A preparation process and system for producing high-grade titanium-rich material from ilmenite

A preparation process and technology of ilmenite, applied in furnaces, magnetic separation, furnace types, etc., can solve the problems of large exhaust gas treatment system, large investment and floor space, high maintenance and repair costs, and avoid the phenomenon of ring formation and equipment. The effect of low failure rate and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

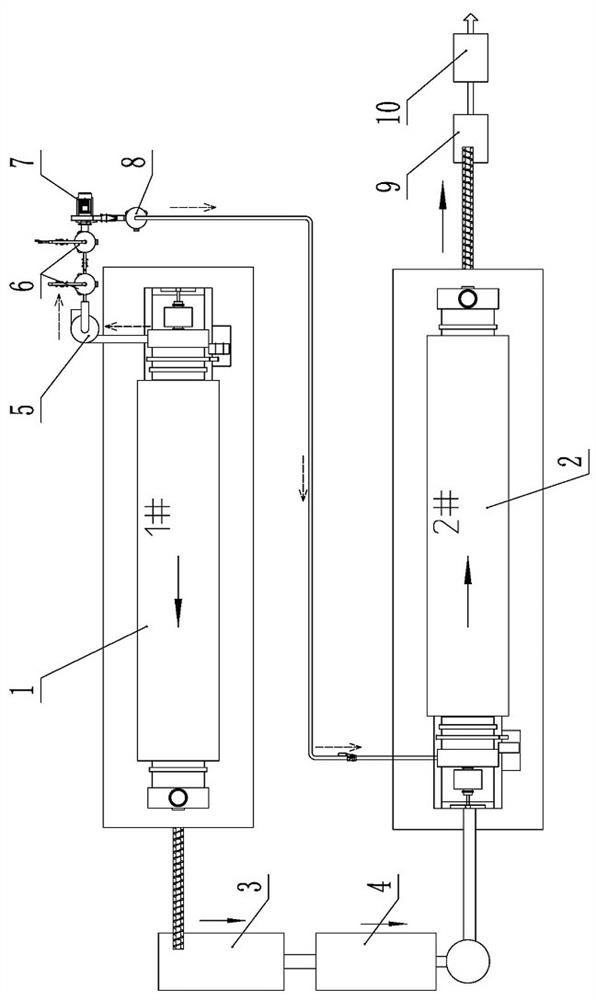

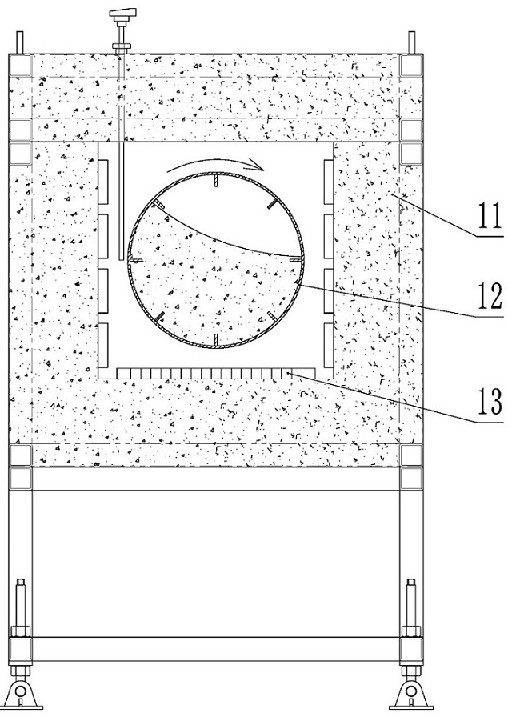

[0038] In terms of mass percentage, 78% imported ilmenite, 20% bituminous coal and 2% lime were sequentially added into the first rotary kiln and mixed evenly. The primary reduction temperature was controlled at 1150°C, and the reduced raw materials were obtained after holding for 1 hour. 4000ppm, furnace pressure is +4mm water column, CO / CO 2 The concentration ratio is 94%. After cooling to below 60°C, low-melting inorganic substances, coal powder and non-magnetic substances are removed by screening and magnetic separation to obtain pure titanium-iron mosaics with uniform particle size; the generated water vapor and tar , dust and CO, H 2 , CO 2 The reducing gas and inert gas pass through the high-temperature cyclone dedusting, oil-gas separator, Roots blower and gas cabinet in sequence, and finally the reducing gas and inert gas left in the gas cabinet are transported to the second rotary kiln through pipelines; then in the second rotary kiln The reduction temperature is 1...

Embodiment 2

[0040] In terms of mass percentage, 62% imported ilmenite, 35% bituminous coal and 3% lime were sequentially added into the first rotary kiln and mixed evenly. The primary reduction temperature was controlled at 900°C, and the reduced raw materials were obtained after holding for 3 hours. 5000ppm, furnace pressure is +3mm water column, CO / CO 2 The concentration ratio is 95%. After cooling to below 60°C, low-melting inorganic substances, coal powder and non-magnetic substances are removed by screening and magnetic separation to obtain pure titanium-iron mosaics with uniform particle size; the generated water vapor and tar , dust and CO, H 2 , CO 2 The reducing gas and inert gas pass through the high-temperature cyclone dedusting, oil-gas separator, Roots blower and gas cabinet in sequence, and finally the reducing gas and inert gas left in the gas cabinet are transported to the second rotary kiln through pipelines; then in the second rotary kiln The reduction temperature is 1...

Embodiment 3

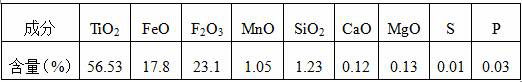

[0042] In terms of mass percentage, add 70% Panxi ilmenite, 27% bituminous coal and 3% lime in sequence to the first rotary kiln and mix evenly. The primary reduction temperature is controlled at 1050°C. 5000ppm, furnace pressure +3mm water column, CO / CO 2 The concentration ratio is 94%. After cooling to below 60°C, low-melting inorganic substances, coal powder and non-magnetic substances are removed by screening and magnetic separation to obtain pure titanium-iron mosaics with uniform particle size; the generated water vapor and tar , dust and CO, H 2 , CO 2 The reducing gas and inert gas pass through the high-temperature cyclone dedusting, oil-gas separator, Roots blower and gas cabinet in sequence, and finally the reducing gas and inert gas left in the gas cabinet are transported to the second rotary kiln through pipelines; then in the second rotary kiln The reduction temperature is 1250°C, and the reduction material is obtained after 2 hours of heat preservation. The oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com