Environment-friendly bolt type power electronic rectification chip forming process

A technology of rectifier chips and power electronics, which is applied in circuits, electrical components, manufacturing tools, etc., can solve problems such as hindering the health of workers and excessive lead solder, and achieve the effect of improving environmental protection index, good appearance and performance, and expanding the application market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

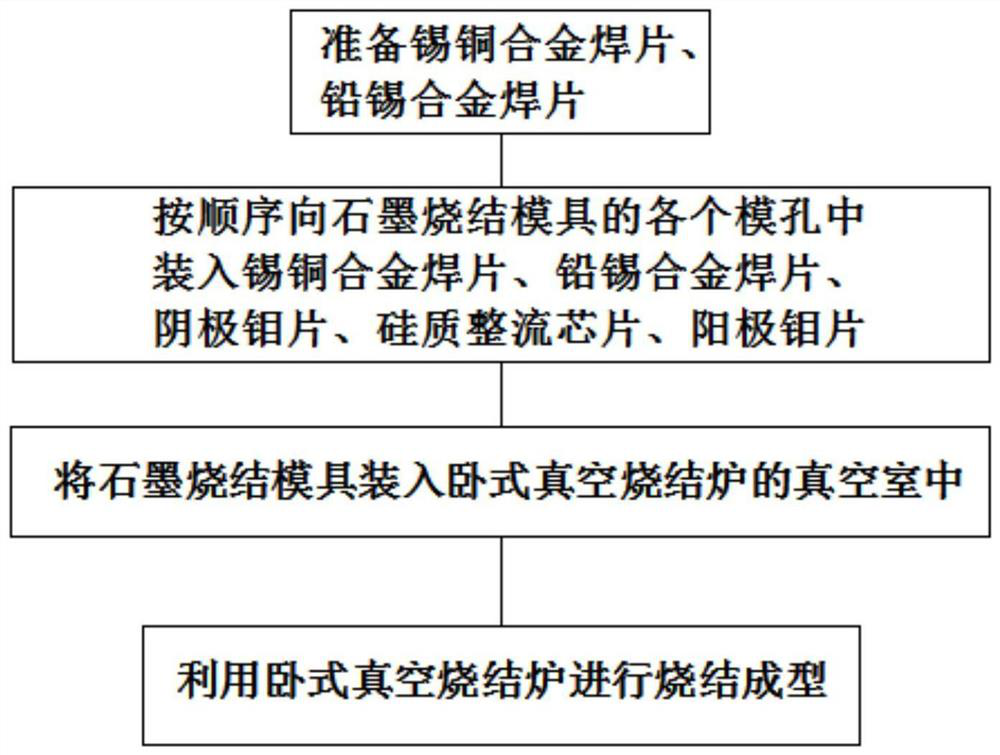

[0037] like figure 1 As shown, an environmentally friendly bolt-type power electronic rectifier chip molding process includes the following steps:

[0038] (1) Prepare multiple tin-copper alloy solder sheets and lead-tin alloy solder sheets, wherein the weight percentage of tin in each tin-copper alloy solder sheet is 96%~98%, and the weight percentage of copper is 4%~2%, And the proportion of tin and the proportion of copper in multiple tin-copper alloy solder pieces are the same;

[0039] In step (1), the weight percentage of tin in the tin-copper alloy solder sheet may be 96%, or 97%, or 98%, and the weight percentage of copper may be 4%, or 3%, or 2%. Wherein the optimal value is 97% by weight of tin and 3% by weight of copper. The weight percentage of each component in the lead-tin alloy solder sheet is the same as that of all the lead-tin alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com