Rock slope plant growth substrate and preparation method thereof

A plant growth and slope technology, which is applied in the fields of botanical equipment and methods, planting substrates, fertilizers made of biological waste, etc., can solve the problems of poor water and fertilizer retention capacity, hardening and cracking of the guest soil layer, slow growth of plants, etc. Achieve the effect of increasing water retention capacity, good absorption rate and water absorption speed, and improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A rocky slope plant growth substrate, specific implementation steps: 15 parts of organic rice husks (rice husks) and 10 parts of slow-release fertilizer and 100 parts of soil (this soil is selected from nature with the required physical and chemical properties suitable for plant growth) Soil, the sand content of the soil is not more than 5%, and then dried, crushed, and sieved, the particle size is 0.5~10mm.) Mix evenly, and then add 0.1 part of expanded potato starch, 0.1 part of hydroxypropyl methylcellulose Dissolve in 25ml of water, slowly pour into the above soil, stirring constantly. Afterwards, dissolve 0.1 part of calcium chloride and 0.25 part of sodium silicate in 25ml of water, mix well, pour the above solution into a beaker with loam, stir continuously with a glass rod, and stir evenly. According to the slope plant species, the plant growth substrate is sprayed on the rocky slope.

Embodiment 2

[0016] A rocky slope plant growth substrate, specific implementation steps: mix 15 parts of organic rice husk (7.5 parts of rice husk, 7.5 parts of sawdust) and 10 parts of slow-release fertilizer with 100 parts of soil (this soil is selected from all kinds of soil suitable for plant growth) Soil in nature that requires physical and chemical properties, the sand content of the soil is not more than 5%, and then the particle size is 0.5~10mm after drying, crushing, and sieving.) Mix evenly, and then mix 0.25 parts of expanded potato starch, 0.25 parts Hydroxypropyl methylcellulose was dissolved in 30ml of water, slowly poured into the above soil, and kept stirring. Afterwards, dissolve 0.1 part of calcium chloride and 0.25 part of sodium silicate in 30ml of water, mix well, pour the above solution into a beaker filled with loam, stir continuously with a glass rod, and stir evenly. According to the slope plant species, the plant growth substrate is sprayed on the rocky slope.

Embodiment 3

[0018] A rocky slope plant growth substrate, specific implementation steps: 15 parts of organic rice husk (sawdust) and 10 parts of slow-release fertilizer and 100 parts of soil (this soil is selected from the natural world with the required physical and chemical properties suitable for plant growth) Soil, the sand content of the soil is not more than 5%, and then dried, crushed, and sieved, the particle size is 0.5~10mm.) Mix evenly, dissolve 0.5 parts of expanded potato starch, 0.1 parts of hydroxypropyl methylcellulose In 40ml of water, slowly pour into the above soil, stirring constantly. Then dissolve 0.1 part of calcium chloride and 0.25 part of sodium silicate in 40ml of water, mix well, pour the above solution into a beaker filled with loam, stir continuously with a glass rod, and stir evenly. According to the slope plant species, the plant growth substrate is sprayed on the rocky slope.

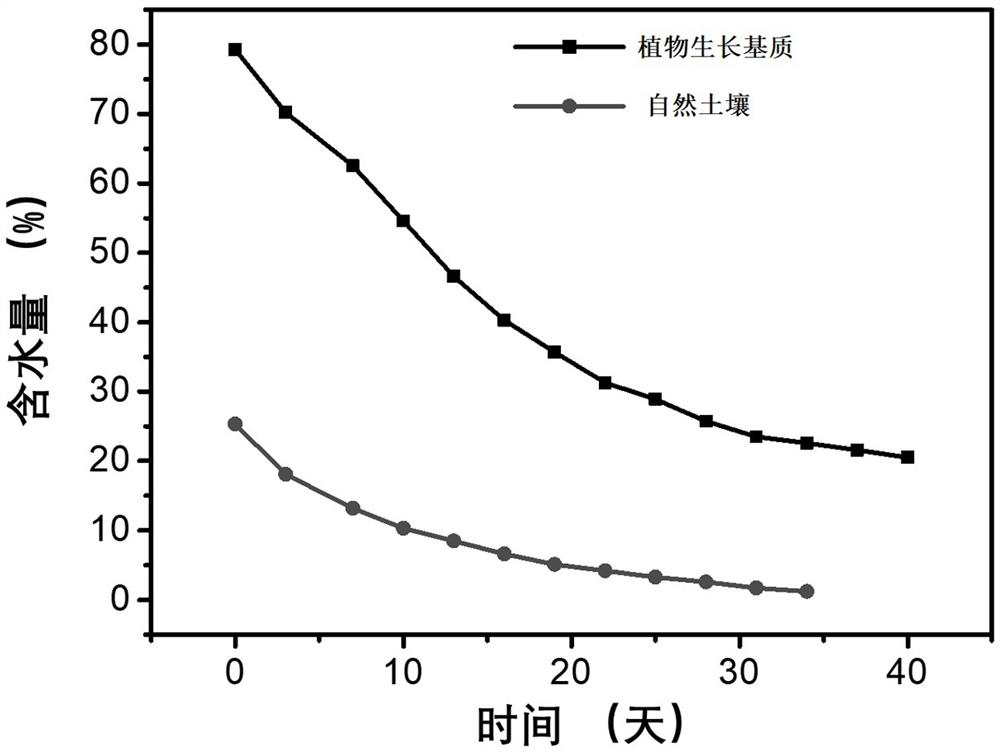

[0019] The rock slope plant growth substrate prepared by this feed ratio has th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com