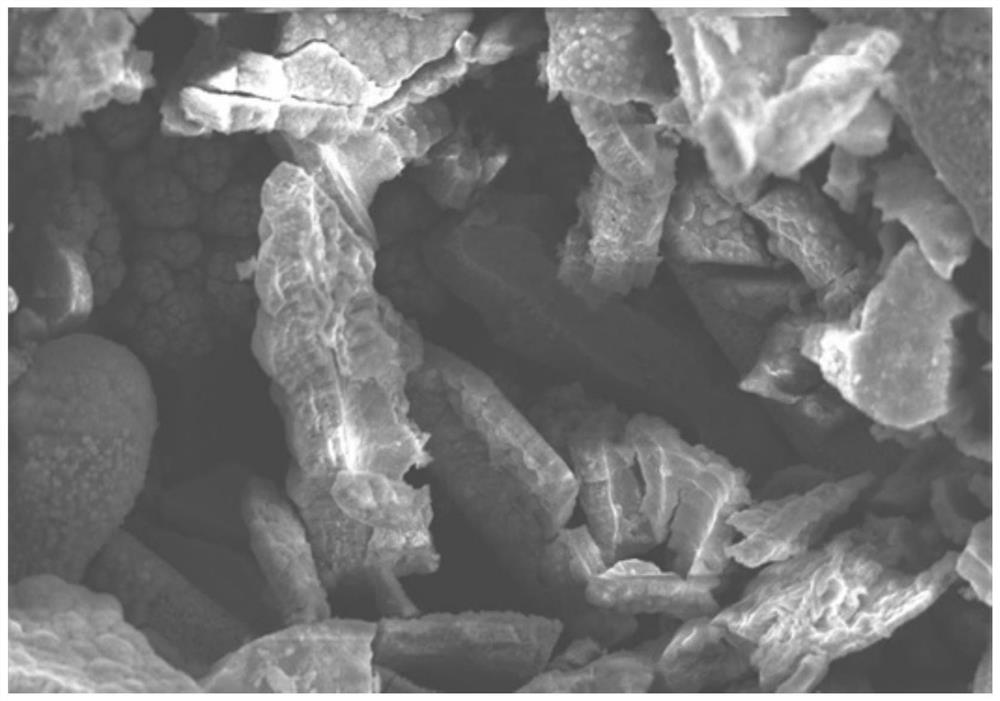

[0036] A MnFe 2 o 4 @Carbon Nitride Composite Material, the shape of the composite material is rod-like, and it is prepared by the following steps:

[0037] In the first step, put 8g CO(NH 2 ) 2 , and then sealed and placed in a tube furnace for high-temperature calcination, the temperature of high-temperature calcination is 400°C, the time of high-temperature calcination is 4h, and the heating rate is 5°C min -1 ;

[0038] In the second step, put the sample prepared in the first step into a beaker, and use concentrated nitric acid and concentrated sulfuric acid to acidify the sample for 1 hour, then wash with deionized water, centrifuge at 10000r / min for 15 minutes, and vacuum dry at 60°C 12h;

[0039] In the third step, the sample processed in the second step is transferred to the autoclave, and then 30 mL of NH with a concentration of 25% by mass is added. 3 ·H 2 O, then carry out hydrothermal reaction, the temperature of hydrothermal reaction in the process is 180 ℃, ...

Embodiment 2

[0043] A MnFe 2 o 4 @Carbon Nitride Composite Material, the shape of the composite material is rod-like, and it is prepared by the following steps:

[0044] In the first step, put 8g CO(NH 2 ) 2 , and then sealed and placed in a tube furnace for high-temperature calcination, the temperature for high-temperature calcination is 600°C, the time for high-temperature calcination is 4 hours, and the heating rate is 5°C min -1 ;

[0045] In the second step, take the sample prepared in the first step and put it into a beaker, use concentrated nitric acid and concentrated sulfuric acid to acidify the sample for 1 hour, then wash with deionized water, centrifuge at 10000r / min for 15 minutes, and vacuum dry at 60°C for 12 hours ;

[0046] In the third step, the sample processed in the second step is transferred to the autoclave, and then 30 mL of NH with a concentration of 25% by mass is added. 3 ·H 2 O, then carry out hydrothermal reaction, the temperature of hydrothermal reactio...

Embodiment 3

[0050] A MnFe 2 o 4 @Carbon Nitride Composite Material, the shape of the composite material is rod-like, and it is prepared by the following steps:

[0051] In the first step, put 8g CO(NH 2 ) 2 , and then sealed and placed in a tube furnace for high-temperature calcination, the temperature of high-temperature calcination is 600°C, the time of high-temperature calcination is 8 hours, and the heating rate is 5°C min -1 ;

[0052] In the second step, take the sample prepared in the first step and put it into a beaker, use concentrated nitric acid and concentrated sulfuric acid to acidify the sample for 1 hour, then wash with deionized water, centrifuge at 10000r / min for 15 minutes, and vacuum dry at 60°C for 12 hours ;

[0053] In the third step, the sample processed in the second step is transferred to the autoclave, and then 30 mL of NH with a concentration of 28% by mass is added. 3 ·H 2 O, then carry out hydrothermal reaction, the temperature of hydrothermal reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com