Polymer thermal activation delayed fluorescence material ink for ink-jet printing, preparation method thereof and ink-jet printing method

A heat-activated delay and inkjet printing technology, applied in the direction of copying/marking method, application, printing, etc., can solve the problem of uneven film thickness, etc., achieve the effect of improving film forming quality, reducing solvent residue, and overcoming coffee ring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Weigh 2.5 milligrams of P-Ac95-TRZ05 and place it in a container, then weigh 0.6 milliliters of cyclohexanone and add it to the container to form a mixed solution, then weigh 0.2 milliliters of cumene and 0.2 milliliters of cyclohexylbenzene, Put into the above mixed solution, wherein the first solvent content is 61.0%, the second solvent content is 18.3%, the third solvent content is 20.4%, and the solute content is 0.3%. After stirring at room temperature and completely dissolving, the polymer thermally activated delayed fluorescent material ink for inkjet printing is obtained.

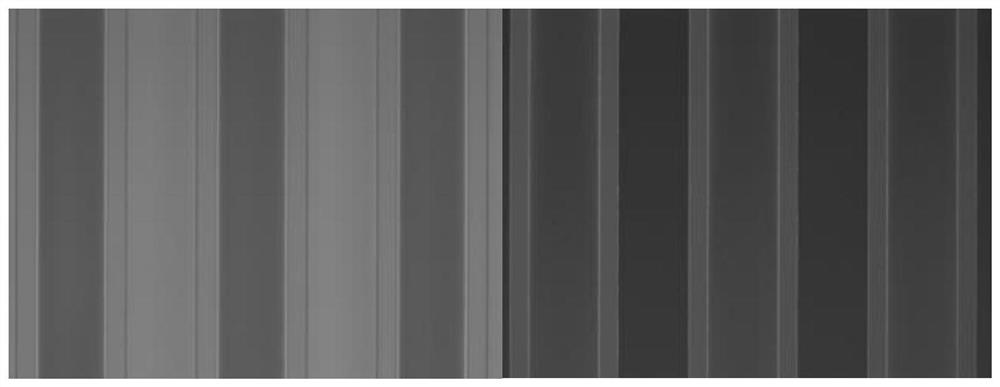

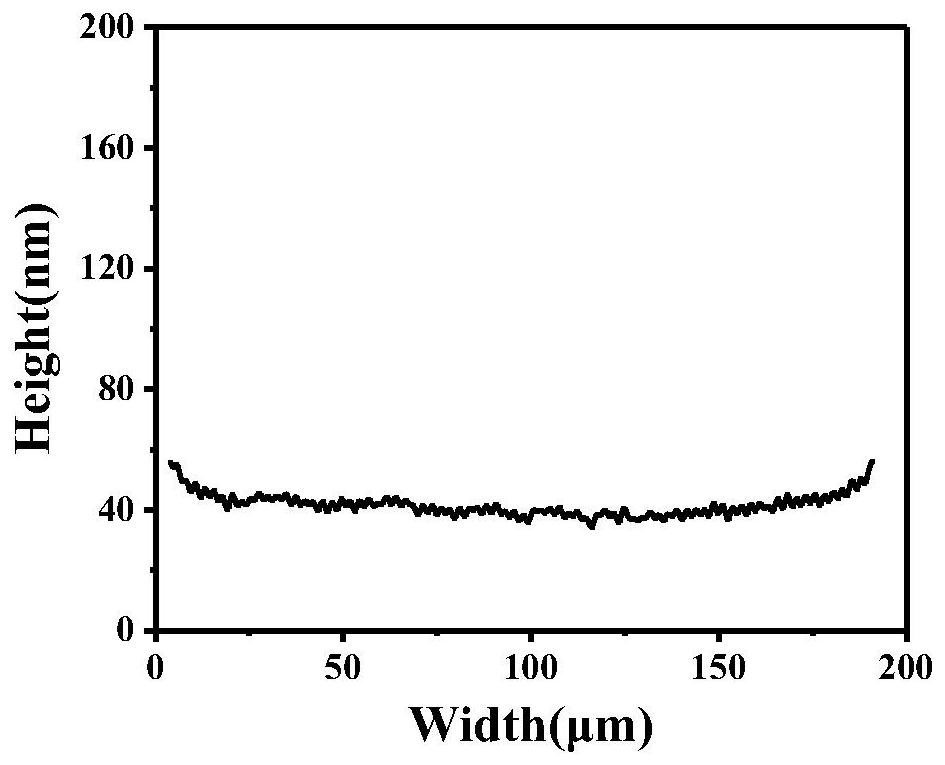

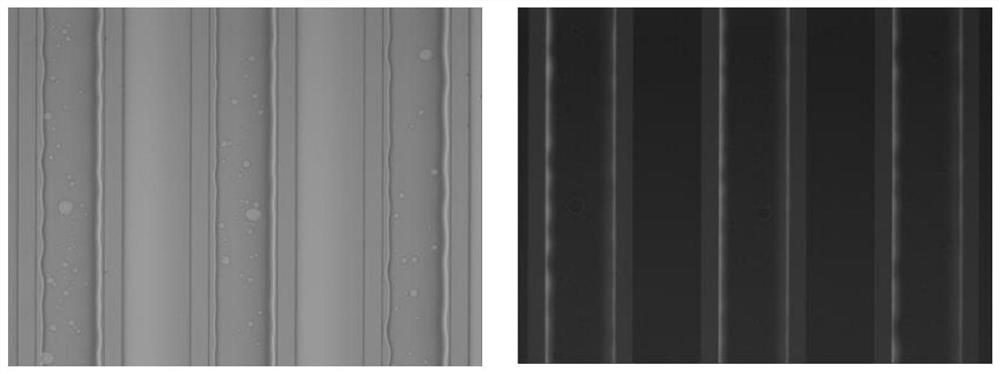

[0051] figure 1 Be that the P-Ac95-TRZ05 ink jet printing that embodiment 1 prepares is deposited in the optical microscope image of the P-Ac95-TRZ05 thin film in the restriction channel (the left figure is an optical microscope image, and the right figure is a fluorescence microscope image), figure 2 It is the cross-sectional height map of the P-Ac95-TRZ05 film deposited in the restriction...

Embodiment 2

[0053] Weigh 2.5 mg of P-Ac95-TRZ05 and place it in a container, then weigh 0.5 ml of chlorobenzene and add it to the container to form a mixed solution, then weigh 0.3 ml of cumene and 0.2 ml of cyclohexylbenzene, put In the above mixed solution, the first solvent content is 55.1%, the second solvent content is 25.8%, the third solvent content is 18.9%, and the solute content is 0.2%. After stirring at room temperature and completely dissolving, a polymer heat-activated delayed fluorescent material ink suitable for inkjet printing and capable of improving the uniformity of the printed film is obtained.

Embodiment 3

[0055] Weigh 3 mg of P-Ac95-TRZ05 and place it in a container, then weigh 0.5 milliliters of o-xylene and add it to the container to form a mixed solution, then weigh 0.3 milliliters of isopropyltoluene and 0.2 milliliters of chloronaphthalene, put into the above mixed solution, wherein the first solvent content is 46.9%, the second solvent content is 27.3%, the third solvent content is 25.5%, and the solute content is 0.3%. After being stirred at room temperature and completely dissolved, an organic small molecule light-emitting material ink suitable for inkjet printing and capable of improving the uniformity of the printed film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com