Residual oil treatment method for recovering sterol

A treatment method and a technology for recovering sterols, applied in chemical instruments and methods, steroids, organic chemistry, etc., can solve the problems of sodium salts having no practical value, imperfect treatment methods, environmental pollution, etc., and achieve value gain and operation Simple and feasible, high comprehensive benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

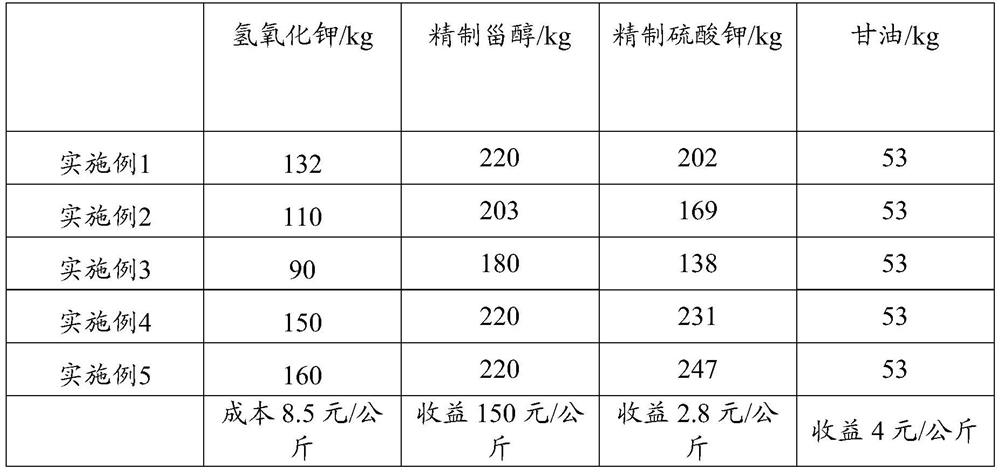

Embodiment 1

[0045] A residual oil processing method for recovering sterols and refining potassium salt, including the following steps:

[0046] (1) Take 132 kg of potassium hydroxide and 1500 kg of anhydrous methanol (content 99.9%) in a 5 ton reaction kettle and heat to 65°C, reflux for 4 hours to react to obtain a mixed solution, and cool to 50°C;

[0047] (2) Put 1800 kg of residual oil (sterol ester content 12%, glyceride 2.5%) into the mixed solution, heat to 80°C, and perform transesterification reaction for 4 hours to obtain transesterified products;

[0048] (3) The transesterification product is acidified, and 160 kg of concentrated sulfuric acid with a concentration of 98% is added with stirring, and after standing for 1 hour, the upper oil phase and the lower water phase are separated to obtain;

[0049] (4) The upper oil phase is washed with hot water at 80°C for 3 times (500kg each time, the water washing liquid and the second upper oil phase are obtained after standing and separated)...

Embodiment 2

[0055] A residual oil processing method for recovering sterols and refining potassium salt, including the following steps:

[0056] (1) Take 110kg of potassium hydroxide and 1500kg of anhydrous methanol (content 99.9%) in a 5 ton reaction kettle and heat to 65°C, reflux for 4h to react to obtain a mixed solution, and cool to 50°C;

[0057] (2) Put 1800 kg of residual oil (sterol ester content 12%, glyceride 2.5%) into the mixed solution, heat to 85°C, and perform transesterification reaction for 4 hours to obtain transesterified products;

[0058] (3) The transesterification product is acidified, and 160 kg of concentrated sulfuric acid with a concentration of 98% is added with stirring, and after standing for 1 hour, the upper oil phase and the lower water phase are separated to obtain;

[0059] (4) The upper oil phase is washed with hot water at 85°C for 3 times (500kg each time, the water washing liquid and the second upper oil phase are obtained after standing and separated). The p...

Embodiment 3

[0065] A residual oil treatment method for recovering sterols and refining potassium salt, including the following steps:

[0066] (1) Take 90 kg of potassium hydroxide and 1500 kg of anhydrous methanol (content 99.9%) in a 5 ton reaction kettle and heat to 70°C, reflux for 5 hours to react to obtain a mixed solution, and cool to 50°C;

[0067] (2) Put 1800 kg of residual oil (sterol ester content 12%, glyceride 2.5%) into the mixed solution, heat to 85°C, and perform transesterification reaction for 3.5 hours to obtain transesterified products;

[0068] (3) The transesterification product is acidified, and 160 kg of concentrated sulfuric acid with a concentration of 98% is added with stirring, and after standing for 1 hour, the upper oil phase and the lower water phase are separated to obtain;

[0069] (4) The upper oil phase is washed with hot water at 80°C for 3 times (500kg each time, the water washing liquid and the second upper oil phase are obtained after standing and separated)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com