Deplating process for ABS plastic surface plating layer

An ABS plastic and coating technology, which is applied in the field of ABS plastic surface coating stripping process, can solve the problems of long process time, long time required, and less processing capacity for plastic stripping, and achieves low stripping cost and good adsorption capacity. , the effect of fast adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

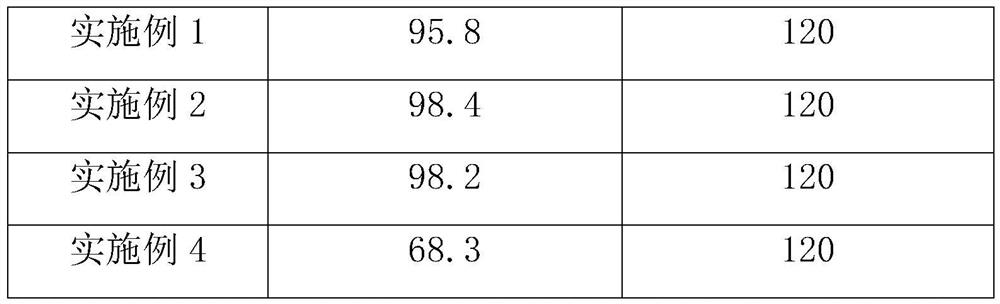

Embodiment 1

[0028] Carboxylation of nano-graphite: Weigh 12kg of nano-graphite and place it in the reaction chamber of the plasma equipment, and evacuate the reaction chamber to 2×10 -4 Pa, then heated to 100°C, and nitrogen gas was introduced into the reaction chamber until the gas pressure in the reaction chamber reached 2Pa, the radio frequency power was turned on, and the reaction was performed for 10 minutes under the conditions of the reaction power of the radio frequency power supply of 500W and the frequency of the radio frequency power supply of 400KHz. After the reaction was completed, Take out the nano-graphite, then disperse the nano-graphite in 900kg of ether solution, then add 8kg of succinic anhydride, react at a constant temperature of 25°C for 2h, suction filter to obtain a solid powder, transfer the solid powder into a constant temperature box at 45°C Dry under vacuum for 3 hours to obtain carboxylated nano-graphite.

[0029] Preparation of modified chitosan: Take chitos...

Embodiment 2

[0037] Carboxylation of nano-graphite: Weigh 14kg of nano-graphite and place it in the reaction chamber of the plasma equipment, and evacuate the reaction chamber to 1.8×10 -3 Pa, then heated to 200°C, and nitrogen gas was introduced into the reaction chamber until the gas pressure in the reaction chamber reached 2.5Pa, the radio frequency power supply was turned on, and the reaction power was 1000W at the radio frequency power supply, and the radio frequency power supply frequency was 450MHz. , take out the nano-graphite, and then disperse the nano-graphite in 900kg of ether solution, then add 10kg of succinic anhydride, react at a constant temperature of 25°C for 2h, obtain a solid powder by suction filtration, transfer the solid powder into a constant temperature box at 45 It was dried under vacuum for 3.5 hours at °C to obtain carboxylated nano-graphite.

[0038] Preparation of modified chitosan: Take chitosan and dissolve it in acetic acid solution, add span-80 and stir f...

Embodiment 3

[0046] Carboxylation of nano-graphite: Weigh 16kg of nano-graphite and place it in the reaction chamber of the plasma equipment, and evacuate the reaction chamber to 3×10 -3 Pa, then heated to 300°C, and nitrogen was introduced into the reaction chamber until the gas pressure in the reaction chamber reached 3Pa, the radio frequency power supply was turned on, and the reaction power was 1500W and the frequency of the radio frequency power supply was 500KHz. The reaction was 20min. After the reaction was completed, Take out the nano-graphite, then disperse the nano-graphite in 900kg of ether solution, then add 12kg of succinic anhydride, react at a constant temperature of 25°C for 2h, and obtain a solid powder by suction filtration, transfer the solid powder into a constant temperature box at 45°C Dry under vacuum for 4h to obtain carboxylated nano-graphite.

[0047] Preparation of modified chitosan: Take chitosan and dissolve it in acetic acid solution, add span-80 and stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com