Intelligent permanent magnet zero-leakage pump

A non-leakage, intelligent technology, applied in the direction of pumps, pump devices, pump components, etc., to achieve the effect of improving work efficiency, improving safety, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

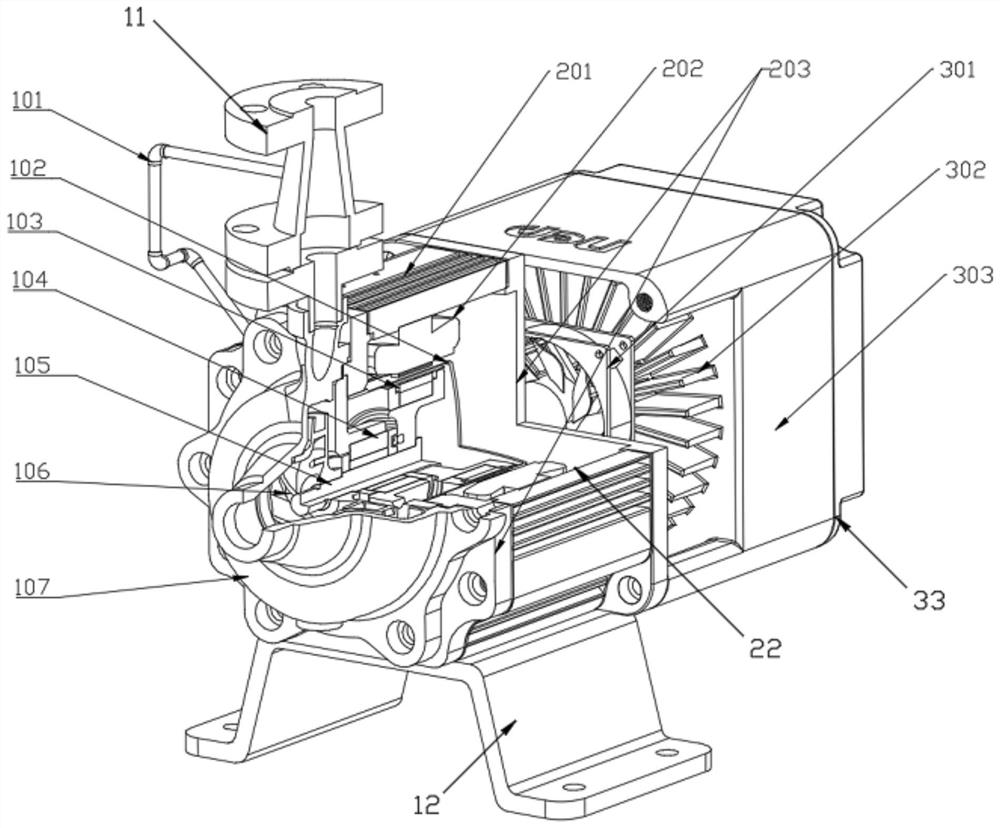

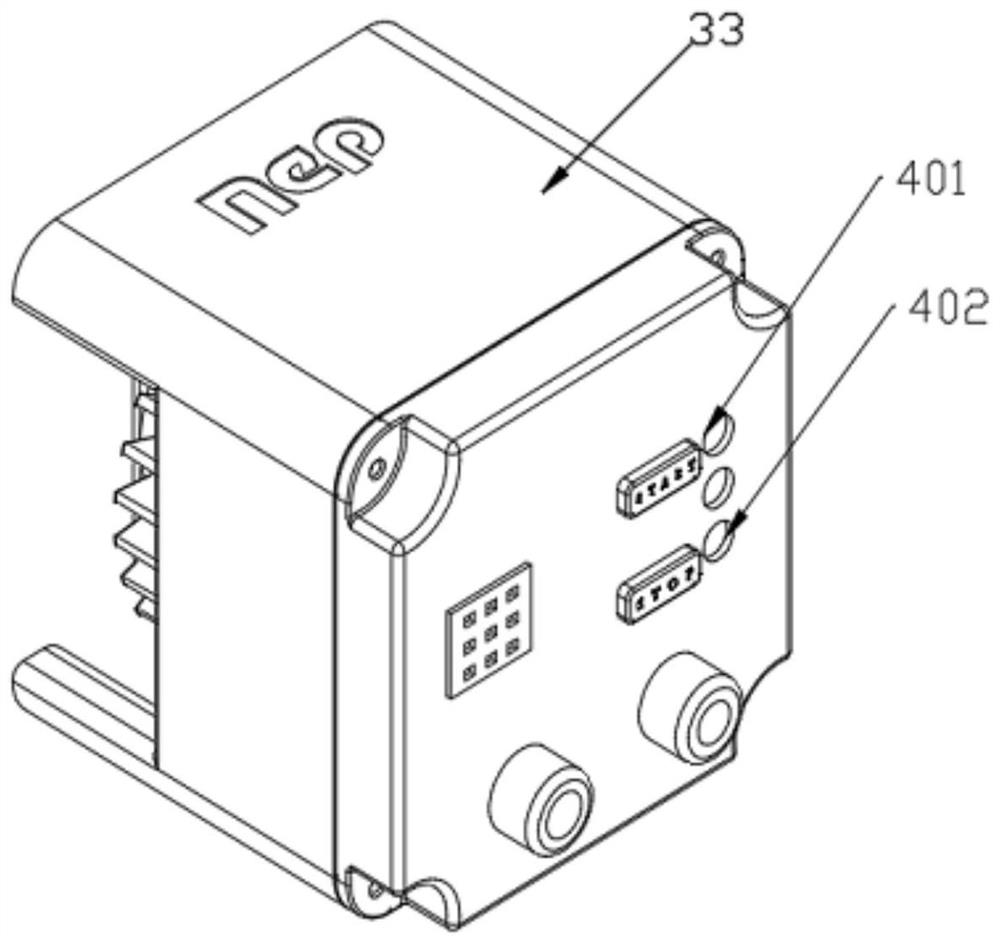

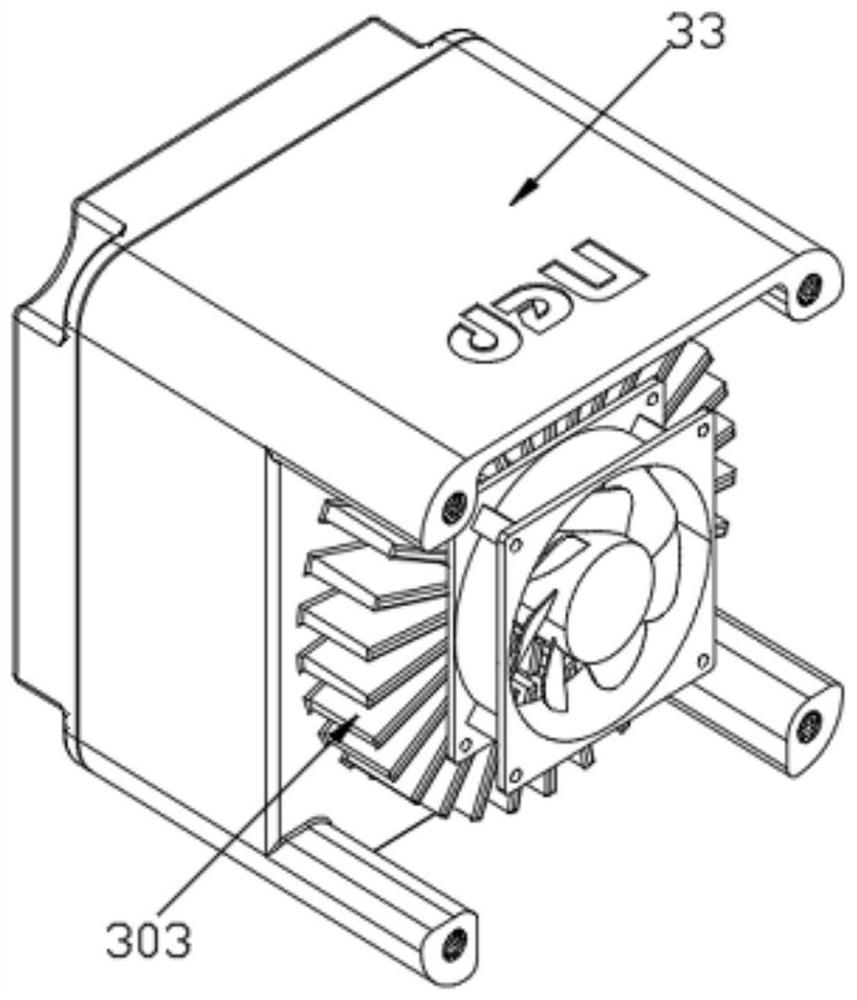

[0031] An intelligent permanent magnet non-leakage pump, such as Figure 1-Figure 3 As shown, it includes a non-leakage pump body 11, a base 12 is installed on the bottom of the non-leakage pump body 11, a permanent magnet synchronous motor stator 22 and an intelligent frequency conversion controller 33 are installed in the non-leakage pump body 11, the non-leakage pump body 11, the permanent The stator 22 of the magnetic synchronous motor and the intelligent frequency conversion controller 33 are connected by a flange assembly 203. The leak-free pump body 11 includes a flow radiator 101, an isolation sleeve 102, a synchronous rotor 103, a bearing 104, a rotating shaft 105, an impeller 106, And the pump housing 107, the permanent magnet synchronous motor stator 22 includes a cooling housing 201 and a stator 202 embedded with three-phase coils, the intelligent frequency conversion controller 33 includes a control box 303, and a cooling fan 301 and some cooling fins are installed...

Embodiment 2

[0041] In the present embodiment, the permanent magnet non-leakage pump of the present invention is compared with the asynchronous frequency conversion magnetic pump, which is as follows:

[0042] 1. Test time: March 25, 2020

[0043] 2. Test location: Hydraulic test workshop of Special Pump Technology Branch of Hunan Naipu Pump Co., Ltd.

[0044] 3. Purpose of the test: Two kinds of motor technical schemes and products are used to drive the same type of non-leakage pump. From the actual test performance data, the current, power, temperature, vibration, noise, etc.

[0045] 4. Test instruments: electrical parameter meter, hand-held clamp ammeter, flow meter, pressure gauge, noise meter, vibration meter, hand-held temperature gun

[0046] 5. Description of test motor and pump status:

[0047] (1) Asynchronous motor 1# refers to asynchronous motor + frequency converter + magnetic coupling

[0048] (2) Asynchronous motor 2# refers to asynchronous motor + frequency converter + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com