Nitrogen-phosphorus doped two-dimensional carbon/silicon compound and preparation method and application thereof

A compound, nitrogen and phosphorus technology, applied in the preparation/purification of carbon, silicon, electrode manufacturing, etc., to achieve the effect of simple operation, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

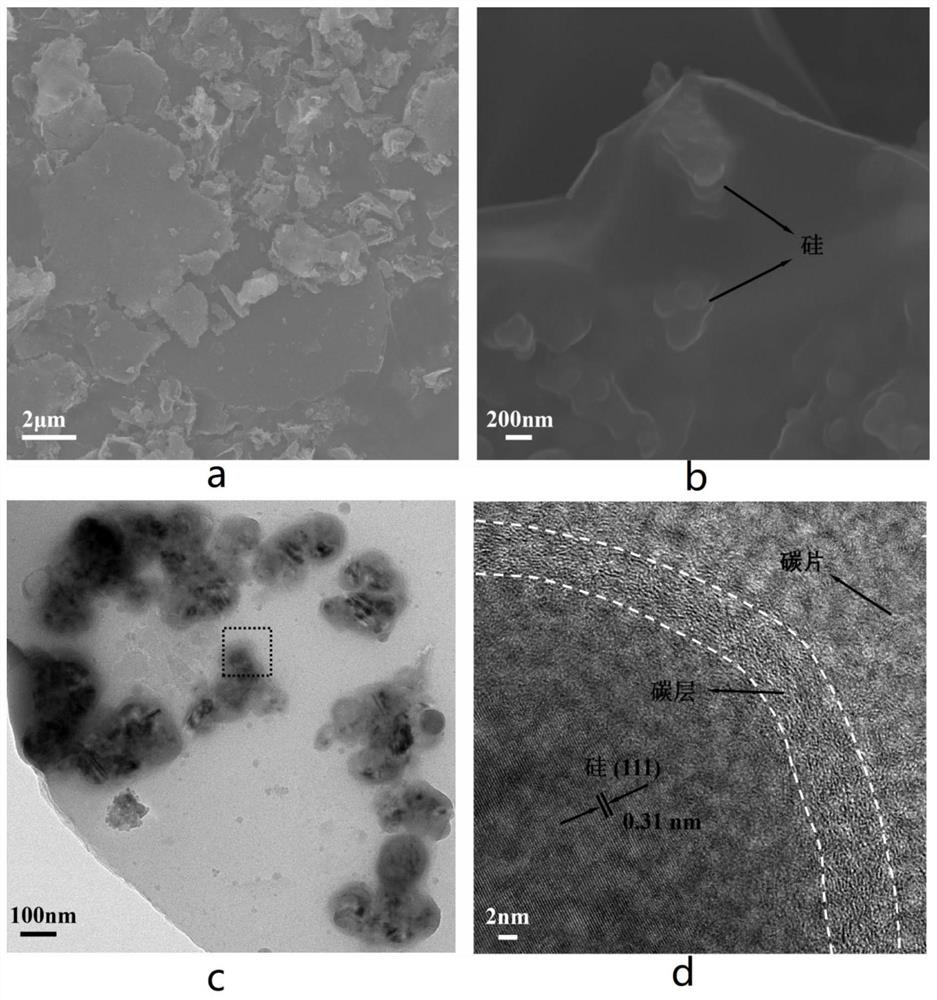

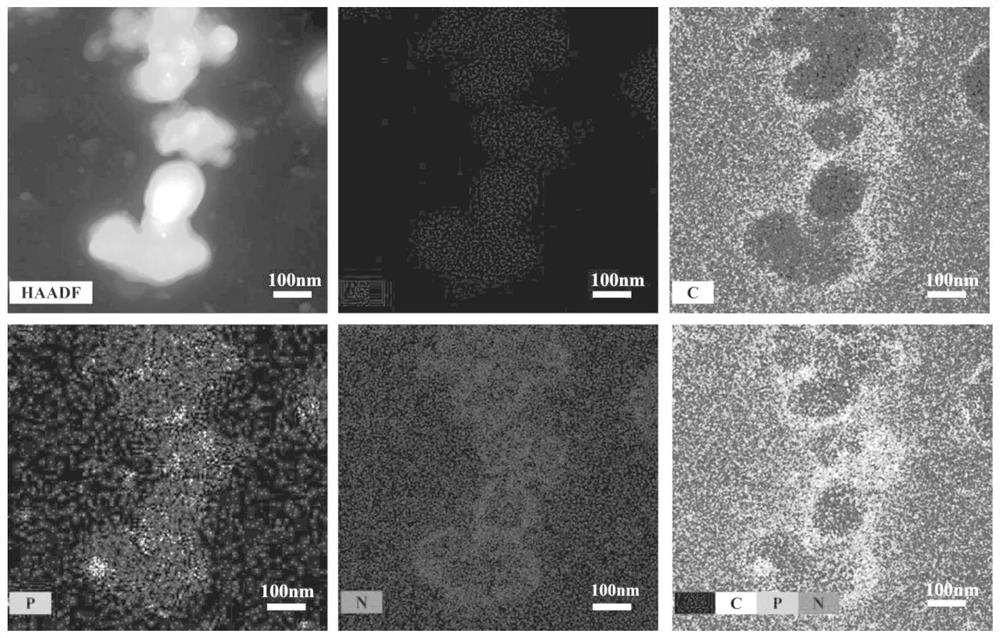

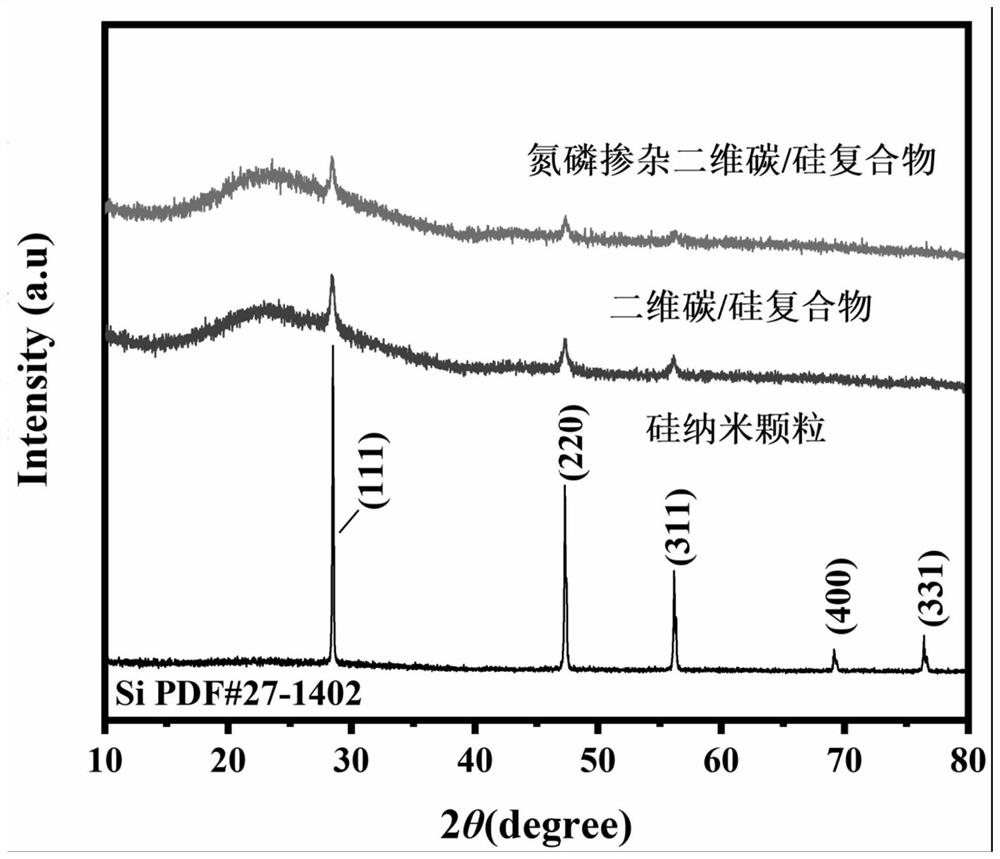

[0035] Example 1: Preparation of nitrogen and phosphorus doped two-dimensional carbon / silicon composite

[0036] Step 1: Dissolve 1g of glucose in 10mL of deionized water, sonicate until uniform, then add 50mg of elemental silicon with a size of 100nm, sonicate until uniform, then add 10g of NaCl solid powder, sonicate evenly, and dry the mixture in a drying oven at 80°C for 12h , The resulting blocky solid is ground into a sufficiently fine powder in a mortar.

[0037] (2) Place the powder prepared above in a tube furnace with nitrogen as a protective gas, heat up to 750°C at a heating rate of 5°C / min, calcinate for 2 hours, then cool with the furnace, and finally deionize with 200mL The fired powder was etched with water for 12 hours to remove the NaCl template, and then dried in an oven at 80° C. for 12 hours to obtain a two-dimensional carbon / silicon composite.

[0038] (3) Disperse 100mg of two-dimensional carbon / silicon composite and 0.25g of melamine in 100ml of deioni...

Embodiment 2

[0049] The difference from Example 1 is that the carbon source is replaced by starch to obtain a nitrogen and phosphorus doped two-dimensional carbon / silicon composite.

Embodiment 3

[0051] The difference from Example 1 is that the carbon source is replaced by citric acid to obtain a nitrogen-phosphorus-doped two-dimensional carbon / silicon composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com