A fine temporary plugging volume fracturing technology instead of mechanical packing

A volume fracturing and mechanical isolation technology, applied in the direction of sealing/isolation, production fluid, drilling composition, etc., can solve the problem of insufficient delamination reconstruction of a single mechanical packer, fracturing construction and operation control Problems such as high risk, perforation and interlayer condition constraints have achieved the effect of improving the economic benefits of fracturing, reducing the number of segmented tools, and improving the production degree of the longitudinal section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation of embodiment 1 interstitial plugging agent

[0062] Composition of raw materials (parts by weight): 3 parts of expanded polyvinyl alcohol, 2 parts of sodium peroxide, 1 part of sodium bicarbonate, 2 parts of sodium borate, 1 part of slow-release microcapsule breaker (the content is ammonium persulfate), 25 parts of sulfonated tannin extract, 10 parts of montmorillonite powder and 15 parts of isopropanol.

[0063] Expanded polyvinyl alcohol is prepared from the following raw materials: 10 parts of polyvinyl acetate resin, 5 parts of sodium carboxymethylcellulose, 20 parts of ethanol, 0.5 parts of NaOH, 0.5 parts of acetic acid, and 1 part of barium chloride.

[0064] Expanded polyvinyl alcohol is prepared by the following methods:

[0065] S1. Mix the polyvinyl acetate resin and ethanol, the stirring speed is 300r / min, and place it in an electric heating constant temperature drying oven at 45-50°C. After the polyvinyl acetate resin is completely dissolv...

Embodiment 2

[0068] The preparation of embodiment 2 interstitial plugging agent

[0069] Composition of raw materials (parts by weight): 10 parts of expanded polyvinyl alcohol, 7 parts of sodium peroxide, 5 parts of sodium bicarbonate, 5 parts of sodium borate, 3 parts of sustained-release microcapsule breaker (the content is ammonium persulfate), 35 parts of sulfonated tannin extract, 15 parts of montmorillonite powder and 30 parts of isopropanol.

[0070] Expanded polyvinyl alcohol is prepared from the following raw materials: 20 parts of polyvinyl acetate resin, 12 parts of sodium carboxymethylcellulose, 40 parts of ethanol, 2.5 parts of NaOH, 1.5 parts of acetic acid, and 3 parts of barium chloride.

[0071] Expanded polyvinyl alcohol is prepared by the following methods:

[0072] S1. Mix the polyvinyl acetate resin and ethanol, the stirring speed is 500r / min, and place it in an electric heating constant temperature drying box at 50°C. After the polyvinyl acetate resin is completely d...

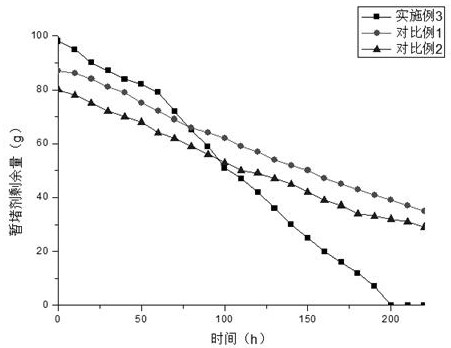

Embodiment 3

[0075] The preparation of embodiment 3 interstitial plugging agent

[0076] Composition of raw materials (parts by weight): 7 parts of expanded polyvinyl alcohol, 5 parts of sodium peroxide, 3 parts of sodium bicarbonate, 4 parts of sodium borate, 2 parts of slow-release microcapsule breaker (the content is ammonium persulfate), 30 parts of sulfonated tannin extract, 12 parts of montmorillonite powder and 22 parts of isopropanol.

[0077] Expanded polyvinyl alcohol is prepared from the following raw materials: 15 parts of polyvinyl acetate resin, 10 parts of sodium carboxymethyl cellulose, 30 parts of ethanol, 1.5 parts of NaOH, 1 part of acetic acid, and 2 parts of barium chloride.

[0078] Expanded polyvinyl alcohol is prepared by the following methods:

[0079] S1. Mix polyvinyl acetate resin and ethanol, stir at 400r / min, place in an electric heating constant temperature drying oven at 45-50°C, and slowly add 5wt% NaOH ethanol after the polyvinyl acetate resin is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com