Zinc ferrite/Bi-MOF/tannic acid composite visible-light-induced photocatalyst

A technology of zinc ferrite and tannic acid, which is applied in the fields of environment and energy, can solve problems such as poor stability, and achieve the effects of promoting separation, enhancing stability, and strengthening synergistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

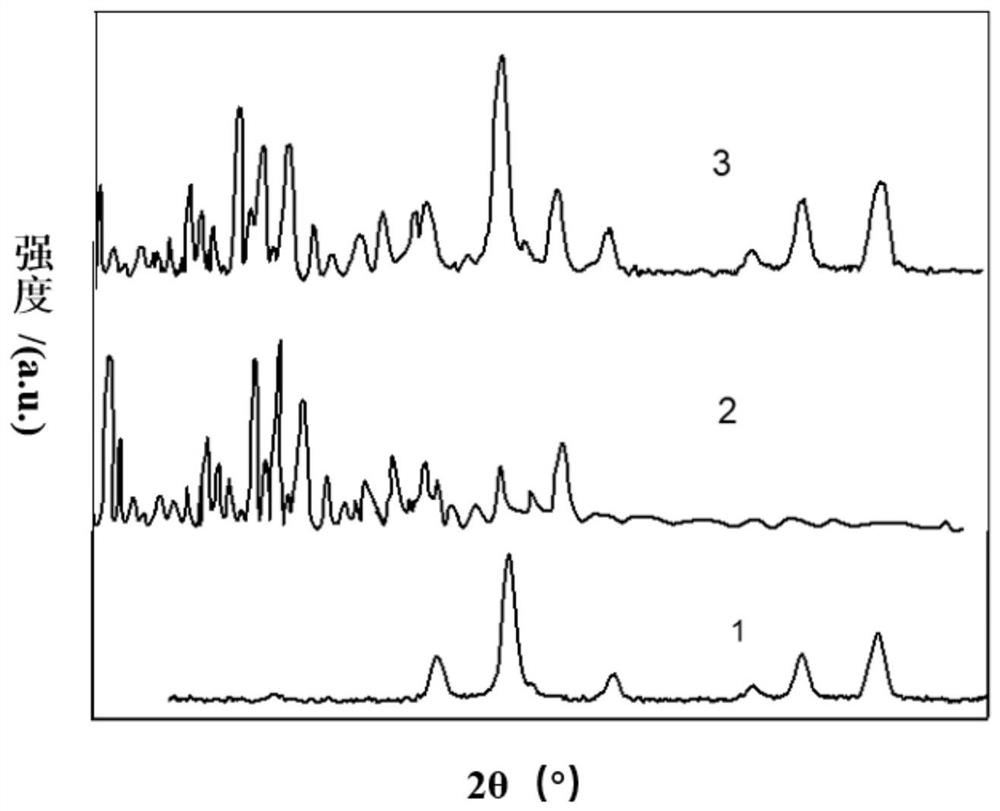

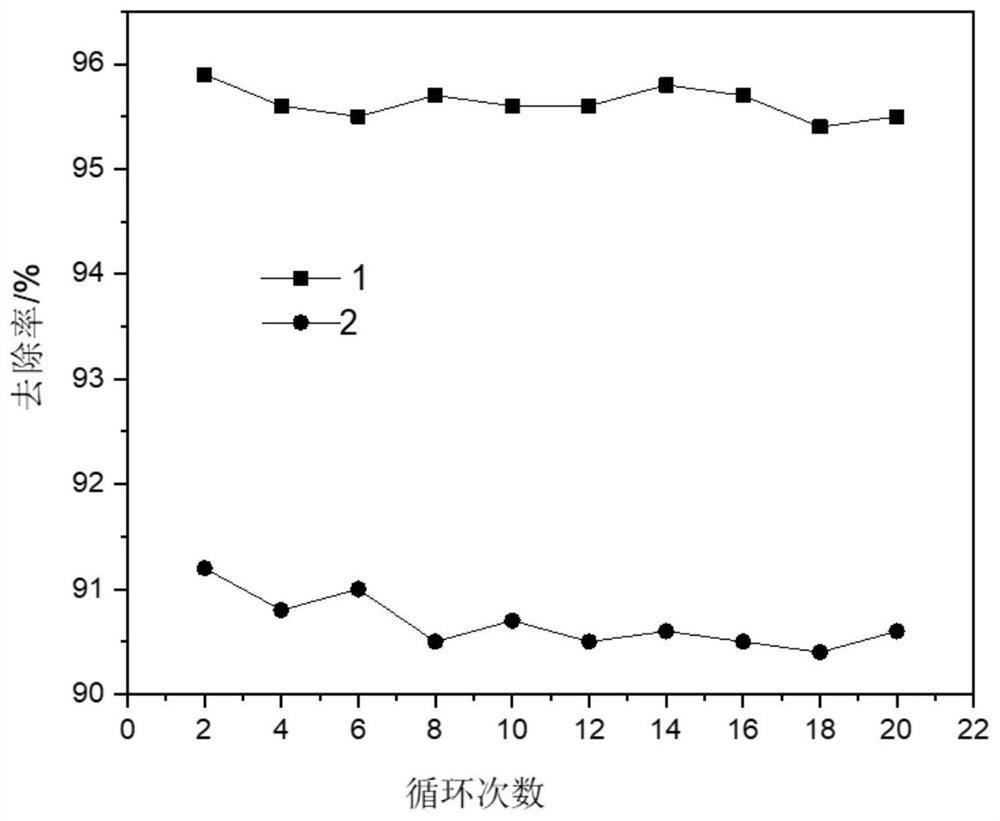

Embodiment 1

[0038] 1. Preparation of zinc ferrite / Bi-MOF / tannic acid composite visible light catalyst:

[0039] Preparation of mixed solvent: Mix dimethylformamide, dipropylene glycol, ethanol, and methanol to prepare a mixed solvent, wherein the mass ratio of dimethylformamide: dipropylene glycol: ethanol: methanol is 1:1:1:2.

[0040] Get 1g bismuth nitrate pentahydrate and 0.6g1,3,5-trimellitic acid and dissolve in 25g of mixed solvent respectively, obtain bismuth nitrate solution and 1,3,5-trimellitic acid solution, put the gained bismuth nitrate solution at room temperature Slowly add it dropwise to the obtained 1,3,5-tribenzenetricarboxylic acid solution while stirring, and continue to stir at room temperature for 0.5h. Then, 0.03 g of tannic acid and 0.3 g of nano-zinc ferrite were added thereto, and stirring was continued at room temperature for 0.5 h to obtain a mixed solution. Among them, the mass ratio of tannic acid: 1,3,5-trimesic acid: bismuth nitrate pentahydrate: nanomete...

Embodiment 2

[0046] 1. Preparation of zinc ferrite / Bi-MOF / tannic acid composite visible light catalyst:

[0047] Prepare mixed solvent: the same as the mixed solvent in Example 1;

[0048] Get 1g bismuth nitrate pentahydrate and 0.9g 1,3,5-trimellitic acid and dissolve in the mixed solvent of 40g respectively, obtain bismuth nitrate solution and 1,3,5-trimellitic acid solution, the gained bismuth nitrate solution Slowly add it dropwise to the obtained 1,3,5-trimesic acid solution while stirring at room temperature, continue to stir at room temperature for 1.0 h, then add 0.18 g of tannic acid and 1.2 g of nano-zinc ferrite to it, and continue to stir at room temperature for 1.0 h. h, to obtain a mixed solution, wherein the mass ratio of tannic acid: 1,3,5-trimellitic acid: bismuth nitrate pentahydrate: nanometer zinc ferrite: mixed solvent is 0.18:0.9:1:1.2:80.

[0049] Put the mixed solution in a hydrothermal reaction kettle. After the reaction kettle is sealed, place it in an electric c...

Embodiment 3

[0054] 1. Preparation of zinc ferrite / Bi-MOF / tannic acid composite visible light catalyst:

[0055] Prepare mixed solvent: the same as the mixed solvent in Example 1;

[0056] Get 1g bismuth nitrate pentahydrate and 0.7g 1,3,5-trimellitic acid and dissolve in the mixed solvent of 30g respectively, obtain bismuth nitrate solution and 1,3,5-trimellitic acid solution, the gained bismuth nitrate solution Slowly add it dropwise to the obtained 1,3,5-trimesic acid solution while stirring at room temperature, continue to stir at room temperature for 0.7h, then add 0.08g of tannic acid and 0.5g of nano-zinc ferrite to it, and continue to stir at room temperature for 0.8 h, to obtain a mixed solution, wherein the mass ratio of tannic acid: 1,3,5-trimellitic acid: bismuth nitrate pentahydrate: nanometer zinc ferrite: mixed solvent is 0.08:0.7:1:0.5:60.

[0057] The mixed solution was placed in a hydrothermal reaction kettle, and after the reaction kettle was sealed, it was placed in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com