Quality method complexometric titration nickel-cobalt-manganese content detection method

A complexometric titration and detection method technology, applied in the detection field, can solve problems such as large errors, and achieve the effect of eliminating specification errors and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Part I Reagents, Apparatus and Equipment

[0040]

[0041]

[0042]

[0043] The second part of the test process

[0044] Flow chart

[0045] Step 1: Titration of total nickel, cobalt and manganese by mass method

[0046] Operation process: The sample is digested under the heating condition of hydrochloric acid or aqua regia, and after diluting with pure water to a certain volume; titrate with EDTA standard solution, and calculate the total content of nickel, cobalt and manganese based on the consumption of EDTA standard titration solution.

[0047] Digestion: Weigh about 0.5g of the sample, record the sample mass m, put the sample in a 100mL beaker, add appropriate amount of hydrochloric acid or aqua regia, heat and digest in a fume hood, cover the mouth of the 100mL beaker with a watch glass, until the sample is completely digested , add an appropriate amount of pure water to dilute, and rinse the watch glass for 3-5 times;

[0048] Mass constant volume: c...

Embodiment 2

[0061] 1: titration of the total amount of nickel, cobalt and manganese by mass method, adopt the method of step 1 of embodiment 1, obtain the following results.

[0062]

[0063] 2: ICP nickel cobalt manganese component detection

[0064] Standard Curve Development

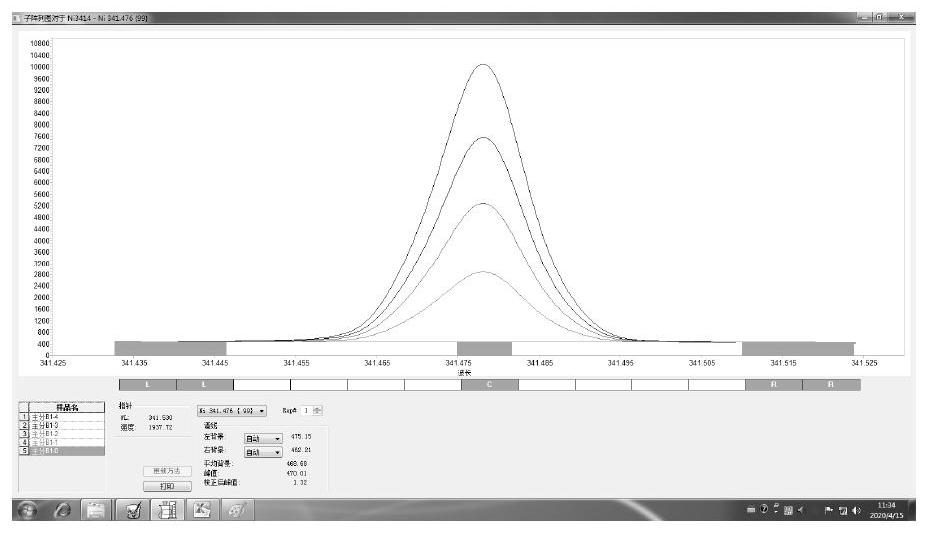

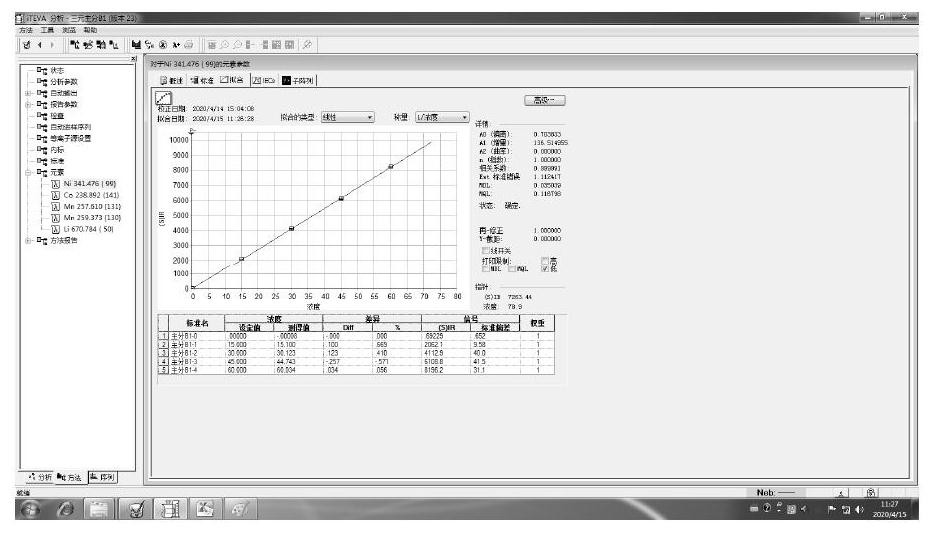

[0065] 2.1 Nickel standard solution spectral characteristic peaks and curves, such as figure 1 and figure 2 ;

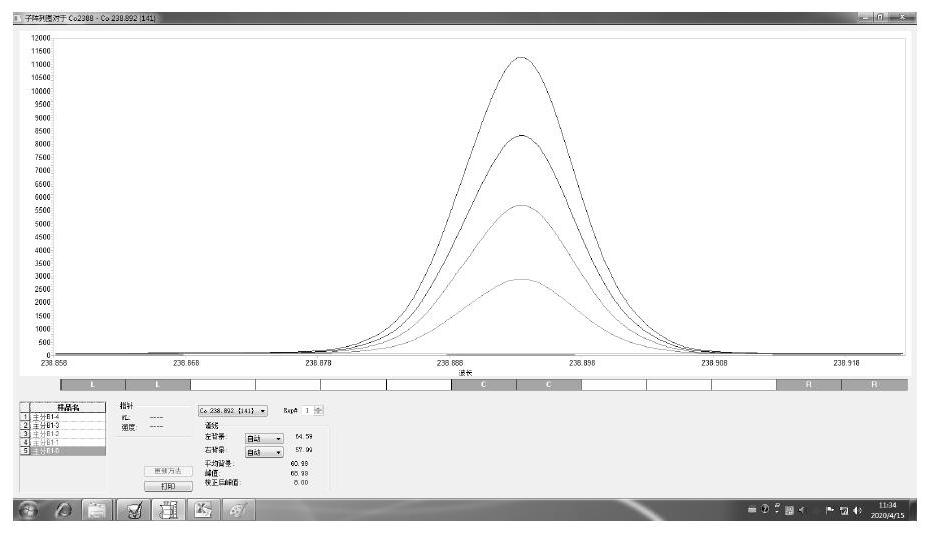

[0066] 2.2 Spectral characteristic peaks and curves of cobalt standard solution, such as image 3 and Figure 4 ;

[0067] 2.3 Spectral characteristic peaks and curves of manganese standard solution, such as Figure 5 and Figure 6 ;

[0068] The test results of the original ICP component of the sample are as follows:

[0069]

[0070] Accurate component results after calculation

[0071]

Embodiment 3

[0073] This embodiment mainly investigates the influence of the selection of the buffer solution on the measurement accuracy of the mass method.

[0074] The nickel-cobalt-manganese standard solution adopted in the present embodiment is: a standard solution with a total concentration of nickel, cobalt and manganese of 60%;

[0075] 3.1 The influence of ammonia-ammonium chloride buffer solution on the total amount of nickel, cobalt and manganese.

[0076] The experimental method of this step is the same as step 1 of Example 1, and the pH value is adjusted to 9.5-10.5;

[0077] The results obtained by parallel testing 3 times by this method are: the total concentration of nickel, cobalt and manganese is 60.11%, 60.12%, 60.15%, and the average value is 60.13%;

[0078] 3.2 The influence of borax buffer solution on the total amount of nickel, cobalt and manganese.

[0079] The experimental method of this step is the same as step 1 of Example 1, and the pH value is adjusted to 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com