Vegetable oil-based flexible amine curing agent, preparation method thereof and vegetable oil-based tough epoxy resin

A technology of tough epoxy resin and oil-based flexible amine, which is applied in the preparation of cyanide reaction, chemical instruments and methods, and the preparation of organic compounds. It can solve the hidden dangers of solvent residues, increase energy consumption, and affect material properties, etc. problems, to eliminate hidden dangers of solvent residues, reduce equipment requirements, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The vegetable oil-based tough epoxy resin provided in this embodiment is prepared through the following steps:

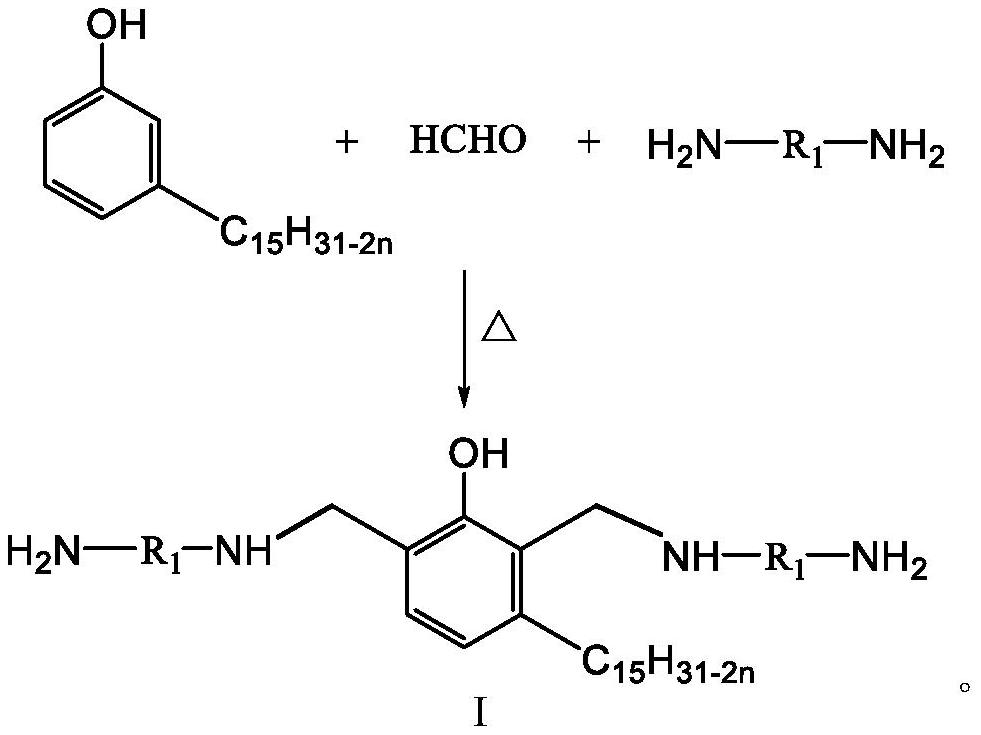

[0035] (1) Preparation of vegetable oil-based flexible amine curing agent

[0036] A. Add 150g of cardanol and 60.1g of ethylenediamine into a four-necked flask with mechanical stirring, and heat it to 80°C under nitrogen protection. After 2 hours of reaction, slowly add 30g of formaldehyde in batches, and react at 120°C for 4 After 1 hour, the moisture and unreacted ethylenediamine were removed under vacuum to obtain intermediate 1.

[0037] B, 180g of intermediate 1 is added in the normal pressure reactor, the temperature is raised to 100°C, then the mixed solution of 1.22g of triphenylphosphine (accelerator) and 63.0g of epoxidized soybean oil is added dropwise, The reaction time was 8 hours at 100°C, the temperature was lowered, and the material was discharged to obtain a vegetable oil-based flexible amine curing agent 1. The measured active hydrogen eq...

Embodiment 2

[0041] The vegetable oil-based tough epoxy resin provided in this embodiment is prepared through the following steps:

[0042] (1) Preparation of vegetable oil-based flexible amine curing agent

[0043] A. Add 150g of cardanol and 103.2g of diethylenetriamine into a four-necked flask with mechanical stirring, and heat to 80°C under nitrogen protection. After 2 hours of reaction, slowly add 30g of formaldehyde in batches and react at 120°C After 4 hours, the moisture and unreacted diethylenetriamine were removed under vacuum to obtain intermediate 2.

[0044] B. Add 180g of intermediate 2 into the normal pressure reactor, heat up to 100°C, and then drop the mixed solution of 1.33g of N,N-dimethylbenzylamine (accelerator) and 84.0g of epoxidized soybean oil Add in the way of adding, react at 100°C for 8 hours, cool down and discharge. The measured active hydrogen equivalent was 130.6.

[0045] (2) Preparation of epoxy resin

[0046] Take 177.4g vegetable oil-based flexible a...

Embodiment 3

[0048] The vegetable oil-based tough epoxy resin provided in this embodiment is prepared through the following steps:

[0049] (1) Preparation of vegetable oil-based flexible amine curing agent

[0050] A. Add 150g of cardanol and 146.2g of triethylenetetramine into a four-necked flask with mechanical stirring, and heat it to 80°C under nitrogen protection. After 2 hours of reaction, slowly add 30g of formaldehyde in batches and react at 120°C After 4 hours, the moisture and unreacted triethylenetetramine were removed under vacuum to obtain intermediate 3.

[0051] B. Add 180g of intermediate 3 into the normal pressure reactor, heat up to 120°C, and then drop the mixture of 1.36g of N,N-dimethylbenzylamine (accelerator) and 90.9g of epoxidized soybean oil Add in the way of adding, react at 100°C for 8 hours, cool down and discharge. The measured active hydrogen equivalent was 124.8.

[0052] (2) Preparation of epoxy resin

[0053] Take 172.2g vegetable oil-based flexible ami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com