Manufacturing method of new energy intelligent automobile printed circuit board

A technology for printed circuit boards and smart cars, which is applied in the fields of printed circuit manufacturing, laminated printed circuit boards, printed circuits, etc., and can solve problems such as back-drilling blockage, reducing the work efficiency of technicians, and restricting the development of new energy vehicles. Achieve the effect of reducing the possibility of blocking and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

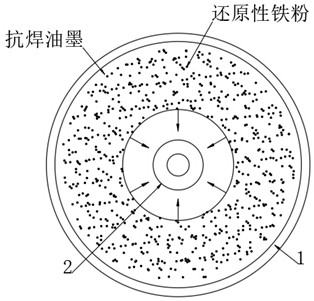

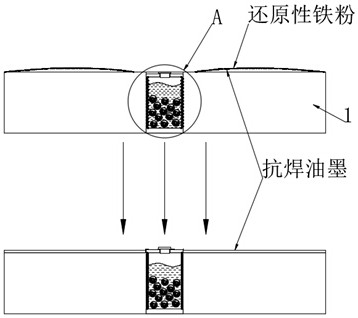

[0043] see Figure 1-2 A method for manufacturing a printed circuit board of a new energy smart car, comprising a printed circuit board 1, the upper end of the printed circuit board 1 being drilled with a back-drilled hole 2, comprising the following steps:

[0044] S1. Stack a plurality of core boards in sequence, press the plurality of core boards into a printed circuit board 1 by means of a punching device, and drill back-drilled holes 2 on the printed circuit board through a drilling device;

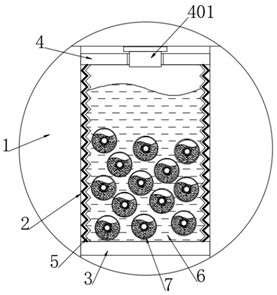

[0045] S2. Place the printed circuit board 1 after the back-drilled hole 2 is drilled on the workbench, add reducing iron powder to the solder resist ink and stir evenly, and then add an ink traction device to the back-drilled hole 2;

[0046] S3. Put the solder resist ink added with reduced iron powder on the surface of the printed circuit board 1, and surround the coated solder resist ink layer around the back drill hole 2, and evenly absorb the solder resist ink to the back drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com