Separating method for gold and copper floating bulk concentrate

A technology for mixing concentrates and separation methods, applied in flotation, solid separation, magnetic separation, etc., can solve the problems of high toxicity of chemicals, environmental pollution, and high production costs, and achieve the effect of stable indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

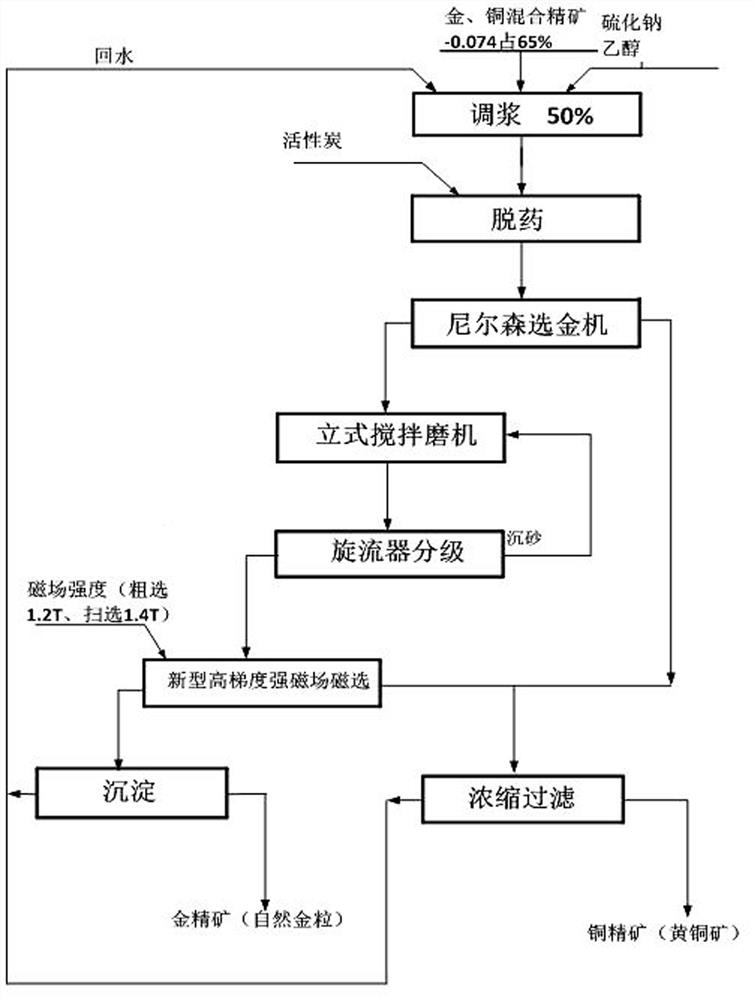

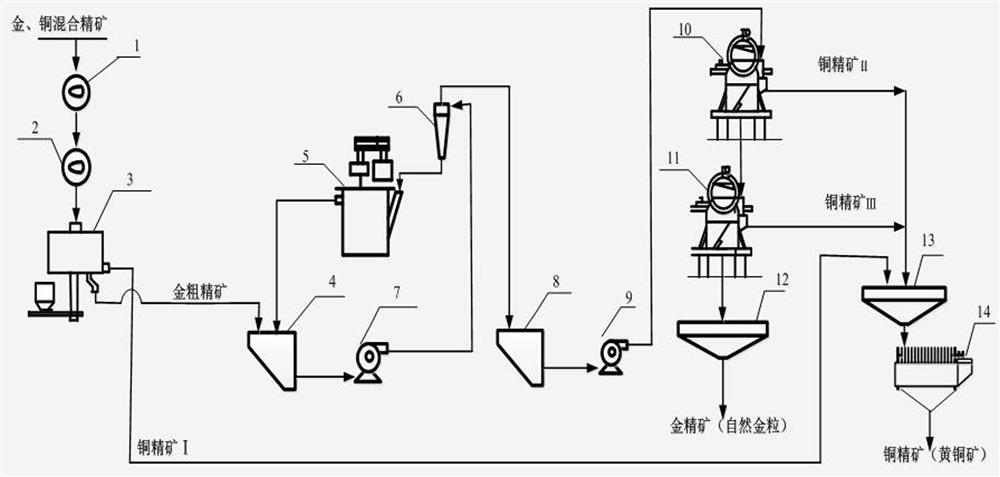

Method used

Image

Examples

Embodiment 1

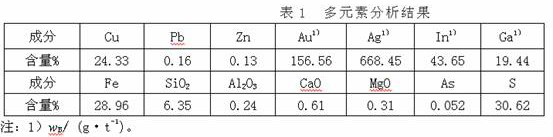

[0044] A gold and copper flotation mixed concentrate mainly includes chalcopyrite, and a small amount of bornite, pyrite, arsenopyrite, native gold, silver-gold ore, argentite, etc.; the non-metallic minerals contained are mainly quartz and Dolomite, followed by calcite and kaolinite. Most of the copper minerals are chalcopyrite, and there is a small amount of bornite. Chalcopyrite mainly exists in the form of monomer, and secondly, it is associated with gangue, and occasionally it can be seen associated with gold and pyrite. Gold exists as free monomer natural gold, accounting for 80.25% of the total gold, and the gold that is dispersed in copper minerals and pyrite as gold joints accounts for 13.50% and 4.20% of the total gold respectively; gold in gangue Accounting for 2.05% of the total gold. Its multi-element analysis is shown in Table 1

[0045]

[0046] Adopt the present invention to implement this gold, copper flotation mixed concentrate, concrete steps are as fol...

Embodiment 2

[0060] A gold and copper flotation mixed concentrate mainly includes chalcopyrite, and a small amount of bornite, pyrite, arsenopyrite, native gold, silver-gold ore, argentite, etc.; the non-metallic minerals contained are mainly quartz and Dolomite, followed by calcite and kaolinite. Most of the copper minerals are chalcopyrite, and there is a small amount of bornite. Chalcopyrite mainly exists in the form of monomer, and secondly, it is associated with gangue, and occasionally it can be seen associated with gold and pyrite. Gold exists as free monomer natural gold, accounting for 80.25% of the total gold, and the gold that is dispersed in copper minerals and pyrite as gold joints accounts for 13.50% and 4.20% of the total gold respectively; gold in gangue Accounting for 2.05% of the total gold. Its multi-element analysis is shown in Table 1

[0061]

[0062] Adopt the present invention to implement this gold, copper flotation mixed concentrate, concrete steps are as fol...

Embodiment 3

[0076] A gold and copper flotation mixed concentrate mainly includes chalcopyrite, and a small amount of bornite, pyrite, arsenopyrite, native gold, silver-gold ore, argentite, etc.; the non-metallic minerals contained are mainly quartz and Dolomite, followed by calcite and kaolinite. Most of the copper minerals are chalcopyrite, and there is a small amount of bornite. Chalcopyrite mainly exists in the form of monomer, and secondly, it is associated with gangue, and occasionally it can be seen associated with gold and pyrite. Gold exists as free monomer natural gold, accounting for 80.25% of the total gold, and the gold that is dispersed in copper minerals and pyrite as gold joints accounts for 13.50% and 4.20% of the total gold respectively; gold in gangue Accounting for 2.05% of the total gold. Its multi-element analysis is shown in Table 1

[0077]

[0078] Adopt the present invention to implement this gold, copper flotation mixed concentrate, concrete steps are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com